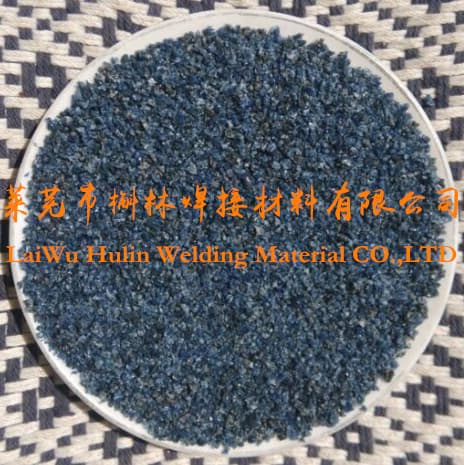

Welding Flux Powder HJ107, Fused Flux

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Panding

- Payment Terms

- L/C,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Welding Fluxes

Laiwu Hulin Welding Material Co., Ltd.

- Verified Certificate

-

9

| Product name | Welding Flux Powder HJ107, Fused Flux | Certification | - |

|---|---|---|---|

| Category | Welding Fluxes | Ingredients | - |

| Keyword | welding flux , submerged arc welding flux , fused flux hj107 , welding flux hj107 | Unit Size | - |

| Brand name | Panding | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

HJ107: GB/T 17854-1999 F308-H0Cr21Ni10

F308L-H00Cr21Nni10

LH-HJ107 is a kind of smelting-type non-Mn mid-Si and mid-F flux,which appears grey-black pumice-like particles with the mesh of 10-60(2.0-0.3mm) or 8-40(2.5-0.45mm). It uses direct-current main. When it is used under higher arc voltage, the penetration is shallow,the arc is stable and the appearance of weld is pleasing to the eyes.Meanwhile,the consumption of flux is low and it is easy to detach the welding slag.Because it contains more CaF2 and also cryolite is added in,its abliity of anti-porosity and anti-cracking is greatly improved.In addition,adding Cr203 into it not only makes the weld face appear pumice-like but also reduces the loss of Cr in the process of stainless welding.

Usage:

Excellent surfacing layers can be gained when it is used in the build-up welding in conjunction with appropriate welding wires or bands(such as HOCr21Ni10,HOCr20Ni1OTi,HOOCr21Ni10,HOOCr24Nb,HOCr16Mn16,etc).It is suitable for the build-up welding of nuclear containers and petrochemical equipment's corrosion-proof layers,stain-less clad layers and pressure vessels.In conjunction with HOCr16Mn16,it can be used in the build-up welding of the switch of austenitic manganese steel(Mn13) and welding of Nb-contained stainless steel,etc.

Performance of Surfacing Layers:

(It can be used in the transition-layer welding in conjunction with HOOCr26Ni12 and in the build-up welding of 50mm-thick 18MnMoNb steel plate in conjunction with HOOCr21Ni10 as the surface-layer welding band.)

Cautions:

1.Impurities on the welding surface must be removed before welding,such as oil soil,moisture,iron rust,etc.

2.The flux must be baked for 2 hous under the temperature of 250-300ºC before it is used.

(Chemical Composition)(%)

| SiO2 | CaF2 | Al2O3 | MgO+CaO | S | P | |

| 26~30 | 20~30 | 24~30 | 14~21 | ≤0.05 | ≤0.05 | ≤10 |

| Tested Items | s (Mpa) |

δ5 |

| Common Results | ≥520 | ≥35% |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T,Western Union | Shipping time | Negotiable |

- President

- Nianhao Li

- Address

- Niuquan Industrial Park

- Product Category

- Welding Fluxes

- Year Established

- 1999

- No. of Total Employees

- 101-500

- Company introduction

-

LAIWU HULING WELDING is one of leading biggest manufacturer of Submerged ARC welding flux in China. The annual capacity of production is growing and up to12000 metric tons of agglomerated flux and 5000 metric tons of fused flux. The factory has established the R&D laboratory with the advanced inspection equipments in field of welding materials. Our company is located at Laiwu City near by the Jinan International Airport, and also is near the TAISHAN Mount of Shandong Province, China.

The Submerged-ARC welding flux has been approved and passed the inspection of quality with the province grade and the national grade in China. We strictly executed and produced the welding flux according to the industrial standards ofGB/T 5293-1999, GB/T 12740-2003, GB/T17854-1999 and the China Classification Society-1996 completely. Our quality management has passed IS09001-2008 Quality System Certification.

The welding flux has been widely used in the Chemical engineering equipment, Heavy machinery, Pressure vessel, Boiler, Gas cylinder body, Spiral welded steel pipe, Steel structure building H-beam steel etc. We have been exported the welding flux to India, Indonesia, Egypt, Japan, Philippine and Jordan. The foreign customer usually purchased and preferred to the high quality Agglomerated flux ( LH-SJ101;LH-SJ301;LH-SJ501;LH-HF101G ) and Manganese oxide fused flux.

- Main Markets

-

Canada

Canada

Egypt

Egypt

India

India

Indonesia

Indonesia

Iran

Iran

Jordan

Jordan

- Main Product

China

China