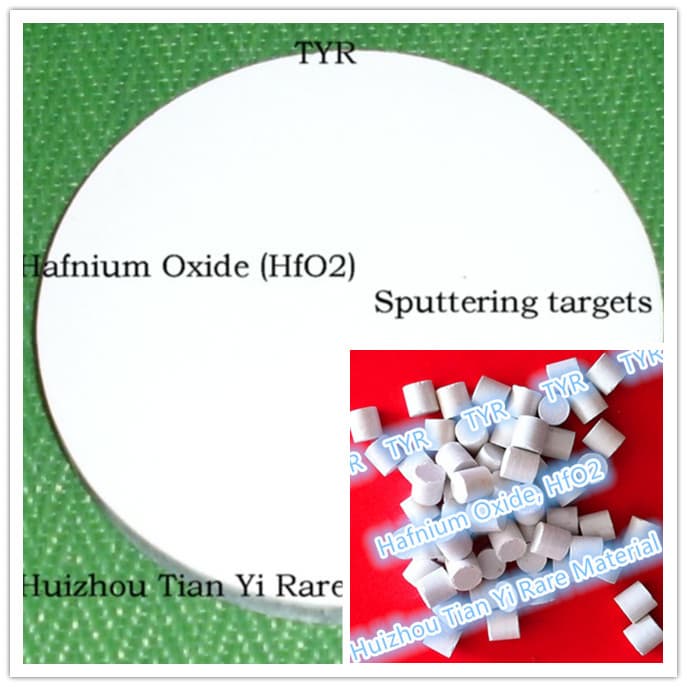

Hafnium oxide, HfO2, sputtering target, evaporation material, thin film coating material

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- evaporation, sputtering target, hafnium, thin film

- Category

- Industrial Supplies , Other Chemicals , Semiconductors , Oxide

Huizhou Tian Yi Rare Material Co.,Ltd

- Verified Certificate

-

10

| Product name | Hafnium oxide, HfO2, sputtering target, evaporation material, thin film coating material | Certification | - |

|---|---|---|---|

| Category |

Industrial Supplies

Other Chemicals Semiconductors Oxide |

Ingredients | - |

| Keyword | evaporation , sputtering target , hafnium , thin film | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Hafnium oxide, HfO2 CAS: 12055-23-1

Hafnium oxide (HfO2) product list from TYR as following:

High pure Hafnium oxide (HfO2) powder: purity: 99.95%, 99.99%, powder size: <10um, -325 mesh e.t.c

Hafnium oxide (HfO2) Sputtering targets: purity: 99.95%, 99.99%, Size: max. 355.6mm (14 inch) , Length: 250mm x Width 200mm x thickness 20mm max., Shape: Discs, disks, step disk, delta, plate, sheets or made per drawing, Color: White or black (see item descr.)

Hafnium oxide (HfO2) Evaporating coating material: purity: 99.95%, 99.99%, Size: 8 x 6, 10 x 8, 1-6mm or made per requested, Shape: Sintered pieces, tablets, chunks, pellets e.t.c, Color: White or black (see item descr.)

Molecular Weight: 210.49g/mol., Density: 9.68g/cm3, Melting Point: 2758°C, , Softening temp. : ~1100- 1500°C, Boiling Point : 5400°C, Bulk Density; 1922-2883 kg/m3, Solubility In Water, insoluble Appearance: white powder

Hafnium oxide (HfO2) is the inorganic compound with the formula HfO2. Also known as hafnia, this colourless solid is one of the most common and stable compounds of hafnium. It is an electrical insulator with a band gap of approximately 6 eV. Hafnium dioxide is an intermediate in some processes that give hafnium metal.

Hafnium oxide (HfO2) is quite inert. It reacts with strong acids such as concentrated sulfuric acid and with strong bases. It dissolves slowly in hydrofluoric acid to give fluorohafnate anions. At elevated temperatures, it reacts with chlorine in the presence of graphite or carbon tetrachloride to give hafnium tetrachloride.

Applications:

Hafnium oxide (HfO2) is a high-index, low absorption material, used in optical coatings, and as a high-k dielectric in DRAM capacitors, typical applications include near-UV laser AR and dielectric mirror designs. Hafnium-based oxides are currently leading candidates to replace silicon oxide as a gate insulator in field effect transistors. The advantage for transistors is its high dielectric constant: The dielectric constant of HfO2 is 15.6, whereas the dielectric constant of SiO2 is only 3.9.

The compound appears to have been chosen by both IBM and Intel as a substrate for future integrated circuits, where it may help in the continuing effort to increase logic density and clock speeds, or to lower power consumption, in computer processors.

Because of its very high melting point, hafnia is also used as a refractory material in the insulation of such devices as thermocouples, where it can operate at temperatures up to 2500 °C

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Amy Chiu

- Address

- 12 K of Shiji, Shijixingtian Bldg, YanDa Road, Huizhou, China

- Product Category

- Industrial Supplies,Other Minerals & Metallurgy Products,Semiconductors

- No. of Total Employees

- 1-50

- Company introduction

-

TYR has been established in 2004 year, specializes in a wide category of sputtering targets, evaporation source material, rare earth material and chemistry reagent, PVD materials base on metals, alloys, compounds. we offer targets bonding service, we serving government research establishments, universities and high technology industries. We using a variety of specialized processes including hot pressing, hot/cold isostatic pressing, and vacuum melting, vacuum sintering, we can provide the kind of homogenous, fine-grained, high-density materials that conform to the strictest quality control, we always aim to put quality first. Our product list include Metal sputtering targets, Alloy sputtering targets, Noble metal sputtering targets, Noble alloy sputtering targets, Oxide Ceramic Sputtering targets, Boride Ceramic Sputtering Targets, Carbide Ceramic Sputtering Targets, Fluoride Ceramic Sputtering Targets, Nitride Ceramic Sputtering Targets, Sulfide Ceramic Sputtering Targets, Selenide Ceramic Sputtering Targets, Silicide Ceramic Sputtering Targets, Telluride Ceramic Sputtering Targets, metal evaporation source, alloy evaporation source, optical thin film coating material, rare earth oxide and each high pure chemistry reagent. Sputtering Targets Materials list: High Pure Metal Sputtering Targets: Aluminum (Al),Antimony (Sb), Bismuth (Bi), Boron (B), Cadmium (Cd), Cerium (Ce), Chromium (Cr), Cobalt (Co), Copper (Cu), Dysprosium (Dy), Erbium (Er), Eur (Eu), Gadolinium (Gd), Germanium (Ge), Gold (Au), Graphite, (C), Hafnium (Hf), Holmium (Ho), Iridium (Ir), Indium (In), Iron (Fe), Lanthanum (La), Lead (Pb), Lutetium (Lu), Manganese (Mn), Molybdenum (Mo), Magnesium (Mg), Neodymium (Nd), Niobium (Nb), Nickel (Ni), Palladium (Pd), Platinum (Pt), Praseodymium (Pr), Rhenium (Re), Ruthenium (Ru), Samarium (Sm), Scandium (Sc), Selenium (Se), Silicon (Si), Silver (Ag), Tantalum (Ta), Terbium (Tb), Tellurium (Te),Tin (Sn), Thulium (Tm), Titanium (Ti), Tungsten (W), Vanadium (V), Ytterbium (Yb), Yttrium (Y), Zirconium (Zr), Zinc (Zn) ; Alloy Sputtering Targets: Al alloy targets, Al-Cu, Al-Cr, Al-Nd, Al-Si, Al-Si-Cu, Al-Ag Cu alloy targets: Cu-Ag, Cu-Co, Cu-Ga, Cu-In, Cu-Ni Co alloy targets: Co-Cr, Co-Cr-Mo, Co-Fe, Co-Fe-B ,Co-Ni, Co-Ni-Cr, Co-Pt Ni alloy targets: Ni-Al, Ni-Cr, Ni-Cr-Si, Ni-Fe, Ni-Mn, Ni-Ti, Ni-V, Ti alloy targets: Ti-Al, Ti-Ni, Ti-Zr, Ti-Co Ta alloy targets: Ta-Al, Ta-W W alloy targets: W-Ti, W-Mo, W-B, W-Re Mo alloy targets: Mo-Nb, Mo-Si, Mo-Al Fe alloy targets: Fe-B, Fe-Co, Fe-Mn, Fe-Hf, Fe-Gd, Fe-Tb Zr alloy targets: ZrAl, ZrCu, ZrFe, ZrNb, ZrNi, ZrTi, ZrY, Noble alloy targets: Au-Ag, Ag-Cu, Ir-Mn, Ir-Re, Ir-Ru, Au-Sn, Ag-In, Ag-Sn e.t.c Ceramic sputtering target: Oxide Ceramic Sputtering targets: Al2O3, AZO, Sb2O3, ATO, BaTiO3, Bi2O3, CeO2, CuO, Cr2O3, Dy2O3, Er2O3, Eu2O3, Gd2O3, Ga2O3, GeO2, HfO2, Ho2O3, In2O3, In2O3-SnO2 (ITO), Fe2O3, Fe3O4, La2O3, PbTiO3, PbZrO3, LiNbO3, Lu2O3, MgO, MoO3, Nd2O3, Sm2O3, Sc2O3, SiO2, SiO, SrTiO3, SrZrO3, Ta2O5, Tb4O7, TeO2, Tm2O3, TiO, TiO2, Ti3O5, Ti2O3, SnO2, SnO, WO3, WO3-Li, V2O5, VO2, Yb2O3, Y2O3, Y2O3-ZrO2 (YSZ), YBCO, ZnO, ZnO:Al, ZnO-In2O3, ZrO2, ZrO2-5-15wt%CaO) Boride Ceramic Sputtering Targets: Cr2B, CrB, CrB2, FeB, HfB2 ,LaB6, Mo2B, Mo2B5 ,NbB, TaB2, TiB2, W2B5, WB, VB, YB6, ZrB2 Carbide Ceramic Sputtering Targets : B4C, Cr3C2, HfC, Mo2C, NbC, SiC, TaC, TiC, WC, W2C, VC, ZrC Fluoride Ceramic Sputtering Targets : AlF3, BaF2, CaF2, LiF, MgF2, NaF, Na3AlF6, YF3, YbF3 Nitride Ceramic Sputtering Targets :AlN, BN, HfN, NbN, Si3N4, TaN, TiN, VN, ZrN Sulfide Ceramic Sputtering Targets: CuS, Cu2S, CdS, FeS, FeS2, GeS, SnS, In2S3, MoS2, TaS2, WS2, ZnS Selenide Ceramic Sputtering Targets: Bi2Se3, CdSe, CuSe, Ga2Se3, In2Se3, PbSe, MoSe2, NbSe2, TaSe2, WSe2, ZnSe Silicide Ceramic Sputtering Targets: Cr3Si, CrSi2, CoSi2, HfSi2, MoSi2, NbSi2, TaSi2, Ta5Si3, TiSi2, Ti5Si3, WSi2, V3Si, VSi2, ZrSi2 Telluride Ceramic Sputtering Targets: Bi2Te3, CdTe, CuTe, Ga2Te3, GeTe, PbTe, MoTe2, NbTe2, TaTe2, WTe2, ZnTe

- Main Markets

-

Egypt

Egypt

France, Metropolitan

France, Metropolitan

Germany

Germany

Hong Kong(China)

Hong Kong(China)

India

India

Japan

Japan

South Korea

South Korea

U. Kingdom

U. Kingdom

U.S.A

U.S.A

- Main Product

Related Products

Micro Slack Wax WX-160S, Microcrystalline Wax

PVC/Vinyl Wire End Caps

LDPE Film Scraps

Stainless Steel 304 Heavy Gauge Welded Mesh

clad steel(Ecoteel)

China

China