CAS 82834-16-0; Metal Passivator TH551,metal deactivator

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

Yantai Heng Nuo Chemical Technology Co.,Ltd

- Verified Certificate

-

10

| Product name | CAS 82834-16-0; Metal Passivator TH551,metal deactivator | Certification | - |

|---|---|---|---|

| Category |

Catalyst & Chemical Auxiliaries

Petrochemical Products |

Ingredients | - |

| Keyword | cas 82834-16-0 , metal passivator th551 , metal deactivator , benzotriazole derivative | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

CAS 82834-16-0; Perindopril TH551; Metal Passivator (Benzotriazole derivative)

1. Description

It has good anti-oxidation and copper corrosion inhibition. It is able to form the inactive film or create the chelate complex in combination with metallic ions to prevent metal oxidation.

2. Applications

It is used primarily for turbine oils, oil film bearing oils, industrial gear oils, transformer oils and circulation oils. It is forbidden to mix with ZDDP, otherwise the settling would occur.

3. The recommended dosage

from 0.03% to 0.1%.

4. Specification:

Item | Typical value | Test method |

Appearance | Brown transparent liquid | Eye inspection |

Density(20℃),kg/m3 | 910-1040 | GB/T2540 |

Motion Viscosity (100°C), mm2/s | 10-14 | GB/T265 |

Flash Point °C, | 130 min | GB/T3536 |

TBN, mg KOH/g | 210-230 | SH/T0251 |

Oxidation test (increment), | 90 min | SHT 0193 |

5. Packaging and storage

30L/package,200L/package

The requirements of SH/T0164 should be met during the storage, handling and blending.

The maximum temperature should not exceed 60°C . It is non-flammable, non-explosive, and non-corrosive. The precautions in safety, environment control, and application are the same

as those of common petroleum products, having no need of special protection

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- Mr Zhang

- Address

- No.32, Zhujiang Road, Kaifa District,Yantai,Shandong Province,China

- Product Category

- Catalyst & Chemical Auxiliaries,Chemical Product Agents,Other Inorganic Chemicals,Pharmaceutical Intermediates

- Company introduction

-

YanTai Heng Nuo Chemical Technology Co., Ltd.is a famous enterprise in China. Insisting on the independent innovation principle,we have developed almost 20 fine chemical products. Mainly include rubber ingredients, pharmaceutical intermediates and fine chemical products.With the leader of our enterprises spiritual of "Honesty, Disciplined, Ministrant and Innovative", We have kept a rapid growth in sales since 2011 and is establishing a good credit in rubber industry continually. Meanwhile,we are working closely with four domestic famous universities and scientific research institutions, developing the new and high technology with core competitiveness. Currently, we have made remarkable progress on the technological innovation and environmental protection.

Mainly include three series products of Special rubber additive, Lubricant additive, Pharmaceutical intermediates: 2,5-Dimercapto-1,3,4-Thiadiazole(DMTD), Thiadiazole derivatives, Chlorinated polyethylene, Thiadiazole Vulcanizing agent, TDDS of Chlorinated polyethylene vulcanizing agent, BF of vulcanization accelerator agent, 512A of CPE cross link agent, Metal passivator TH561, Orderless vulcanizing agent BIBP,Orderless DCP, Cross linking agent TAIC.

Adopts micro fine and nanotechnology, manufactures super fine nanometer products and improves their activities.

Transforms the technical and equipment to integrate the drying and grinding process,keeps raising the level of automatization and continuity of produce.

Takes the leading at home in applying the 5000-liter large scale reaction kettle synthetic rubber chemicals, increases per batch productions and raises the ratio of qualified product.

Perfects the three wastes treatment works, achieved the control of national standard and created a green production environment.

- Main Product

Related Products

Corn Cob Meal

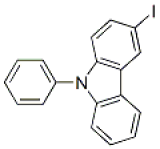

3-Iodo-N-phenylcarbazole, CAS NO.: 502161-03-7

C9 Petroleum Resin for Tire Rubber Compound softening oil

VCI Desiccant GVD310

Bisphenol-A(BPA)

China

China