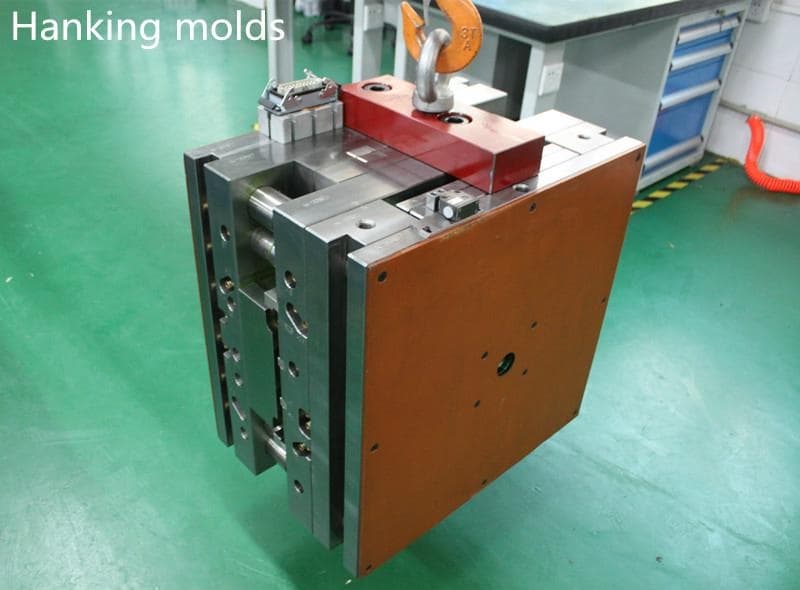

Injection Moulds for plastic parts

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Hanking

- Payment Terms

- L/C,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Molds

Hanking Plastic Manufactory(Shenzhen) Co.,Ltd

- Verified Certificate

-

10

| Product name | Injection Moulds for plastic parts | Certification | - |

|---|---|---|---|

| Category | Molds | Ingredients | - |

| Keyword | injection molds , plastic parts mould , oem injection molded design , china molds | Unit Size | - |

| Brand name | Hanking | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Injection moulds for plastic parts

1:Over 20 Years Professional Experience

2:International Standard Workshop

3:OEM Plastic Injection Mould

4:High -tech equipments to make moulds

5:You first choice

Mold specifications:

|

Mold Base: |

LKM, HASCO, DME, etc. |

|

Product Name: |

custom plastic mold, custom moulding custom injection molds |

|

Mold Cavity: |

Single, Mult, Family |

|

Molding Material: |

ABS, PC, PP, PE, PA, PS, +GF, POM, PMMA, ect. |

|

Color: |

transparent, solid color according to your requests |

|

Surface: |

textured, glossy or mirror polished, printing, planting

ect. |

|

Design software: |

PRO/E. Solidwork, UG. Moldflow. Autocad, etc |

|

Mold Material: |

S45C, P20, 718, 718H, 2738, 738H, NAK80, SKD61, E420,

etc. (for reference only) |

|

Mold Life: |

300,000~1,000,000cyces according to your requests |

|

Runner: |

Cold, hot runner such as YUDO. MASTER. SYNVENTIVE. etc. |

|

Lead time to T1 sample: |

3~5 weeks |

|

lead-time for production: |

1~2 weeks |

|

Quality: |

ISO 9001:2008,ISO14001:2004,TS16949:2009 |

|

Precision: |

0.005mm |

|

Service: |

OEM &ODM service. |

1.

We are a

professional manufacturer, we have our own injection factory, so the price will

be more competitive.

2.

Experienced

engineers, high precision injection machines and product

inspection equipment help us to provide timely and quality plastic mold and

product.

3.

Services available: prototypes making, 3D design for parts

and molds, tooling/mold making, polishing, volume production/molding, painting,

plating, surface texture, heat treating, IML/IMD, assemble, pack and ship

4.

OEM and

ODM orders are welcome.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T,Western Union | Shipping time | Negotiable |

- President

- Li Fung

- Address

- PingDong village, PingDi Town, LongGang District ,Shenzhen, China

- Company introduction

-

Established in 1996,Hanking Plastic Manufactory is a leading manufacturer of injection molding tools and plastic parts in Shenzhen city of China.

Hanking provides our clients with "One Stop Tooling and Manufacturing Service", To meet different clients' requirements, we also offer pad printing, silk-screen printing, painting, plating, final assembly and packaging service.

We own the advanced equipments for mold processed such as Swiss, Japan and Taiwan CNC, NC milling machine, WEDM, electric impulse etc to assure us supply the excellent and efficient mold and injection molded products. In addition, we can adopt the different hot runner systems such as Husky, Mold master, Sysventive, etc to meet the diverse requirements of our customers.

Our facilities is as below,

Mould making equipments: 34sets mould-making CNC/wire cutting/ EDM/ grinding/ drilling machines.

Injection molding equipments: 58sets injection press ( tonnage ranges from 90T to 650T) fitted with ROBOT ARM.

Secondary operation processing: CNC machining, ultrasonic welding, silkscreen/pad printing, oil spray, laser etching, electro-plating.

Assembly: 4 final assembly lines.

Hanking is proud of being an innovative company in mold design and efficient manufacturing processes. And we look forward to be your long term strategic partner.

- Main Product

China

China