Rubber Punched Strip seals

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- rubber molded parts, rubber seal, rubber strips, tank part

- Category

- Other Rubber Products

Global Sealing Systems INC.

- Verified Certificate

-

10

| Product name | Rubber Punched Strip seals | Certification | - |

|---|---|---|---|

| Category | Other Rubber Products | Ingredients | - |

| Keyword | rubber molded parts , rubber seal , rubber strips , tank part | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 401693 |

Product Information

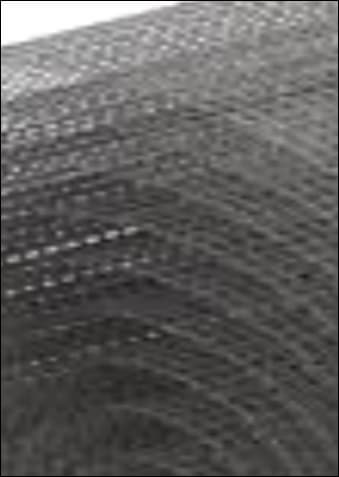

GLOBAL SEALING SYSTEMS is Rubber Rolls & Rubber Molded Parts producing

and selling company. One of our main products, Rubber Punched Strip Seals

are slit-to-width rolls of rubber with holes punched at precise uniform intervals,

perfectly suited to sealing between bolted or riveted panels of medium to large

sized tanks. GSSK equipped to manufacture virtually any type of rubber, any

width, and any holes size or spacing configuration.

Typical application

Door seals for silos and tank to provide sealing for products such as sugar,

flour, oils, chemicals and other all kinds of contents.

Available Materials

GSS Rubber Punched Strip Seals are available in the following materials

(Popular varieties include Neoprene RUBBER PUNCHED STRIP SEALS impression

for general purpose.)

Nitrile Rubber (Buna-N)

Used for petroleum products

White Nitrile(FDA approved)

→good for general purpose food and medical products storage.

EPDM

Superior weather resistance

Economical general purpose tank sealing material.

Silicone rubber

Suitable for both low and high temperature extremes as well as food and medical products.

Viton

Suitable for both high temperatures and chemically volatile

environments.

Various non-rubber gasket sheeting material

sponge rubber, foam, plastic etc.

Thickness

Average thickness for punching is between 1/16”~1/14”(1.6mm~6.4mm) for most tank sealing applications. However this is not a limitation and GSS easily apply the same prosses to thinner and thicker varietied of rubber and other materials.

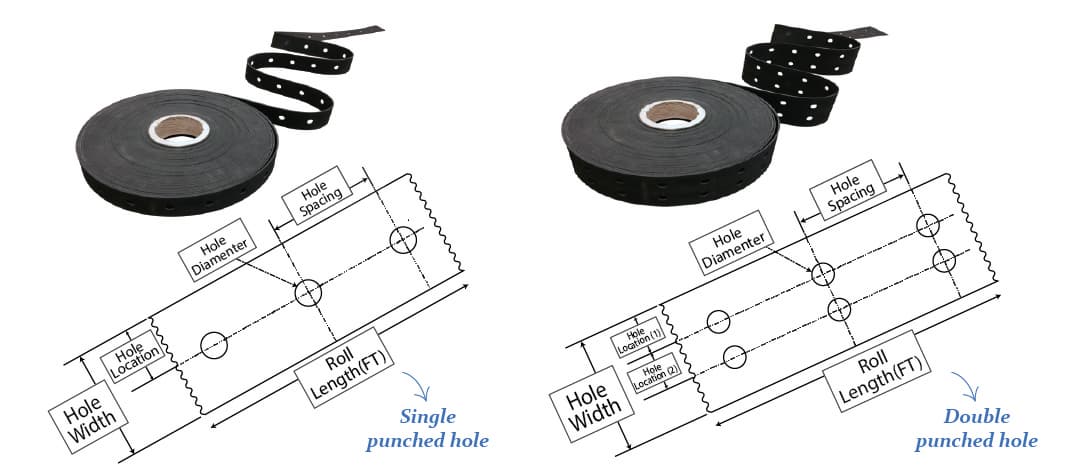

Hole Shapes, Size, and Spacing

GSSK can manufacture virally any holes pattern, and can even supply oval, square, or alternate shaped holes. Of coures, all rubber materials are available in |slit-to-width rolles without any holes, as well.

Seal Length & Width

Tank stripping is usually

sold by uncut roll size, which varies by thickness and variety between 25 and

300 foot lengths.

Naturally, we can generally cater to special requirements on Roll length.

Dimensional Tolerances

Tolerances vary according to material and dimension specifications, but typically runs around +/-.015 inches on key dimensions like width and hole diameter.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

Global Sealing Systems INC.

-

10

- President

- Kerry Rhee

- Address

- Centum jungang-ro, 97,(48058) A-2511, Haeundae-gu, Busan, Korea

- Product Category

- Insulator

- Year Established

- 2006

- No. of Total Employees

- 1-50

- Company introduction

-

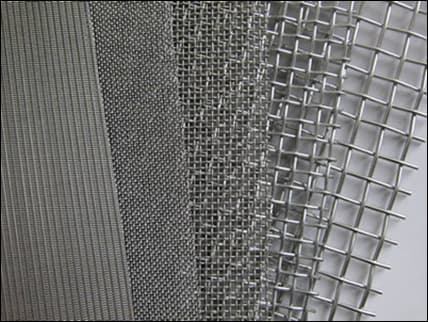

Global Sealing SystemsEMI/RFI Shiedling/Wire Mesh Company

Competitve Strength

-Automatic Facilities

-Up to 6 layers of Wire mesh

-Density Adjustment

-Durability

Manufacturing Facilities

One of GSS’s competitive advantages is Automatic Utility. With our exceptional technology, we have been able to make cost minimization and Quality Improvement come true.

“Reliability of function at lowest cost, resulting from good design and the use of capable processes.”

This is GSS’s mission to our customers!

- Main Markets

-

Brazil

Brazil

Canada

Canada

France

France

Germany

Germany

Mexico

Mexico

- Main Product

- Attached File

Related Products

China Solid EPDM Rubber Extrusions Manufacturer

EPDM RUBBER FOAM

door seal strip

Glass Silicone Vacuum Bag For EVA Laminating Furnace

unvulcanized rubber compound

South Korea

South Korea