Insulin syringe assembly machine

Assembly and printing machine for insulin syringes

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- MIAM

- Payment Terms

- L/C,T/T

- Production method

- Available

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- assembly machine, insulin syringe, insulin syringe assembly machine, insulin syringe assembly

- Category

- Other Machinery Parts

M-Tech Corp.

- Country / Year Established

-

South Korea

/

2001

South Korea

/

2001

- Business type

- Manufacturer

- Verified Certificate

-

10

| Product name | Insulin syringe assembly machine | Certification | CE |

|---|---|---|---|

| Category | Other Machinery Parts | Ingredients | - |

| Keyword | assembly machine , insulin syringe , insulin syringe assembly machine , insulin syringe assembly | Unit Size | - |

| Brand name | MIAM | Unit Weigh | - |

| origin | South Korea | Stock | 100 |

| Supply type | Available | HS code | - |

Product Information

Because of increase in adult disease, the number of diabetic is on the rise. In order to meet this market needs you need effective insulin syringe assembly line with high productivities.

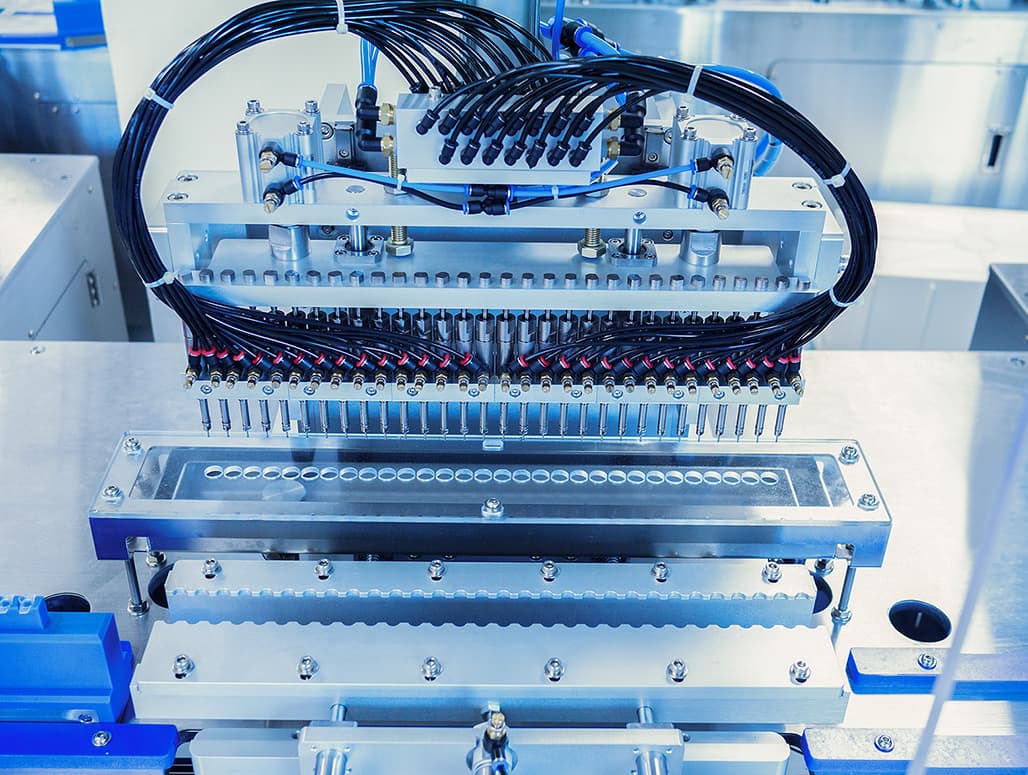

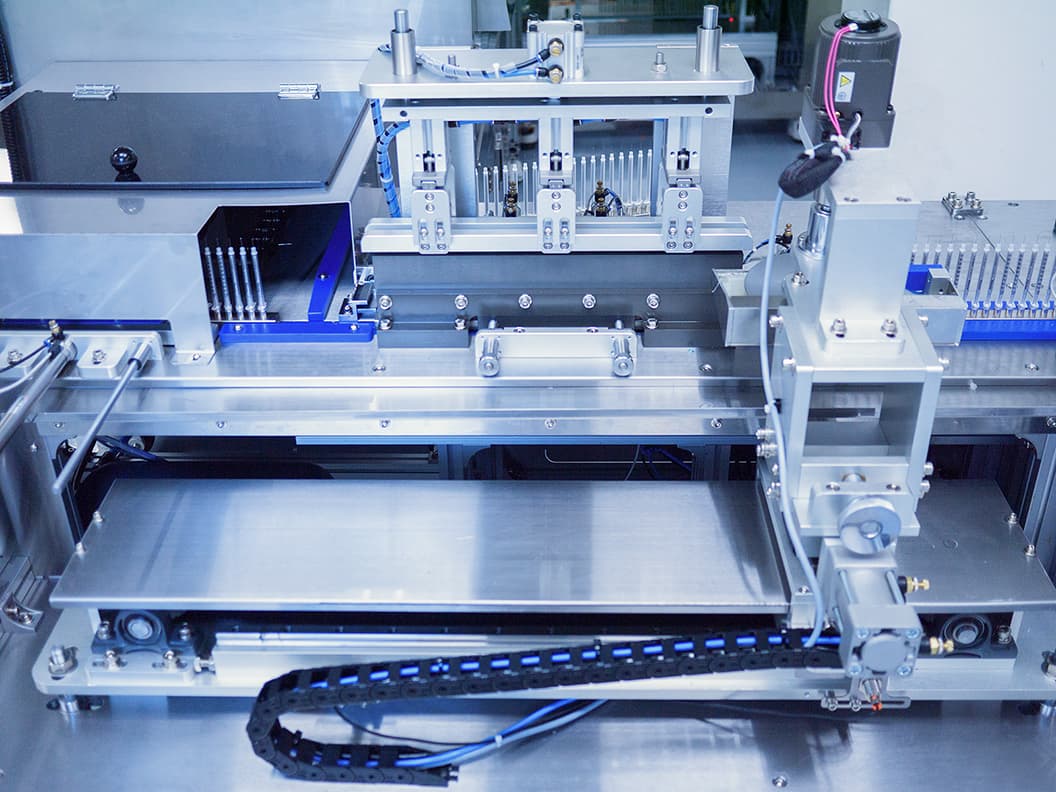

• Body frame : made with highest quality robust raw materials. Body frame is really important for durability and life span

• Standardized products : We use parts and products fromworld famous companies only. You can get the parts easily everywhere in the world.

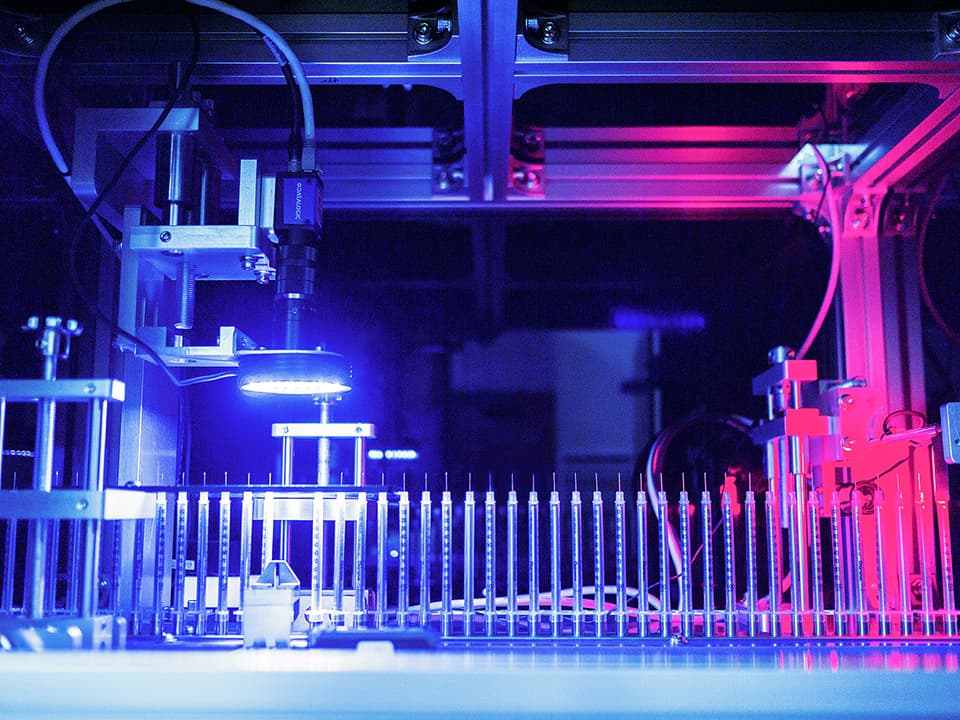

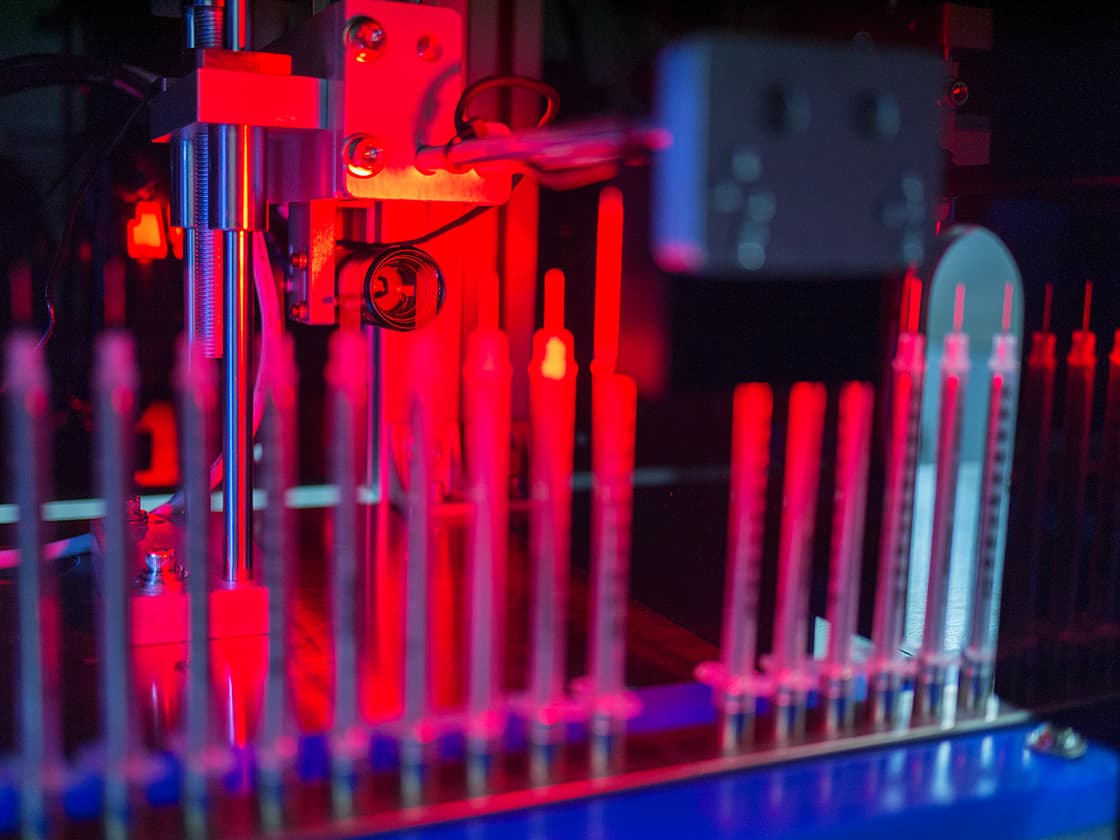

• Yield percentage : We boast high yield percentage. It is about 95% or more.

• 0.3ml : 15,000pcs/hour

• 0.5ml : 15,000pcs/hour

• 1ml : 15,000pcs/hour

* Productioncapacity depends on plastic parts qualities and operator’s technical skills.

How do they work?

Automatic insulin syringe line is combined assembly system of printing machine and assembly machine. Firstly barrels are supplied to the printing process. Secondly the barrels are assembled with cannulas and then they are passed though drying furnace and camera inspection zone. Lastly all the parts such as needle caps, plungers and plunger caps are assembled. On request we can add welding device at the connection part between needle caps and barrels to check whether it is a new one.

On request CE certificate is available.

* The best quality in Korea

* Made in Korea

* Contacct : M-Tech Corp.

* Webpage : www.m-tech2001.co.kr

* e-mail : sales at m-tech2001.co.kr

- Verified Certificate

-

B2B Trade

| Price (FOB) | Negotiable | transportation | Ocean Shipping |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Mr. DR Park

- Address

- Ojung-gu, Samjung-dong, 36-1, Bucheon Techno Ssangyong 3rd,B/D 101-1303, Dongnam-gu, Cheonan-si, Chungcheongnam-do, Korea

- Year Established

- 2001

- Company introduction

-

M-Tech has been established in 2001 in Korea and dedicated to theengineering and manufacturing production machines, molds for medical devices

such as normal syringes, Insulin syringes, pen needles and etc. Weare not only engineering company supplying production machine but also mold manufacturer.

M-Tech is a perfect solution provider for the following machinesfrom tubes for needle to packing for finished syringes.

- Raw materials such as Strips for SUS tube, SUS tubes for needles- Highquality molds (Highest quality molds at competitive prices)

- All the production machines for tubing line

- Needle assembly machine

- Automatic syringe assembly machine

- Automatic syringe printing machine

- Automatic syringe feeding machine

- Cannula production line

- Pen needle assembly machine

- Blood collection needle assembly machine

- Blood collection tube assembly machine

- Main Product

- Attached File

Related Products

JS-2EJ4

Electric ULV Sprayer ATOMER 2

Date Pin (Date Core)

Wrapping Scale machine

Diamond Tools: Diamond Blade, Diamond Polishing Pads, Diamond Grinding Wheel, Diamond Wire Saw