Laser Welding Machine_LWI V Mobile Flexx

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Germany

- Brand name

- Vision Lasertechnik GmbH

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Industry Laser Equipment & Parts

Vision Industries Korea LLC.

- Verified Certificate

-

10

| Product name | Laser Welding Machine_LWI V Mobile Flexx | Certification | - |

|---|---|---|---|

| Category | Industry Laser Equipment & Parts | Ingredients | - |

| Keyword | laser welder , laser welding machine , laser welding system , laser welding equipment | Unit Size | 850.0 * 1200.0 * 900.0 mm |

| Brand name | Vision Lasertechnik GmbH | Unit Weigh | 410 kg |

| origin | Germany | Stock | - |

| Supply type | - | HS code | 851580 |

Product Information

LWI V Mobile-FLEXX - When flexibility counts

If you want to be prepared for everything, the Mobile Flexx should be with you. All functions included in our workstations as Unixx III or T-base are available here too. So you have full microprocessor control for all movements and the full synchronization of laser and movements.

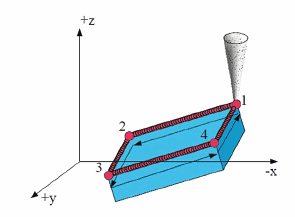

Even teach in, marking and 3-PCD are included in this unit. Equally to all of our workstations, the 4 axes can be upgraded to be used with a high precision rotation stage or even a wire feeder. Together with the strong platforn, the long distance motorized X axis allows for working on molds of size 2000 * 2000 mm.

So it doesn’t matter whether you work inside the shop on a table or outside on huge molds

– the Mobile Flexx will be the professional solution to get your job done.

Highlights

CAN-Step: The intelligent axis control

Precisely controls axis movements. This extends manual welding by its sophisticated automatic and programable functions. Touchscreen and Joystick terminals directly in your workspace provide a unique, simple control concept. Thanks to the completely integrated hardware, a separate computer is not needed.

PDS – Pulse Distance Synchronization

Enables the handling of complicated geometries in four axis without complex programming. A small number of support points are hit once on the contour of the work piece in advance. The user can subsequently move the programmed welding line forward and backward using the joystick and can also shift its position by offsetting the start point.

„Teach in“ programming

Enables the handling of complicated geometries in four axis without complex programming. A small number of support points are hit once on the contour of the work piece in advance. The user can subsequently move the programmed welding line forward and backward using the joystick and can also shift its position by offsetting the start point.

PCD – 3 Point Cycle Definition

You can process circular type contours by using the PCD function with the XY axis. The circular path is precisely defined through the teaching of only three support points. You do not need to know the center or the diameter; the position on the work piece is optional. You can move along the programmed course either forward or backward by using the joystick.

Combinable with a rotating device

Specially developed turning units increase the user value of your workstation. They incorporate all functions of CAN-Step control, available at the touch of a button, including pulse synchronization and „Teach in“ programming. Additional features: • Swivel-mounted • Free implementation up to Ø40 mm • different chuck types, chucking range up to Ø 160 mm.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- Ingeun Choi

- Address

- 22-1, Siheung-daero 935beon-gil, Siheung-si, Gyeonggi-do 14956, Korea

- Product Category

- Industry Laser Equipment & Parts

- Company introduction

-

Global Laser welding & marking machines

- Main Markets

-

Brazil

Brazil

Thailand

Thailand

Viet Nam

Viet Nam

- Main Product

Related Products

10W 20W 30W 50W Fiber laser marking machine

CO2 Laser Power Meter Probe 100 watts

ATONE Pro

13inch width laser die-cutting any-CUT III

Selriah Diode Laser

South Korea

South Korea