High Hardness/Zirconia Ceramic Pump Components/INNOVACERA

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- INNOVACERA

- Payment Terms

- L/C,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Ceramics

Innovacera Advanced CO.,ltd

- Verified Certificate

-

11

| Product name | High Hardness/Zirconia Ceramic Pump Components/INNOVACERA | Certification | - |

|---|---|---|---|

| Category | Ceramics | Ingredients | - |

| Keyword | zirconia pump rod , zirconia pump shaft , zirconia pump components | Unit Size | - |

| Brand name | INNOVACERA | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | 8547100000 |

Product Information

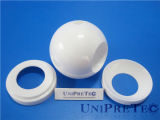

High Hardness/Zirconia Ceramic Pump Components/INNOVACERA

INNOVACERA's High Wear Resistant Pump Components include pistons, plungers, wear plates, bushes, liners and sleeves and mechanical and chemical seal rings.

For use in pump systems, zirconia ceramic components must be able to withstand punishing demands. Ceramics components leave no options for wear or corrosion, even with long downtimes and operating times.

Zirconia ceramic components have following features:

- High fracture toughness

- Thermal expansion similar to cast iron

- Extremely high bending strength and tensile strength

- High resistance to wear and to corrosion

- Low thermal conductivity

- Pressing

- Extrusion

- Isostatic pressing

- Injection moulding

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T,Western Union | Shipping time | Negotiable |

- President

- lalal

- Address

- Unit 4G,West Side,Lianchang bldg,No.6-8 Huli Avenue,Huli District,Xiamen,Fujian,China,361004

- Product Category

- Ball Bearings

- No. of Total Employees

- 1-50

- Company introduction

-

Innovacera offers a full range of solutions for supporting parts during sintering in reducing or oxidizing atmospheres up to 1800ºC. Innovacera has the industry's broadest range of manufacturing methods - including vacuum forming, casting, pressing and CNC machining. Mullite, alumina and alumina-zirconia compositions are available for applications in sintering of technical ceramic, electronic ceramic, and powder metal parts.

- Main Product

China

China