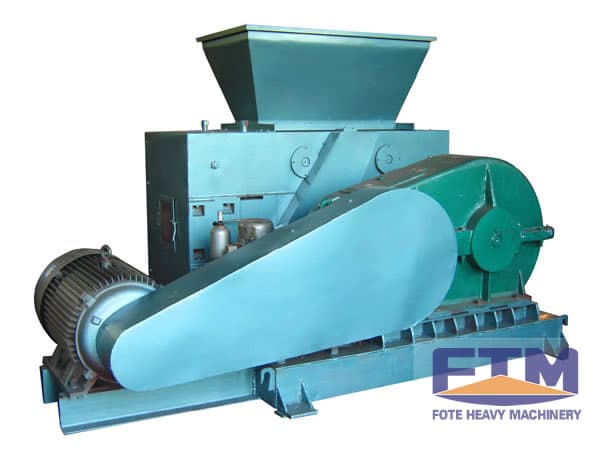

Metal Powder Briquetting Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- fote

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- briquette plant, briquette press machine, briquette making machine, briquetting press machine

- Category

- Mining Machinery

Henan Fote Heavy Machinery Co., Ltd.

- Verified Certificate

-

11

| Product name | Metal Powder Briquetting Machine | Certification | - |

|---|---|---|---|

| Category | Mining Machinery | Ingredients | - |

| Keyword | briquette plant , briquette press machine , briquette making machine , briquetting press machine | Unit Size | - |

| Brand name | fote | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Metal powder briquetting machine can press oxidize iron, dust, ash, blast furnace slag, manganese ore powder, silicon manganese alloy powder, iron smelting slag, ore concentrate and various ore powder materials in nonferrous metal industry into balls. So it is also called nonferrous metals briquetting machine.

Usage of Metal Powder Briquetting Machine:

Metal powder briquetting machine can be used to suppress coal powder, iron powder, coke coal, aluminum powder, iron scrap, iron oxide sheet, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke as well as other powder materials and waste residue. It is widely used in power plants, metallurgy, refractory material, chemical industry, energy, transport, heating and other industries. The processed material is energy saving, environmental protection and convenient for transportation, which improves the utilization rate of waste materials.

Working Principle of Metal Powder Briquetting Machine:

Metal Powder Briquetting Machine is mainly composed of three parts: feeding part, transmission part and molding part.

1. Feeding part. It ensures that the uniform material can enter into the roller by quantitative feeding. The screw feeding device is driven by electromagnetic motor, belt wheel and reducer, and then the materials will be pressed into the feeding inlet. Due to the torque characteristics of electromagnetic adjustable motor, when the pressing material amount of screw feeder is equal to the material needing amount of the host, it can maintain the constant feeding pressure to make the ball quality stable.

2. Transmission part. The main transmission system is motor - triangle belt - reducer - open gear - roll. The host is powered by the electromagnetic adjustable motor. The power is transferred to the drive shaft through belt pulley and cylindrical gear reducer by pin coupling. The driving shaft and driven shaft are in synchronous operation through the open gear.

3. Molding part: mainly refers to the main engine, and the core part is the roller.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- yangfanglou

- Address

- High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China

- Product Category

- Mining Machinery

- Year Established

- 1982

- No. of Total Employees

- 501-1000

- Company introduction

-

Henan Fote Heavy Machinery Co., Ltd., the former Henan First Machinery Factory, founded in Henan Zhengzhou- China machinery manufacturing capital in 1982, is a large joint-stock company specialized in manufacturing heavy mining machinery and civilian machinery; it has six production bases with an area of 240,000 m², more than 2000 existing employees, 160,000 m² standardized heavy industrial plant, and about 500 sets of big and medium sized processing, riveting, welding and assembly equipment. After 30-year construction and development, Fote has become famous production and export base of mining machinery and civilian machinery in China.

Making technical innovation as core strategy, Fote has established Beneficiation Machinery Research Institute, Crushing Machinery Research Institute, Powder-grinding Machine Research Institute and Building Materials Equipment Research Institute; as well, we have established good relationships with Harbin University, Tsinghua University, Zhejiang University and a number of well-known domestic universities to achieve resource sharing and complementary advantages, and speed up the transformation of scientific and technological achievements.

After long-term technology research and international exchange, qualities and technology contents of Fote products have achieved international top level and received wide recognition and praise in the international market; Fote products are exported to more than 90 countries and regions such as the United States, Russia, Kazakhstan, Turkey, Iran, South Africa, Ethiopia, Egypt, Viet Nam, Malaysia, India, Australia, Korea, Chile,etc.

Being customer-oriented, Fote is committed to providing the best solutions and turn-key projects for global customers; and relying on new advanced customer service platform, we provide customers with comprehensive, complete and 24-hour one-stop services.

Fote immutably ranks customers first and credit foremost. We are looking forward to achieving a win-win situation with you by first-class technology, first-class products and first-class service !

- Main Markets

-

Algeria

Algeria

Armenia

Armenia

Bahrain

Bahrain

Iran

Iran

- Main Product

China

China

_2.jpg)