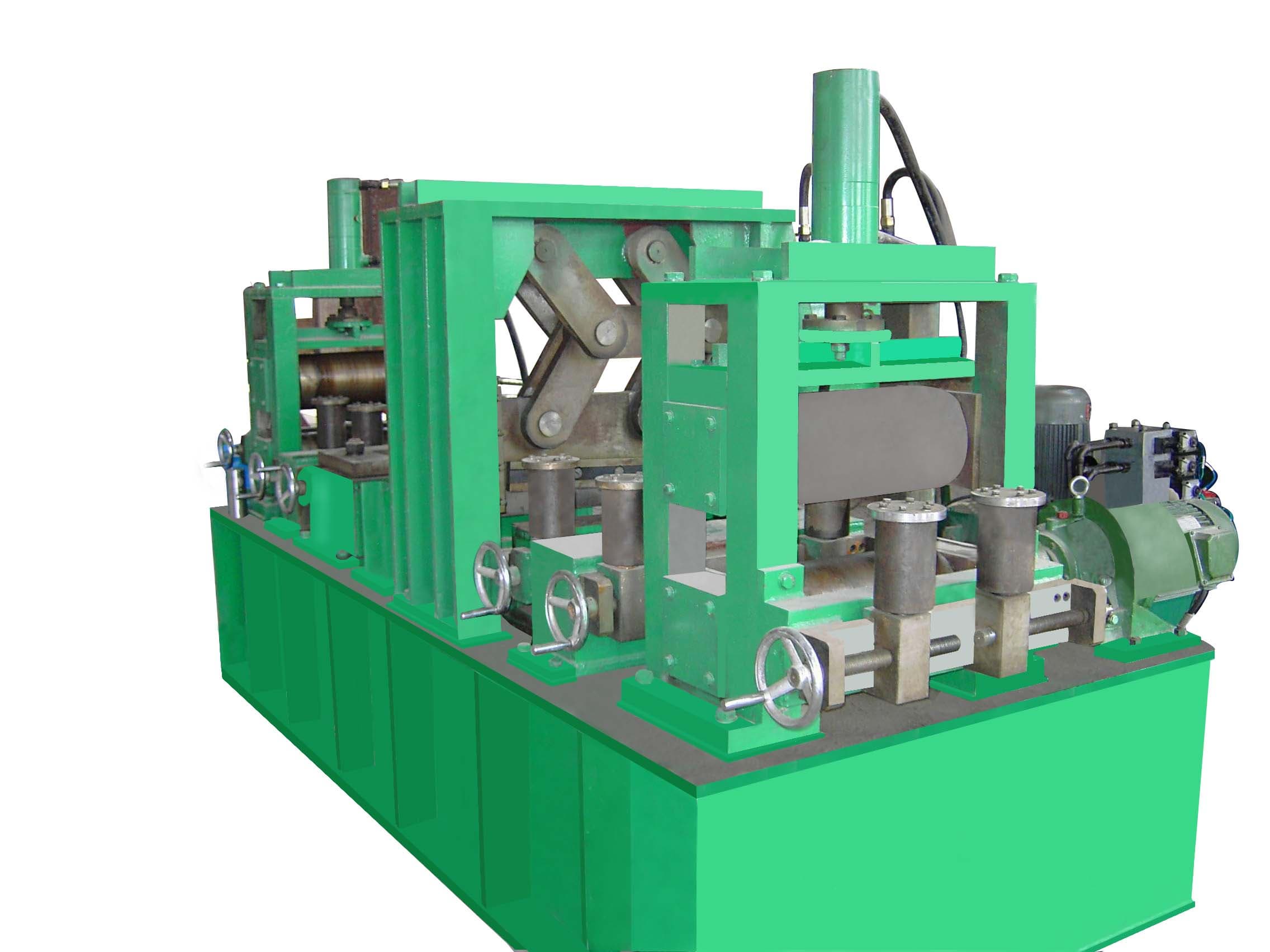

shear and welder for tube mill

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Allsteel

- Payment Terms

- L/C,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Welding Equipment

Shijiazhuang Allsteel Machinery Co.,ltd

- Verified Certificate

-

10

| Product name | shear and welder for tube mill | Certification | - |

|---|---|---|---|

| Category | Welding Equipment | Ingredients | - |

| Keyword | steel pipe welding machine , shear and welder , steel tube welder | Unit Size | - |

| Brand name | Allsteel | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Shear and welder for tube mill

Shear end welder plays an important role in a tube mill. Automatic shear and coil joining together.The shear blade and welding head are on the welding trolley. The head and tail of the coil, after cutting, are hold down and then automatic welding is carried out. The welding seam on the wall of the pipe forms spiral line, improve the rigidity of welding. Compared with other brand, the system has the simple structure, convenient operating, smart and fast seam alignment, and exact reliable action.

It consist of base, pinching device, alignment device, shear, travel system, welding mechanical system, hydraulic system, electronic control, welder, torch, wire feeding system, etc.

Shear end welder specification

|

Type |

Width(mm) |

Thickness(mm) |

Executive body |

welder |

|

φ50 |

40~200 |

0.8~3.0 |

pneumatic |

TIG |

|

φ76 |

100~260 |

0.8~3.5 |

pneumatic |

CO2 shield |

|

φ127 |

120~400 |

1.0~4.0 |

hydraulic | |

|

φ140 |

160~440 |

1.0~4.5 |

hydraulic | |

|

φ165 |

280~520 |

2.0~6.0 |

hydraulic | |

|

φ219 |

360~700 |

2.0~8.0 |

hydraulic | |

|

φ273 |

520~860 |

4.0~10.0 |

hydraulic | |

|

φ325 |

500~1020 |

4.0~12.0 |

hydraulic | |

|

φ426 |

600~1300 |

6.0~16.0 |

hydraulic | |

|

φ508 |

700~1650 |

6.0~18.0 |

hydraulic |

|

Type |

Width(mm) |

Thickness(mm) |

Executive body |

welder |

|

φ50 |

40~200 |

0.8~3.0 |

pneumatic |

TIG |

|

φ76 |

100~260 |

0.8~3.5 |

pneumatic |

CO2 shield |

|

φ127 |

120~400 |

1.0~4.0 |

hydraulic | |

|

φ140 |

160~440 |

1.0~4.5 |

hydraulic | |

|

φ165 |

280~520 |

2.0~6.0 |

hydraulic | |

|

φ219 |

360~700 |

2.0~8.0 |

hydraulic | |

|

φ273 |

520~860 |

4.0~10.0 |

hydraulic | |

|

φ325 |

500~1020 |

4.0~12.0 |

hydraulic | |

|

φ426 |

600~1300 |

6.0~16.0 |

hydraulic | |

|

φ508 |

700~1650 |

6.0~18.0 |

hydraulic |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T,Western Union | Shipping time | Negotiable |

- President

- Mr. Hui

- Address

- Economical and technological zone, Shijiazhuang, China

- Product Category

- Metal & Metallurgy Machinery

- Year Established

- 2008

- No. of Total Employees

- 101-500

- Company introduction

-

Shijiazhuang Allsteel Machinery Co.,Ltd located in Shijiazhuang is a leading High frequency carbon steel tube mill and slitting line manufacture, involved in designing, research and development, manufacture, sale, and after-sale service. With many years of experience in industry manufacture, Allsteel has domestic advanced R&D and design competence. From establishment, Allsteel is dedicated in industry of steel development, providing Professionalization, Personalization, Customization system solution for steel tube mill, cold forming machine, slitting line, cut to length line.

Allsteel tube mill lines are widely applied for furniture, automotive industry, mechanical tube, structural tube, water/gas tube, API for oil and natural gas, etc.

Allsteel wins more than 100 domestic and overseas production lines of the large-scale cold-formed, longitudinal welded pipes and slitting line with good reputation and quality. Our machines are exported to Thailand, Malaysia, South Africa, Brazil, Russia, Kazakhstan and so on.

- Factory Information

-

Shijiazhuang Allsteel Macchinery Co.,Ltd

- Main Product

China

China