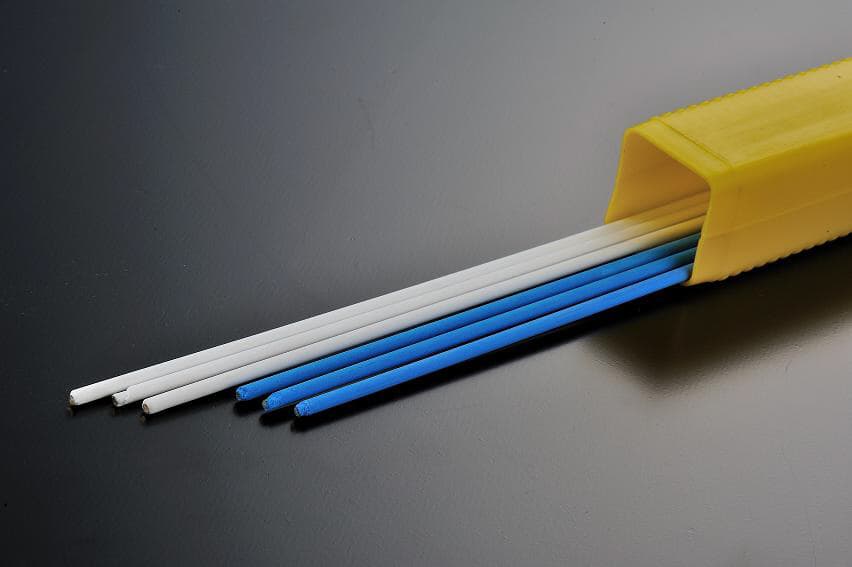

ALUMINUM BRONZE WELDING RODS

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China,South Korea

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Welding Rods & Tips

COMARTCO

- Verified Certificate

-

17

| Product name | ALUMINUM BRONZE WELDING RODS | Certification | - |

|---|---|---|---|

| Category | Welding Rods & Tips | Ingredients | - |

| Keyword | aluminum brazing paste alloy , aluminum bronze bar , aluminum bronze rods | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China,South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

| Standard | Alloy | Chemical Composition(%) | Melting Range | Application | |

| Solidus | Liquidus | ||||

| AWS A5.7 BS EN14640 | ERCuAl-A1 CuAl8 | Cu:Bal. Al:6.0-8.5 Mn:0.5 Si:0.1 Zn: 0.2 Other:0.5 | 1030℃ | 1040℃ | Prefer for joining welding of pure and austenitic steel sheet. Maintains good temperament flow and creates seamless welding line.Suggested for the joning welding of copper with steel,particularly suitable for machinery and shipbuilding industry.Pulsed arc welding is recommended for multilayer on steel. |

| AWS A5.7 BS EN14640 | ERCuAl-A2 CuAl10 | Cu:Bal. Al:8.5-11.0 Fe:0.5-1.5 Si:0.1 Zn: 0.2 Other:0.5 | 1030℃ | 1090℃ | Particular suitable for the overlay welding of copper,aluminum,and nickel material with steel. It has increased resistance to wear and abrasion,as well as superior corrosion resistence to seawater. Widely used for ship constructions, apparatus and plumbing. For multilayer welding on steel, pulsed arc welding is recommended |

| AWS A5.7 BS EN14640 | ERCuAl-A3 CuAl11Fe | Cu:Bal. Al:10.0-11.5 Fe:2.0-4.5 Si:0.1 Zn: 0.1 Other:0.5 | 1030℃ | 1045℃ | Recommended for the joining and overlay welding of copper-aluminium alloy, aluminium coated steel and cast iron .It has been widely used in shipbuilding, machery, and the chemical industry. Best for high overlay welding requirement for hardness,resistance to wear, abrasion, and erosion. |

| BS EN14640 | CuAl8Ni2 | Cu:Bal. Al:7.0-9.5 Fe:0.5-2.5 Mn:0.5-2.5 Ni:0.5-3.0 Si:0.2 Zn: 0.2 Other:0.4 | 1030℃ | 1050℃ | Recommended for the joining and overlaying of copper-aluminium alloy, aluminium coated steel in machinery and chemical industry as well as for iron welding in shipbuilding.Also excellent for the join welding of brass tube and copper-aluminium that requires resistance to erosion. |

| AWS A5.7 BS EN14640 | ERCuNiAl CuAl9Ni5 | Cu:Bal. Al:8.5-9.5 Fe:3.0-5.0 Mn:0.60-3.5 Ni:4.0-5.5 Si:0.1 Zn: 0.1 Other:0.5 | 1015℃ | 1045℃ | Particularly suitable for welding casting and forging products of Cu-Al-Ni Material such as propellers,bearing weights,vlaves,pumps and pipe systerms.Very good corrosion resistance to seawater. |

| AWS A5.7 BS EN14640 | ERCuMnNiAl | Cu:Bal. Al:7.0-8.5 Fe:2.0-4.0 Mn:11.0-14.0 Ni:1.5-3.0 Si:0.1 Zn: 0.15 Other:0.5 | 945℃ | 985℃ | Best for the overlay welding of iron-casting and non-alloy steel that especially need corrosion resistance. Also good for overlay welding of cast iron,non-alloy and low-alloy steel that requirement corrosion resistance. |

| Product Information: | MIG: 0.8mm 1.0mm 1.2mm 1.6mm 5kg/12.5kg/15kg spool | ||||

| TIG: 2.0mm 2.4mm 3.0mm 3.2mm 4.0mm 5.0mm 5kg/10kg polybag | |||||

| Flux Coated Rods Available | |||||

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- LEE MI OK

- Address

- 2F Digtal 27 Road, 67, Seoul, Korea

- Product Category

- Machinery & Parts,Other Machinery & Industry Equipment

- Year Established

- 2010

- No. of Total Employees

- 1-50

- Company introduction

-

We are very pleased to take this opportunity to introduce our company to your esteemed company, we have been grownto be what we are now, and we owe sucessful business growth much to your special and encouragement for which we are very appreciate. Since the establishment in 2001, COMARTCO have carried on business as a specialized distributor for spare parts of HVAC/R(Heating, Ventilation, Air-Conditioning and Refrigeration) in Korea.

And also, we have provided industrial materials, Copper and Copper alloys Pipes & Tubes, Fittings, Flanges and various kinds of Valves for Oil, Water, Gas and Heat Exchanger since 2005 with good quality products and good reputation. Under dynamic management, we trust that we can satisfy our customers with products of good quality and competitive prices.

We can sure that we will provide best after sales service and wealways try our best to offer the greatest values to our all customers. We would promise to maintain our goods reputation, and to help customer to make abundant profits.

We will take our role loyally in equipping ourselves better and solving what you long for,

ceaselessly, and we earnestly wish to be a good help for your prosperous business and we would also like to ask for your continual support and encouragement.

- Main Product

Related Products

INCONEL ALLOY Welding Tig rod , Mig Wire

Gouging Torch / Blasting Torch

TOKAI YOGYO welding rod

Spot Welding Tips

E6013 Welding electrode for carbon steel

South Korea

South Korea