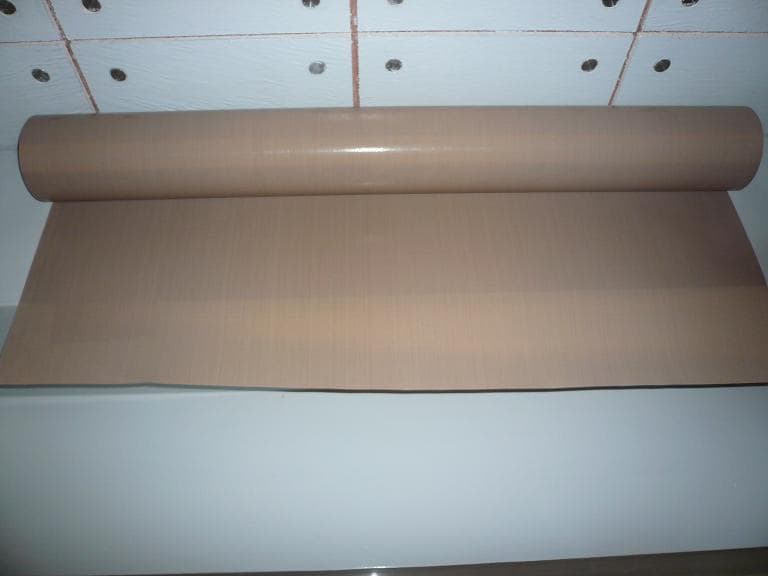

PTFE (teflon) coated fiberglass fabric

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- RUIDA

- Payment Terms

- L/C,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Fiberglass Cloth

JIANGSU RUIDA ELECTRONIC MATERIALS CO.,LTD

- Verified Certificate

-

10

| Product name | PTFE (teflon) coated fiberglass fabric | Certification | - |

|---|---|---|---|

| Category | Fiberglass Cloth | Ingredients | - |

| Keyword | ptfe coated fiberglass fabric , ptfe fabric , teflon coated fabric , teflon fabric | Unit Size | - |

| Brand name | RUIDA | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | 3920 |

Product Information

fiberglass fabric use best imported Fiberglass yarn as the weaving material to plain knit or specially knit into superior fiberglass basic cloth, coat it with fine PTFE(Teflon) resin then make it into various PTFE(Teflon) fabric in different thickness and widths.

Ruida PTFE Fabric Characteristic :

Generally, PTFE coated fiberglass fabric exhibits the following high-performance characteristics:

Non-stick surface

Excellent temperature resistance: from -100°F - +500°F (-73°C - +260°C)

Chemically inert

High tensile strength

Ruida PTFE Fabric Application:

Designed for a wide range of applications,Ruida PTFE fabric is available in several grades to match specific performance requirements.

Ruida Porous Bleeder & Filter PTFE Fabrics

These fabrics are available over a wide range of porosity. Principle applications include:

filtration

strainers

pollution abatement

Ruida Crease & Tear Resistant PTFE Fabric

Provides an unusually flexible material for use in applications where high tear-strength and good flex-life are demanded.

Ruida Anti-static PTFE Fabrics

Ruida black Anti-static PTFE fabrics is provided with a carbon loading giving semi-conductive and anti-static properties to the material. It eliminates or reduces static problems in belt and slip sheet applications.

Specification details:

| Part Number | Overall Thickness (inches) | Coated Weight (lbs/yd2) | Tensile Strength Warp/Fill (lbs/in) | TearStrength Warp/Fill (lbs) | Max.Width(mm) | ||

| Premium Grade | |||||||

| 9039 | 0.0029 | 0.27 | 95/55 | 1.5/0.9 | 3200 | ||

| 9012 | 0.0049 | 0.49 | 150/130 | 2.5/2.0 | 1250 | ||

| 9015 | 0.006 | 0.6 | 150/115 | 2.1/1.8 | 1250 | ||

| 9025 | 0.0099 | 1.01 | 325/235 | 7.5/4.0 | 2800 | ||

| 9028AP | 0.011 | 1.08 | 320/230 | 5.4/3.6 | 2800 | ||

| 9045 | 0.0148 | 1.45 | 350/210 | 5.6/5.1 | 3200 | ||

| Standard Grade | |||||||

| 9007AJ | 0.0028 | 0.25 | 90/50 | 1.7/0.9 | 1250 | ||

| 9010AJ | 0.004 | 0.37 | 140/65 | 2.6/0.7 | 1250 | ||

| 9011AJ | 0.0046 | 0.46 | 145/125 | 3.0/2.2 | 1250 | ||

| 9014 | 0.0055 | 0.54 | 150/140 | 2.0/1.5 | 1250 | ||

| 9023AJ | 0.0092 | 0.94 | 250/155 | 4.9/3.0 | 2800 | ||

| 9035 | 0.0139 | 1.36 | 440/250 | 7.0/6.0 | 3200 | ||

| 9065 | 0.0259 | 1.76 | 420/510 | 15.0/8.0 | 4000 | ||

| Mechanical Grade | |||||||

| 9007A | 0.0026 | 0.2 | 80/65 | 2.3/1.0 | 1250 | ||

| 9010A | 0.004 | 0.37 | 145/135 | 2.3/1.6 | 1250 | ||

| 9021 | 0.0083 | 0.8 | 275/190 | 8.0/3.0 | 1250 | ||

| 9030 | 0.0119 | 1.14 | 375/315 | 7.0/6.0 | 2800 | ||

| Economy Grade | |||||||

| 9007 | 0.0026 | 0.17 | 70/60 | 2.9/0.8 | 1250 | ||

| 9010 | 0.004 | 0.36 | 135/115 | 3.0/2.7 | 1250 | ||

| 9023 | 0.0092 | 0.72 | 225/190 | 4.4/3.2 | 2800 | ||

| 9018 | 0.0074 | 0.7 | 270/200 | 8.0/4.0 | 1250 | ||

| 9028 | 0.0112 | 0.98 | 350/300 | 15.0/11.0 | 3200 | ||

| 9056 | 0.0222 | 1.34 | 320/250 | 50.0/40.0 | 4000 | ||

| 9090 | 0.0357 | 2.04 | 540/320 | 10.8/23.0 | 4000 | ||

| Porous Bleeder & Filter | |||||||

| 9006 | 0.0025 | 0.12 | 40/30 | 5.3/4.0 | 1250 | ||

| 9034 | 0.0135 | 0.77 | 175/155 | 21.0/12.0 | 3200 | ||

| Crease & Tear Resistant | |||||||

| 9008 | 0.0032 | 0.31 | 90/50 | 1.6/0.5 | 1250 | ||

| 9011 | 0.0046 | 0.46 | 125/130 | 4.1/3.7 | 1250 | ||

| 9014 | 0.0056 | 0.52 | 160/130 | 5.0/3.0 | 1250 | ||

| 9066 | 0.0261 | 1.8 | 450/430 | 50.0/90.0 | 4000 | ||

| TAC-BLACK™ (Available anti-static) | |||||||

| 9013 | 0.0048 | 0.45 | 170/140 | 2.2/1.8 | 1250 | ||

| 9014 | 0.0057 | 0.55 | 150/120 | 1.7/1.4 | 1250 | ||

| 9024 | 0.0095 | 0.92 | 230/190 | 4.0/3.0 | 2800 | ||

| 9024AS | 0.0095 | 0.92 | 230/190 | 4.0/3.0 | 2800 | ||

| 9037AS | 0.0146 | 1.39 | 405/270 | 8.5/7.2 | 3500 | ||

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T,Western Union | Shipping time | Negotiable |

- President

- YANG ZONG

- Address

- 9#Zhongyang Road,Xuanbao Industtry Park,Taixing

- Product Category

- Adhesive Tapes & Papers,BBQ,Conveyors,Other Textiles

- Year Established

- 2012

- No. of Total Employees

- 51-100

- Company introduction

-

Jiangsu Ruida Electronic Materials Co., Ltd,covering an area of 3000 square meters,is located in Taixing, Jiangsu province, the Teflon Industry Cluster region,Which is 1 hour by express train from Shanghai. Affiliated to Veik Technology,our company is a professional manufacturer, committing to finishing and coating of advanced fabrics like Glass, Kevlar, Nomex with fluoropolymers.

The main series of our products are: PTFE coated fiberglass fabric, PTFE open mesh belts, PTFE adhesive tapes, PTFE fusing belts & seamless belts, PTFE coated Kevlar fabric & mesh, Silicone coated fiberglass fabric etc.

Our engineers conduct research and development activities regularly and gives emphasis to the development of ways to manufacture more efficiently which help reduce costs, improve quality and match individual requirements.

With help of advanced machinery and equipment from weaving, dipping to coating and further processing, together with our coating expertise and fabrication experience, Ruida designs, manufactures and markets PTFE and silicone-coated fabrics and belting, along with an extensive line of pressure sensitive tapes for use in diverse industrial applications worldwide. Ruida has invested in a fully automated German Karl Mayer high speed warping machine running at 1000 meters per minute,and 8 Dornier wide rapier looms,with a breadth of 4300mm. Could be brought up to 10 times the current and usual, whilst our fabrics tensile strength has increased by almost 80%. Obvious improvements were observed in our products’cleanliness,dimentional stability,density,abrasion resistance,even thickness&correct weight and exceptional product specifications above all other domestic productions.

We like to meet critical customers who encourage us to work more perfectly, to be more creative. We are always ready to make more value for you. Welcome for business discussion, cooperation or just technical exchange.

- Main Markets

-

Canada

Canada

Egypt

Egypt

Greece

Greece

India

India

U.S.A

U.S.A

- Main Product

Related Products

Alu Coated Glass Fiber Needle Mat for thermal insulation

3mm Fiberglass textured cloth

Resistance UV radiation PTFE coated fiberglass yarn roving

FRP cross flow fan

Glass Fiber Cloth

China

China