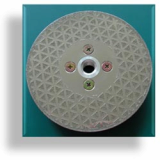

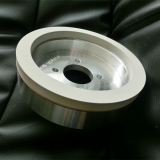

cup-shaped vitrified diamond grinding wheel

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- MoreSuperHard

- Payment Terms

- MoneyGram,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Abrasive Tools

Henan More Superhard Products Co., Ltd (Skype:song.cocoa)

- Verified Certificate

-

11

| Product name | cup-shaped vitrified diamond grinding wheel | Certification | - |

|---|---|---|---|

| Category | Abrasive Tools | Ingredients | - |

| Keyword | vitrified diamond grinding wheel , cup-shaped | Unit Size | - |

| Brand name | MoreSuperHard | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Vitrified Bond Wheels

Vitrified bond is a vitreous binding material and generally contains pores inside while other materials contain no pores. Therefore vitrified bond wheels have excellent grinding ability and are superior in forming.

(1) Characteristics of Vitrified Bond Wheels

1.Wheelgrinding ability and wheel life depend on the combination of binding material, super abrasive mesh size, concentration, and porosity. The harder the bond, the longer wheel life is achieved.

On the contrary, the softer the bond, better grinding ability is achieved because porosity becomes higher. Also higher concentration of abrasive, equates to longer wheel life.

2.Automated processing is available because simultaneous operation of truing and dressing using rotary dresser on the grinding machine is possible.

3.Cutting edges can be manipulated in such a manner that the surface finish of the part can be controlled.

4.Diamond wheels have difficulty in truing and dressing with rotary dressers. Therefore surface finish depends on the mesh size of super abrasive in the diamond wheel.

(2) Application of Diamond wheels

1.They are efficiency used for grinding difficult-to-machine materials such as PCD, PCBN, ceramics, etc.

2.They are generally superior in grinding ability to metal bond wheels. Because the vitrified bond has no elasticity, it is better suited for tight tolerance applications than resin bond wheels.

(3) Application of CBN Wheels

1.They are used for grinding ferrous materials such as automotive parts(camshafts, crankshafts, gears, CVJ, etc.), bearing parts, household appliance parts(compressors, motor shafts, etc,), and cutting tools.

2.CBN abrasive has superior heat stability thus providing excellent performance in super high-speed grinding to process camshafts, crankshafts, etc.

Type | D | T | H | W | X |

6A2 | 100 | 35 | 20 | 10 | 10 |

6A2 | 100 | 35 | 20 | 20 | 10 |

6A2 | 125 | 40 | 32 | 3 | 10 |

6A2 | 125 | 40 | 32 | 6 | 10 |

6A2 | 125 | 40 | 32 | 10 | 10 |

6A2 | 150 | 40 | 40 | 3 | 10 |

6A2 | 150 | 40 | 40 | 5 | 10 |

6A2 | 150 | 40 | 40 | 10 | 10 |

6A2 | 150 | 40 | 40 | 15 | 10 |

6A2 | 150 | 40 | 40 | 20 | 10 |

6A2 | 155 | 40 | 40 | 10 | 10 |

6A2 | 220 | 50 | 75 | 20 | 10 |

Features: |

---Sharp cutting |

---High efficiency |

---Less heat and jam generated in grinding |

---easy control of the precision and easy dressing |

---High stock removal |

---Superior Edge Quality |

---excellent cutting edges |

---Increased Production Rates |

---long life performance |

---reduced cycle times |

---High polishing efficiency |

---long life |

--- superior finish |

Application: |

---mainly for diamond cutter (PCD) |

---hard alloy |

---optical glass |

---semiconductor materials |

---magnetic material |

---crystal |

---gemstone |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | MoneyGram,T/T,Western Union | Shipping time | Negotiable |

- President

- Jiaojie

- Address

- Room 906, Tower B, Wanda Plaza Office Building, No. 171 Zhongyuan Rd, Zhongyuan District, Zhengzhou , Henan, China

- Product Category

- Abrasive Tools

- Year Established

- 2014

- Company introduction

-

Henan More Super Hard Products Co., Ltd is one of the leading company expert in supplying various ultra hard products including synthetic diamond tools, Cubic Boron Nitride(CBN) tools, which is widely used in Petroleum & Geology Industry, Auto & Aviation Processing Industry, Electric Processing Industry, Natural Diamond & Jewelry Processing Industry.

The company's production and sales of products covered vitrified bond tools, resin bond tools, metal bond tools, electroplated diamond/CBN tools, Vacuum brazed products, CVD diamond tools, Polycrystalline Diamond (PCD) tools, Cubic Boron Nitride (CBN) tools.

Our objective is to meet all the customers’ needs and help every customer achieve maximum benefits.

More brings in revenue for you, you win, we win!

Our products are PCD Polycrystalline Diamond, TSP Polycrystalline Diamond, Big Size Synthetic Monocrystalline Diamond, CBN Inserts For Hardened Steel, Solid CBN tips, PCBN Cutting Tool Blanks, PCD Cutting Tool Blanks, PDC Cutter, PCD Tool Grinder, PCD Inserts, PCBN Inserts, CVD Diamond Tools, CBN Grinding Wheel, PCD end mills, PCD diamond drill & core bits, PDC bits, Diamond dressers, Solid ceramic inserts, Special Tools for Auto Engine Machining, PCD Engraving Tools, Roller cutting tools, PCD/PCBN Grooving Tools, PCD reamers, Electroplated Diamond Grinding Wheels, Electroplated Diamond Grinding Discs, Grinding & Cutting Blades, Electroplated Diamond Cutting Discs, Diamond Cutting & Grinding Disc, Diamond Cup Wheel, PDC Bits, PCD Cup Wheel, Vitrified diamond/CBN wheels, resin diamond cutting discs, Resin Diamond/CBN grinding wheels, Metal bond diamond cutting discs and grinding wheels.

- Main Product

China

China

_2.png)