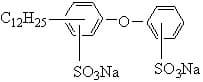

1. Per molecule both contain two negatively charged, that make it has better dispersing power. It has a higher solubility in the electrolyte solution. It is stability to acid, alkali and salt solutions.

2. Big molecular weight, high adsorption capacity, the preparation of emulsion aging is high efficient, low cost; latex particle size distribution is narrow and uniform.

3. Thermal stability is so excellent that it can still suitable for the emulsion polymerization reaction in the 80-120 ° C temperature conditions without losing the surfactant

4. Good mechanical stability. the emulsion, which emulsified by this product, even under high shear conditions, also showed remarkable stability.

5. Good oxidation stability at high temperature, only the strong oxidants can change it : when the temperature is 50℃, the strongest oxidants will play a role in a few hours later.

6. Less toxic in the concentration of 1%, contact with skin or eyes, it will only produce short-term pain and stimulate; but at higher concentrations (> 10%), to try to avoid contact with eyes or skin.

Purpose:

1. Emulsion polymerization

Styrene-butadiene rubber latex, ABS resin, acrylic resin, PVC, vinyl chloride, butyl benzoate, all above choose this product as emulsifier, enable the latex with small particle size, distribution, storage stability, gel, etc… and can use the dosage of the product to control emulsion particle size and surfactant.

2. Textile printing and dyeing, dyes, chemicals industry

1)Can be used as a homogenizing agent in acid dyeing of the nylon, acting as dyeing material carrier to control the transfer of the acid coloring matters, and make dye uniform distribution. The result is Reducing chromatism, dye material consumptions down, economic performance improved.

2)Often used as an additive compound component.

3)Commercialization additives of dye, Greatly enhance the dye dispersion, solubility index.

3. As a cleaning agent components

Also used as cleaning agent, wetting agent, coupling agent and stabilizing agent. It have synergistic effects with other non-ionic and anionic surfactants, can used as Low temperature soap, in general detergent, it also can dissolved and stable the Phenol in detergent formulations and the fungicides which conclude chlorophenol.

4. Oil industry

The High temperature stability and resistance to electrolytes of this product make it be used for Oleic acid emulsion in the third stage of the process of tertiary oil recovery. It used as emulsifier to isolate the acid sludge.

5. Phenolic resin industry

Used as binder and Link agent in water-solubility phenolic resin.

This resin is sensitive to temperature, and short shelf life, unless there is a refrigerated or frozen. If takes from small solution and to be used, there will has a good add water dilute force in resin application. Alkaline aqueous solution or alcohol solution used in traditional manufacturing as resin solvent, but to high molecular weight resin, the more alcohol or PH value are needed in order to maintain the stability of the resin in solution. This product can overcome these difficulties. It can dissolve high molecular weight resin, used in a wide PH range, strong dilution, long life, its advantages are follows: Reduce jet (frost) and curing. Add this product to do the accelerator; high molecular weight resin will reduce the volatilization loss. This product has no flash point and fire point, add the product can reduce the danger of fire. This product is excellent resin solvent, add 0.15% of this product can increase the water-soluble of high molecular weight resin, and increase ten-fold diluting capacity. In diluted solution, the resin containing the goods can be stored at room temperature for a month. Use this product to dissolve the resin can make full use of raw materials

, thereby reducing costs. Add this product can accelerate the cure speed of the high molecular weight resin.

6. Paint industry: used as the anionic leveling agent.

7. Pesticide industry: used as synergist, and spreading agent, wetting agent, penetrating agent and flowable in Pesticide emulsion.

8. Architectural industry: used as asphalt stabilizer which improve the road quality.

9. Production of thin films: used as antistatic agent in High polymer films

10. Electroplating industry: additive, Can control the shape and size of the grains.

11. Rubber industry: used as antistatic agent

12. Environmental protection: widely used in soil decontamination, subsurface repair and other geological aspects.

Packaging and storage: 125,240KG/ barrel. It can be packaged according to the request. The product is stability, Non-flammable, Non-explosive; It should be sealed airtight after using to prevent debris intrusion; Can adapt to the general ambient temperature (5~35%), avoid sun exposure, quality guarantee period is more than one year. To avoid the freeze happens. If frozen, it should be heated above 10℃, when liquefaction, using it after stirring.

Canada

Canada

China

China

India

India

Japan

Japan

U.S.A

U.S.A