for Roughing and Finishing Ti (C, N) -Based Cermet Rods

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Bathroom Shelves & Towel Racks

changsha langfeng metallic material co.ltd

- Verified Certificate

-

9

| Product name | for Roughing and Finishing Ti (C, N) -Based Cermet Rods | Certification | - |

|---|---|---|---|

| Category | Bathroom Shelves & Towel Racks | Ingredients | - |

| Keyword | ticn cermet blanks , ticn cermet rods , ball nose endmill , ni co alloy | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

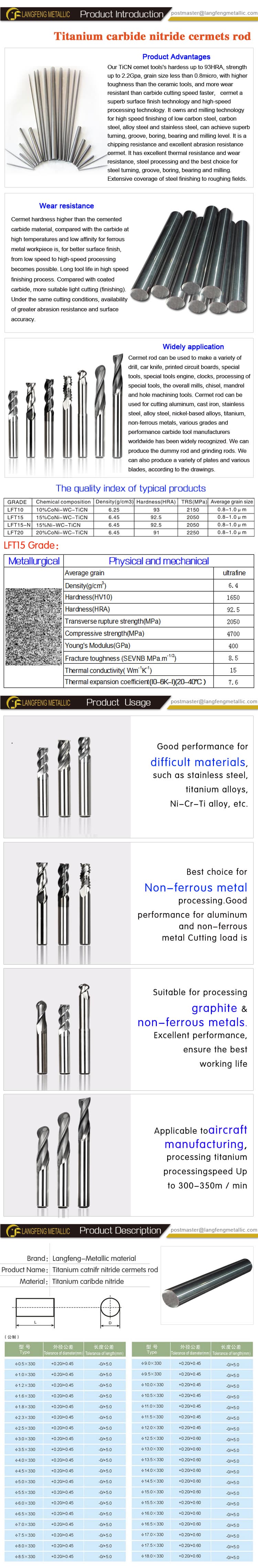

Our company production of Ti (C, N) based cermet blanks (Grade:LFT15), hardness up to 92.5HRA, strength up to 2.0-2.1Gpa.Grain size less than 0.8 micron,belong to the ultrafine metal ceramics.By adding carbon titanium nitride and other metal and ceramic powder additive,Having a fine structure,can guarantee the quality of the surface of the workpiece in various of cutting conditions.Having excellent thermal shock resistance and the optimal wear resistance and toughness,And having excellent resistance to plastic deformation and bue.

Cermet CNC cutting tools toughness higher than ceramic tools,More wear-resistant than carbide cutting speed faster,metal ceramics have excellent surface polishing technology and high speed machining technology.With high-speed finishing and milling technology for low-carbon steel, carbon steel, alloy steel and stainless steel,to achieve superb turning, groove, boring, bearings and milling level.Having chipping resistance and wear resistance superior cermet.Having excellent thermal conductivity and wear resistance,is steel processing the best choice,suitable for steel turning, groove, boring, bearings and milling.Covering a wide range of steel finishing to roughing field.

Metal ceramic hardness is higher than that of sintered hard alloy materials ,compared with carbide tips.Ceramic metal and black metal workpieces are of low affinity under high temperature conditions,can get a better surface finish,from low speed to high speed processing is possible.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- liuzhaohui

- Address

- changsha city hunan province china

- Product Category

- Metal & Metallurgy Machinery

- Year Established

- 2009

- No. of Total Employees

- 101-500

- Company introduction

-

Changsha Langfeng Metallic Material Co.,Ltd, founded in 2009 in Changsha Longping High-Tech Park, Hunan Province ,China. Langfeng Metallic Material has grown not only the manufacturer of new material in military rocket systems , coating materials, grain inhibitor and additives in cemented carbide, but also an important provider of cermet blank for CNC/NC cutting tools, especially on die /mould processing to the world at large.

The company has 16,000 square meters of standard factory, covering 50 acres, 180 employees. There are a full range of testing equipment and strong technical force; we have a 20-person R & D team, including two academicians, five Professors, eight Ph.D. We maintain a long-term technical cooperation with the Chinese Academy of Science, Powder Metallurgy Research Institute of Central South University, Changsha Research Institute of Mining and Metallurgy.

- Main Markets

-

Canada

Canada

France

France

Germany

Germany

India

India

Iraq

Iraq

Italy

Italy

Japan

Japan

U.S.A

U.S.A

- Main Product

China

China