Virgin coconut, palm Oil Press Processing turnkey project

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Oil Pressers

Henan Institute of Grain Machinery Manufacturing Co., Ltd.

- Verified Certificate

-

9

| Product name | Virgin coconut, palm Oil Press Processing turnkey project | Certification | - |

|---|---|---|---|

| Category | Oil Pressers | Ingredients | - |

| Keyword | palm oil press , oil press project , oil processing line , palm oil turnkey project | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Pretreatment process feature:

1) Different combinations of process can process various oil plants in one workshop.

2) Use special intensified pretreatment technology for aroma peanut oil to make it more aroma.

3) Adopt advanced and reliable shelling technology to meet higher requirements for protein content in meal.

4) Extrusion treatment is used for raw materials with hard extraction, large-sized powder, and large capacity, which can reduce residual oil and solvent consumption, and increase the capacity by 50-80%.

5) The new technology of shelling and low-temperature treatment can ensure high protein and least denaturation.

Pretreatment flow chart for Palm oil Production Line

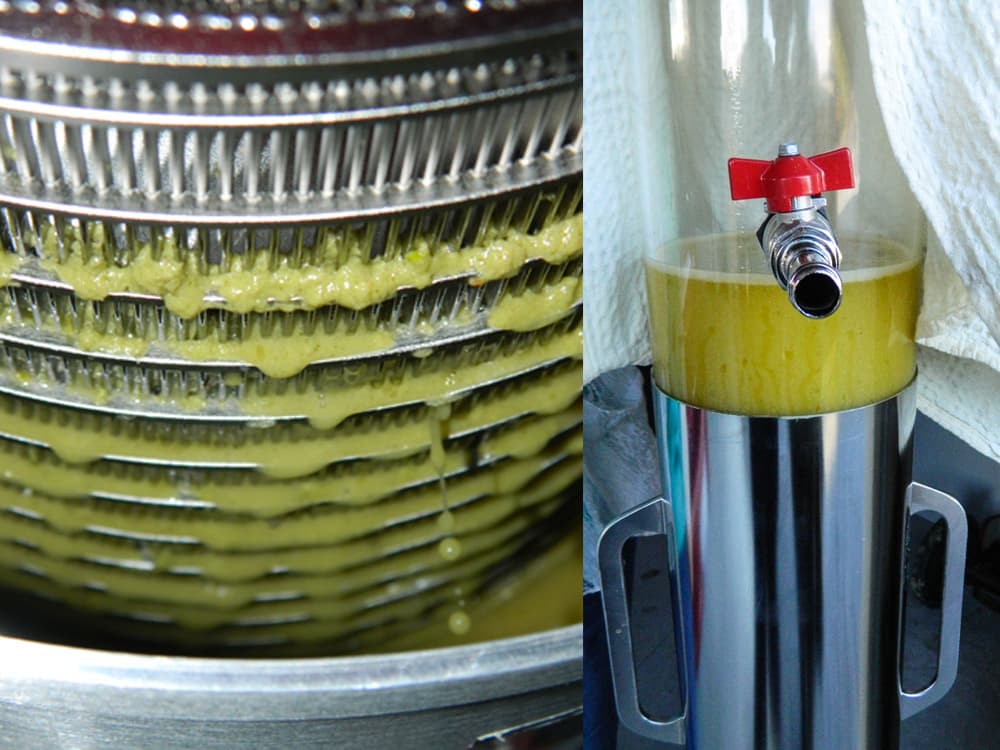

Palm fruit bunch → Sterilization → Threshing → Digesting → Oil press → Clarification → Shell and Kernel recovery

The processing technology parameter:

Capacity : | 5TPH | Oil extraction rates : | 21~23% |

Oil content in FFB : | ≥24% | Kernel content in FFB: | 6% |

Shell content in FFB : | ≥6~7% | Fiber content in FFB : | 12~15% |

Empty bunch content in FFB: | 23% | Press cake proportion in FFB: | 24 % |

Oil content in empty bunch: | 5 % | Moisture in empty bunch : | 63 % |

Solid phase in empty bunch: | 32% | Oil content in press cake: | 6 % |

Water content in press cake : | 40 % | Solid phase in press cake : | 54 % |

Oil content in nut: | 0.08% | Oil content in wet meter heavy phase | 1% |

Oil content on meter solid: | 3.5% | Oil content in final effluent: | 0.6% |

Fruit in empty bunch: | 0.05% | Water in palm kernel | ≤7% |

Kernel in empty bunches: | 0.05% | Kernel content in cyclone fiber: | 0.15% |

Kernel content in LTDS: | 0.15% | Kernel content in dry shell: | 2% |

Kernel content in wet shell: | 2.5% |

|

|

Crude palm oil standard:

FFA : | ≤4 % |

Moisture : | ≤0.1 % |

Dirt: | ≤0.02 % |

Refining flow chart for palm oil

Main Paramaters

Soft water consumption | ≤ 160Kg/H |

Steam consumption | ≤ 300Kg/T oil |

Bleaching earth | 1-3Kg/T oil |

Power consumption | ≤ 22KWH/T oil |

Fuel consumption | 10-20Kg/T oil |

Oil content in waste white clay | ≤ 23% |

Phosphoric consumption | 0.5-1Kg/T oil |

1.Deacidification

Sodium hydroxide antagonize free fatty acids,and subside phospholipids,to remove the insoluble impurities,then after the separation of soapstock, neutral oil was washed in soft water,last drying in vacuum.

2.Decoloration

Used to remove off pigments, bleaching oils and grease dehydrate

3.Deodorization

Using high temperature and high vacuum steam stripping method deodorization temperature commonly 180, vacuum degree 9.3 104 Pa can achieve ideal results

4.Dewaxing

Dewaxing can ensure the colour of the oil to be clear bright at room temperature and frozen temperature. to reduce the oil in the wax content to 10 parts per million to get crystal clear oil.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Pengli Song

- Address

- Room 8637, Six Floor in Grain College, Henan University of Technology, Zhengzhou, China

- Product Category

- Agricultural Equipment,Agriculture Product Processing,Oil Pressers,Plant Extract,Shellers

- Year Established

- 2014

- No. of Total Employees

- 501-1000

- Company introduction

-

Henan Institute Of Grain Machinery Manufacturing Co., Ltd. is established driven by the academy of Henan University of Technology.our company is specializing in the production of grain and oil machinery, agricultural and sideline machinery. Cooperating with Henan Mechanical Design and Research Institute and Henna University of Technology (Former Zhengzhou Grain College), Henan Institute Of Grain Machinery Manufacturing Co., Ltd. has carried out the research and application of oil machinery, food machinery, grain machinery, construction machinery, and feed machinery, etc.

The business involves food machinery, coarse grain machinery, small oil mill, grain and oil engineering design, equipment manufacture and installation, project contracting, technical services, new product development, and oil by-products deep processing, etc.

- Main Markets

-

Congo

Congo

Ethiopia

Ethiopia

Malawi

Malawi

Malaysia

Malaysia

Paraguay

Paraguay

Philippines

Philippines

Saudi Arabia

Saudi Arabia

South Africa

South Africa

Uganda

Uganda

Zambia

Zambia

- Main Product

China

China