High Efficiency Magnetic Separator

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- FTM

- Payment Terms

- D/A,D/P,L/C,MoneyGram,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- magnetic separator, permanent magnetic separator, magnetic drum separator, wet magnetic separator

- Category

- Mining Machinery

Henan Fote Heavy Machinery Co., Ltd.

- Verified Certificate

-

10

| Product name | High Efficiency Magnetic Separator | Certification | - |

|---|---|---|---|

| Category | Mining Machinery | Ingredients | - |

| Keyword | magnetic separator , permanent magnetic separator , magnetic drum separator , wet magnetic separator | Unit Size | - |

| Brand name | FTM | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Magnetic Separator Application

Magnetic Separator is mainly used for cleaning, and especially suitable for the minerals with particle size less than 0.15mm. The magnetic separator is also suitable for processing fine, weakly magnetic minerals, such as hematite, limonite, ilmenite, manganese, wolframite, tantalum-niobium, and etc. It is also suitable for removing iron and titanium from non-metallic minerals such as quartz, feldspar, nepheline, fluorite, ceramic material, and etc.

Brief Introduction of Magnetic Separator

The magnetic separator utilizes the combined force field of magnetism , pulsating fluid and gravity to continuously beneficiate fine weakly magnetic minerals . It is equipped with unique pulsating mechannism and possesses the advantages of large beneficiation ratio , high recovery , and a matrix that does not easily clog.

Magnetic Separator Working Principle

Slurry is fed into cavity from the bottom of drum, and the magnetic ores fall into concentrate tank after reaching a certain height, while the non magnetic ores will enter into tailings tank along with slurry in the opposite direction with drum.

Magnetic Separator Feature

• Our machine uses vertical swivel rotation mode , So for each set of magnetic media , rinse ore concentrate direction is opposite with to the mine direction . Then Coarse particles can be washed out and needn't to pass through the magnetic media heap , thereby preventing the clogging of the magnetic medium.

• Our machine set ore pulp pulsating bodies , driver ore pulp generated pulsatile flow forces .Under the effect of the pulsating flow forces , The mineral particles in the ore pulp is always in a loose state, Then can improve the quality of magnetic concentrate .

• Our machine use special magnetic system structure and portfolio optimization magnetic media , so our machine ore size can up to 2mm , simplifies field grading operations and can be used widely

• The scavenging area is shorter than counter-current tank and the dewatering area is longer than fair current tank. Therefore, it has high recovery rate and concentrate grade.

• With a long scavenging area, and the high recovery rate and low grade tailings can be obtained even the capacity is large.

• Dewatering area is short.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,MoneyGram,T/T,Western Union | Shipping time | Negotiable |

- President

- Yang Fanglou

- Address

- High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China.

- Company introduction

-

Henan Fote Heavy Machinery Co., Ltd., the original Henan First Machinery Manufacturing Company, founded in 1982, is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing. Fote occupies an area of 360,000 square meters, including 60,000 square meters of standard heavy industrial workshops equipped with more than 500 large and medium-sized metal processing, riveting and assembly equipment. The total online staff is up to 2,000.

Henan Fote Heavy Machinery Co., Ltd. is a large-scale and professional manufacturer of mining machinery and general machinery, with two professional industrial workshops and more than 300 piece of machining, welding and assembly equipment of large and medium size. Fote Machinery has won wide praise at home and abroad by the exquisite techniques and advanced technologies, and it has also become the large mining machinery export base in China. The main products of our company include sand and stone equipment, ore beneficiation equipment, powder grinding equipment, asbestos equipment, compound fertilizer equipment, drying equipment, granulation machine, briquette machine and calcium silicate board machine, copper recycling machine, metal crushing machine and double-disk friction screw press machine.

- Main Product

Related Products

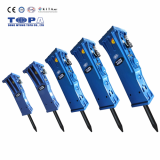

Hydraulic Breaker

Used crawler drill JUNJIN JD-800

Furukawa 322D Leg Drill and Support Leg

Rock Drill Spare Parts

Waste, Cement, Lime Rotary Kiln with capacity 50-800TPH

China

China