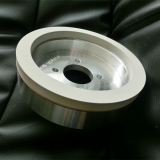

vitrified diamond grinding wheel for PCBN

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- MoreSuperHard

- Payment Terms

- MoneyGram,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Abrasive Tools

Henan More Superhard Products Co., Ltd (Skype:song.cocoa)

- Verified Certificate

-

11

| Product name | vitrified diamond grinding wheel for PCBN | Certification | - |

|---|---|---|---|

| Category | Abrasive Tools | Ingredients | - |

| Keyword | diamond , grinding , vitrified , wheel | Unit Size | - |

| Brand name | MoreSuperHard | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

vitrified diamond grinding wheels for polishing of PCBN

Description:

Vitrified bond grinding wheels have characteristics of sharp cutting, high efficiency, long life, less heat and blocking generated, easy control the precision and easy dressing.

Application of Vitrified bond grinding wheels:

Vitrified bond diamond grinding wheels: Mainly used for machining tungsten carbide, ceramic, cermets, optical glass, PCD, PCBN, CVD, natural diamond, stones and so on.

Vitrified bond CBN grinding wheels: Mainly used for machining cast iron, steel and so on.

vitrified bond diamond grinding wheel is popular used in natural diamond bruting, grinding and polishing, it can also be used in grinding PCD&PCBN blades, compared with resin bond wheel and metallic bond wheel, ceramic bond diamond wheel could process at least2 to 3 times produces under same at the same time, it do save customers' time and promote produce efficiency.

Type | D | W | T | H | X |

6A2 | 100 | 10 | 35 | 35 | 10 |

6A2 | 100 | 20 | 35 | 35 | 10 |

6A2 | 125 | 3 | 40 | 40 | 10 |

6A2 | 125 | 6 | 40 | 40 | 10 |

6A2 | 125 | 10 | 40 | 40 | 10 |

6A2 | 150 | 3 | 40 | 40 | 10 |

6A2 | 150 | 5 | 40 | 40 | 10 |

6A2 | 150 | 10 | 40 | 40 | 10 |

6A2 | 150 | 15 | 40 | 40 | 10 |

6A2 | 150 | 20 | 40 | 40 | 10 |

Application:

1, the first choice for mild steel, many years experience demonstrate that the CBN grinding wheel has the best efficiency , and improve efficiency by about 100%, and the economic benefit is increased by 200%.

2, used for big quantity produce on the CNC machine, for miniature bearing, air compressor, crankshaft camshaft, high precision and the fine grinding end milling.

3, for the workpiece which has a complicated surface, and request grinding wheel has good edges, pinion gear knife, pull the sword, high precision gears, modeling, punch, etc.

4, large precision workpiece (machine slideway, high precision ball screw, etc) fine grinding end mill. These workpiece use normal abrasive usually because the high temperature and easy to cause grinding large deformation, best choice is CBN grinding wheel.

5, for heat resistant steel and high hardness by (HRC55 above) alloy steel precision parts and fine grinding end mill. These parts to use general grinding wheel consumption of grinding or blunt and not too fast for a high precision

6, for special steel contains such as tungsten, molybdenum, vanadium containing high tungsten alloy steels, cobalt alloy steel, special high speed steel paper cutting knife, difficult to further processing of heat resistant steel of the super finishing, and other steel quenching of honing tool.

7, for high speed steel which has tungsten and Tungsten molybdenum, especially vanadium alloy steel, cobalt alloy steel special high speed steel paper cutting knife burrs .

8, for the stainless steel and high hardness HRC55 (more) made of alloy steel precision parts and fine grinding end mill. These parts to use common abrasive grinding excessive consumption of grinding and not too fast or blunt get high precision.

9, for titanium alloy CBN grinding, grinding emery wheel is the best choice

Features: |

1. Ceramic diamond wheel for PCD cutting tools, carbide cutting tools |

7. Increased feed rates |

8. Good shaped |

9. No dressing tools and less heat occurs to avoid burning the workpiece are just some of the advantages of our grinding wheels can provide for you. And the dynamic balance can achieve at G0.4 for our vitrified wheels. |

Any question you contact:

Cocoa Song

Skype ID:song.cocoa QQ:1730690554

Whatsapp:+8615138688501

Wechat:MORECocoa

Cell No.:0086-15138688501

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | MoneyGram,T/T,Western Union | Shipping time | Negotiable |

- President

- Jiaojie

- Address

- Room 906, Tower B, Wanda Plaza Office Building, No. 171 Zhongyuan Rd, Zhongyuan District, Zhengzhou , Henan, China

- Product Category

- Abrasive Tools

- Year Established

- 2014

- Company introduction

-

Henan More Super Hard Products Co., Ltd is one of the leading company expert in supplying various ultra hard products including synthetic diamond tools, Cubic Boron Nitride(CBN) tools, which is widely used in Petroleum & Geology Industry, Auto & Aviation Processing Industry, Electric Processing Industry, Natural Diamond & Jewelry Processing Industry.

The company's production and sales of products covered vitrified bond tools, resin bond tools, metal bond tools, electroplated diamond/CBN tools, Vacuum brazed products, CVD diamond tools, Polycrystalline Diamond (PCD) tools, Cubic Boron Nitride (CBN) tools.

Our objective is to meet all the customers’ needs and help every customer achieve maximum benefits.

More brings in revenue for you, you win, we win!

Our products are PCD Polycrystalline Diamond, TSP Polycrystalline Diamond, Big Size Synthetic Monocrystalline Diamond, CBN Inserts For Hardened Steel, Solid CBN tips, PCBN Cutting Tool Blanks, PCD Cutting Tool Blanks, PDC Cutter, PCD Tool Grinder, PCD Inserts, PCBN Inserts, CVD Diamond Tools, CBN Grinding Wheel, PCD end mills, PCD diamond drill & core bits, PDC bits, Diamond dressers, Solid ceramic inserts, Special Tools for Auto Engine Machining, PCD Engraving Tools, Roller cutting tools, PCD/PCBN Grooving Tools, PCD reamers, Electroplated Diamond Grinding Wheels, Electroplated Diamond Grinding Discs, Grinding & Cutting Blades, Electroplated Diamond Cutting Discs, Diamond Cutting & Grinding Disc, Diamond Cup Wheel, PDC Bits, PCD Cup Wheel, Vitrified diamond/CBN wheels, resin diamond cutting discs, Resin Diamond/CBN grinding wheels, Metal bond diamond cutting discs and grinding wheels.

- Main Product

Related Products

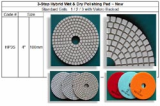

3 Step Hybrid Wet Dry Polishing Pad

Sun Turbo Cutter

ADAS Turbo Laser Welded Saw Blade

Abrasive wheel

Grinding Block

China

China