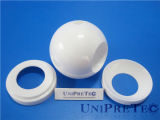

Gas Pressure Sintered/circular si3N4 ring

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- INNOVACERA

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Ceramics

Innovacera Advanced CO.,ltd

- Verified Certificate

-

11

| Product name | Gas Pressure Sintered/circular si3N4 ring | Certification | - |

|---|---|---|---|

| Category | Ceramics | Ingredients | - |

| Keyword | si3n4 ceramic ring , circular si3n4 ring , gas pressure sintered ceramic , si3n4 wearing ring | Unit Size | - |

| Brand name | INNOVACERA | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Typical circular si3N4 insulating ring features include:

- High strength over a wide temperature range

- High fracture toughness

- High hardness

- Outstanding wear resistance, both impingement and frictional modes

- Good thermal shock resistance

- Good chemical resistance

Typical circular si3N4 insulating ring applications include:

- Bearing balls and rollers

- Cutting tools

- Valves, turbocharger rotors for engines

- Turbine blades

- Glow plugs

- Molten metal handling

- Thermocouple sheaths

- Welding jigs and fixtures

- Welding nozzles

Advanced Finishing Services:

Innovacera specializes in high tolerance machining, grinding and polishing. Our state-of-the-art equipment allows us to offer a variety of machining services including:

- Precision grinding and machining

- CNC machining and grinding

- Lapping and polishing

- Threading

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- lalal

- Address

- Unit 4G,West Side,Lianchang bldg,No.6-8 Huli Avenue,Huli District,Xiamen,Fujian,China,361004

- Product Category

- Ball Bearings

- No. of Total Employees

- 1-50

- Company introduction

-

Innovacera offers a full range of solutions for supporting parts during sintering in reducing or oxidizing atmospheres up to 1800ºC. Innovacera has the industry's broadest range of manufacturing methods - including vacuum forming, casting, pressing and CNC machining. Mullite, alumina and alumina-zirconia compositions are available for applications in sintering of technical ceramic, electronic ceramic, and powder metal parts.

- Main Product

Related Products

Zirconia Zirconium Oxide Ceramic Ball Valves

Ceramic semicondouctor part

Ceramic processor scrap

Ceramic Valve Seats

Wear & Corrosion Resistant Si3N4 Silicon Nitride Ceramic Bar

China

China