S-Prodis (Manufacturing Simulator)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- factory, manufacturing, simulator, productiron

- Category

- Computer Software

ESE Technology Co.,Ltd.

- Verified Certificate

-

11

| Product name | S-Prodis (Manufacturing Simulator) | Certification | - |

|---|---|---|---|

| Category | Computer Software | Ingredients | - |

| Keyword | factory , manufacturing , simulator , productiron | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

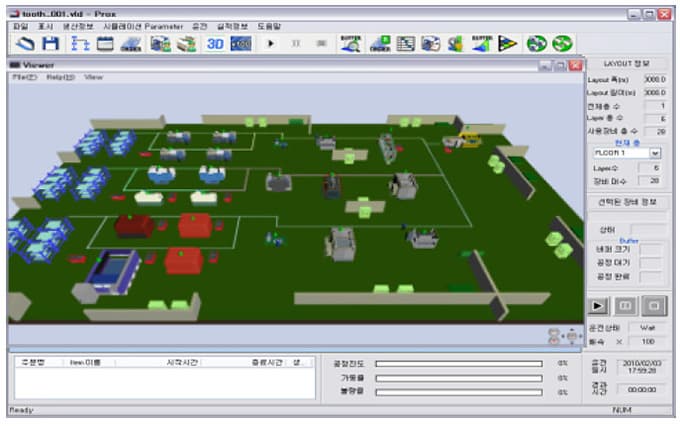

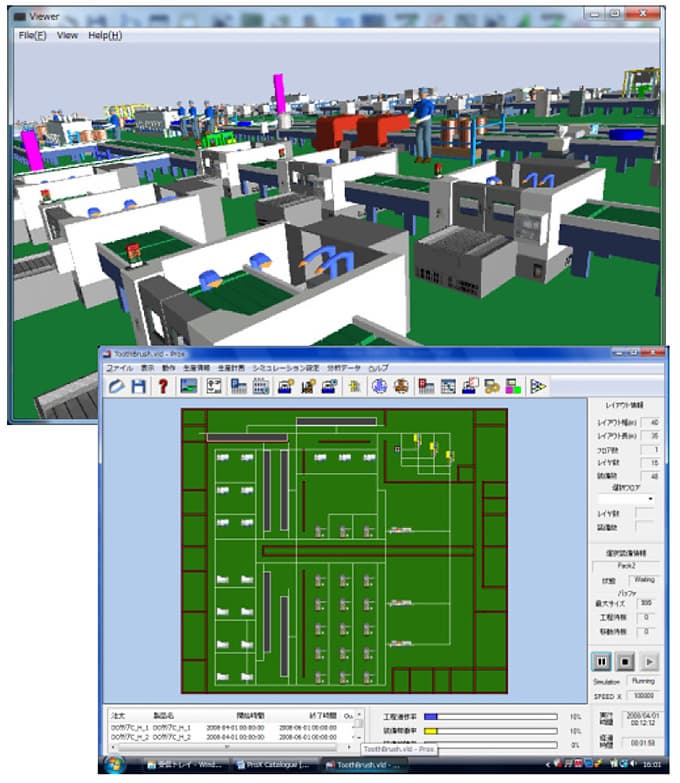

S-Prodis (Manufacturing Simulator)

│ Description │

S-Prodis is the solution for the improvement of manufacturing line which can easily find the bottleneck of production line and support the improvement of line by simulation analysis data.

│ Effects │

User can easily build the production line by using Process Editor and Layout Editor in short time , Many simulation parameter support you to simulate and analysis your production line.

The following effects can be achieved through the analysis of various simulation results.

1) Improved productivity

2) Effective Line balancing

3) Most appropriate machine and the worker's arrangement

4) Reduction in transportation movement by the best layout.

5) Shorting the delivery date and best production plan.

6) Reduction in stock by appropriate lot input on time

│ Features & Functions │

1. Scheduling Function

1) Setting production plan

2) 8 dispatching rule(SPT,FIFO,EDO,LWKR,etc)

3) Automatic calculation of necessary lot amount

4) Import of excel file(production plan)

2. Simulation Function

1) Setting machine parameters(ability, failure rate, restoration time, group, etc)

2) Setting transfer equipment parameters(number, speed, transfer lot amount, failure rate, etc)

3) Setting number of buffer

4) Setting holidays, rest time, machining , worker working time

5) Setting worker parameters(number, group, absent rate, etc)

6) Setting warehouse parameters ( rack size, priority, etc)

7) 3D View & Camera path setting

8) Hierarchy layout simulation

9) Simulation speed setting

3. Process

1) Process setting by flow chart diagram

2) Process division merging function

3) Cell manufacturing setting

4) Item production link function

5) Lot size and Batch size setting

6) Before setup and after setup setting

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Chunkyung Song

- Address

- Chunui Technopark 2th 202 Wonmi-gu, Bucheon-si Gyeonggi-do

- Product Category

- Computer Software,Education Supplies,Electrical Components & Telecoms

- Year Established

- 2004

- No. of Total Employees

- 1-50

- Company introduction

-

ESE Technology is one of the leading supplier of Manufacturing simulation and high technical training kit in Korea from 2004.

Our products is used in manufacturing company and main training center in Korea and we also export to Japan.

Our products are based on simulation technology and easy man machine interface. Especially our new product ESEMM is a new concept that makes learning automation a realistic, safety and fun through PLC programming training .

- Main Markets

-

Japan

Japan

- Main Product

Related Products

VR Firefighting Danger Prediction Training System - DAPREs

Art Odyssey (Animation)

Visual CG 3D

OMV+

Virtual Fitting

South Korea

South Korea