Welded Austenitic Stainless Steel Tube for feed water

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Torich

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Stainless Steel

Torich International,.Ltd

- Verified Certificate

-

10

| Product name | Welded Austenitic Stainless Steel Tube for feed water | Certification | - |

|---|---|---|---|

| Category | Stainless Steel | Ingredients | - |

| Keyword | stainless steel tube , tubular , welded steel pipes , austenitic stainless steel tube | Unit Size | - |

| Brand name | Torich | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

ASTM A688 TP304/304L/304LN , TP316/316L/316LN Welded Austenitic Stainless Steel Feedwarter Heater Tubes

Size range:

O.D.: 4.0-230mm W.T.:1-30mm L: according to customer requirement

Material and Manufacture:

Tubes are made from Flat-rolled steel by automatic welding process.

Subsequent to welding and prior to final heat treatment, the tubes are cold drawn or cold rolled

The tubes are ready for U-bending after annealed, according to customer's drawing and design.

Suface Condition:

The tubes are pickled innitric and hydraofluoric acids.

Bright annealing.

Mechanical Requirement

Grade: | TP304 | TP304L | TP304LN | TP316 | TP316L | TP316LN | TP316LN | TPXM-29 | TP304N |

UNS | S30400 | S30403 | S30453 | S31600 | S31603 | S31653 | S31653 | S24000 | S30451 |

C, max | 0.08 | 0.035 | 0.035 | 0.080 | 0.035 | 0.035 | 0.035 | 0.08 | 0.080 |

Mn, max | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 11.5-14.5 | 2.00 |

P, max | 0.045 | 0.045 | 0.045 | 0.045 | 0.045 | 0.045 | 0.045 | 0.060 | 0.045 |

S, max | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 |

Si, max | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

Ni | 18.0-20.0 | 18.0-20.0 | 18.0-20.0 | 16.0-18.0 | 16.0-18.0 | 16.0-18.0 | 16.0-18.0 | 17.0-19.0 | 18.0-20.0 |

Cr | 8.0-11.0 | 8.0-13.0 | 8.0-12.0 | 11.0-14.0 | 10.0-14.0 | 11.0-14.0 | 11.0-14.0 | 2.3-3.7 | 8.0-18.0 |

Mo | … | … | … | 2.00-3.00 | 2.00-3.00 | 2.00-3.00 | 2.00-3.00 | … | … |

Nitrogen | … | … | … | … | … | … | … | … | … |

Copper | … | … | … | … | … |

|

|

|

|

| Grade: | TP316N | … | … | … | … |

| UNS | S31651 | N08367 | N08926 | S31254 | S32654 |

| C, max | 0.070 | 0.030 | 0.020 | 0.020 | 0.020 |

| Mn, max | 2.00 | 2.00 | 2.00 | 1.00 | 2.0-4.0 |

| P, max | 0.045 | 0.040 | 0.030 | 0.030 | 0.030 |

| S, max | 0.030 | 0.030 | 0.010 | 0.100 | 0.005 |

| Si, max | 4.8-6.0 | 1.00 | 0.50 | 0.80 | 0.50 |

| Ni | 9.58.0 | 20.0-22.0 | 24.0-26.0 | 19.5-20.5 | 21.0-23.0 |

| Cr | 19.0-22.0 | 23.5-25.5 | 19.0-21.0 | 17.5-18.5 | 24.0-25.0 |

| Mo | 0.30-1.50 | 6.0-7.0 | 6.0-7.0 | 6.0-6.5 | 7.0-8.0 |

| Nitrogen | … | … | … | … | 0.45-0.55 |

| Copper | … | … | … | 0.30-0.60 |

Tensil Requirements

| Grade and UNS | Tensile strength min ksi [Mpa] | Yield strength min ksi [Mpa] | Elongation in 2in or 50mm min % | ||||||

| 304, 316 S30400, S31600 | 75 [515] | 30 [205] | 35 | ||||||

| 304L, 316L S30403, S31603 | 70 [485] | 25 [175] | 35 | ||||||

| XM-29 S24000 | 100 [690] | 55 [380] | 35 | ||||||

| 304N, 316N S30451, S31651 | 80 [550] | 35 [240] | 20 | ||||||

| 304LN, 316LN S30453, S31653 | 75 [515] | 30 [205] | 35 | ||||||

| N08367 t≤0.187 | 100 [690] | 45 [310] | 30 | ||||||

| N08367 t>0.187 | 95 [655] | 45 [310] | 30 | ||||||

| N08926 | 94 [650] | 45 [310] | 35 | ||||||

| S31254 t≤0.187 | 100 [690] | 45 [310] | 35 | ||||||

| S21254 t>0.187 | 95 [655] | 45 [310] | 35 | ||||||

| S32654 | 120 [825] | 65 [450] | 40 | ||||||

Permissible Variations in Dimensions

Group | Size, | Permissible | Permissible in WT, % | PermisibleVariations in Cut Length, | |

1 | Up to 1/2(12.7), excl | ±0.005[0.13] | ±15 | 1/8[3] | 0 |

2 | 1/2 to 1 1/2(12.7 to 38.1 excl | ±0.005[0.13] | ±10 | 1/8[3] | 0 |

3 | 1 1/2 to 3 1/2(38.1 to 88.9 excl | ±0.010[0.25] | ±10 | 3/16[5] | 0 |

4 | 3 1/2 to 5 1/2(88.9 to 139.7 excl | ±0.015[0.38] | ±10 | 3/16[5] | 0 |

5 | 5 1/2 to 5 1/2(139.7 to 230.2 excl | ±0.030[0.76] | ±10 | 3/16[5] | 0 |

Reference Documents:

ASTM STANDARDS

ASTM A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

ASTM A480 / A480 M Specification for General Requirements for Flat-Rolled Stainless and Heat-

Resisting Steel Plate, Sheet and Strip,

ASTM A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys.

ASTM A1016/ A1016 M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy

Steels, and Stainless Steel Tubes.

ASTM E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

SAE J1086 Practice for Numbering Metals and Alloys (UNS)

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- sales

- Address

- Room706,Qiling Mansion, Yinzhou District, Ningbo,China 315100

- Product Category

- Steel Pipes

- No. of Total Employees

- 101-500

- Company introduction

-

Torich Interational Co.,Ltd is a professional manufacturer and exporter of steel pipes materials. It is an international marketing and sales company specialized in steel tubes, which holds the factories of Seamless Steel Tubes with Carbon and Alloy Steel Grade, Welded Precision Steel Tubes,DOM Steel Tubes, Seamless & Welded Stainless Steel Tubes with Nickel and Alloy Steel Grade.

Our factory was established since 1997, with the name of Haiyan Sanxin Steel Pipe Co., Ltd. The factories’ technicians are of great engineering experience in steel pipe industry for more than 20 years, which are in great command of production technology for Cold Drawing and Cold Rolling. So we have strong technician team and manufacturing capability.

- Main Product

Related Products

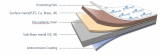

clad steel(Ecoteel)

Stainless Steel Double Ring Press Joint SP-JOINT

clad steel(Ecoteel)

Stainless Steel Sheet

Stainless Steel Coil

China

China