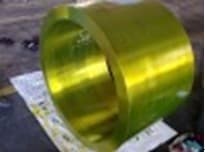

generator retaining ring

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- forging, retaining ring, generator part

- Category

- Generator Parts & Accessories

SICHUAN DEYANG KELY MACHINERY EQUIPMENT MANUFACTURE CO., LTD.

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | generator retaining ring | Certification | - |

|---|---|---|---|

| Category | Generator Parts & Accessories | Ingredients | - |

| Keyword | forging , retaining ring , generator part | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | 8406909000 |

Product Information

Specification:

Ring :

1. according to Customer's drawing.

2. High Quality

3. Rings- parts: Diameter ≤ Φ8000mm

Weight ≤ 30T

forged retaining ring for turbine-driven generator (18Mn18Cr) is customized which can be rough machining or finish maching.

1- chemical composition

As per standard of ASTM A289

2- As per standard of ASTM A342-1995 Standard Test Methods for Permeability of Feebly Magnetic Materials

4- metallographic tests. As per standard of ASTM E112:1981 (eqv. YB/T 5148-1993) Standard Test Methods for Determining Average Grain Size

5- mechanical properties. As per standard of ASTM A370-1997 Standard Test Methods and Definitions for Mechanical Testing of Steel Products; As per standard of ASTM E112:1981 (eqv. YB/T 5148-1993) Standard Test Methods for Determining Average Grain Size; As per standard of ISO738:1989 (eqv. GB/T 4338-1995) Metallic materials-Tensile testing at elevated temperature

6- non-destructive tests, As per standard of ASTM A531-1974 (eqv. JB/T 4010-1985) Standard Practice for Ultrasonic Examination of Turbine-Generator Steel Retaining Rings; As per standard of ASTM E165-1995 Standard Test Method for Liquid Penetrant Examination

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- MR GE LIANG

- Address

- NO. 16, WEST DONGHAI ROAD, JINGYANG DISTRICT, DEYANG, SICHUAN, 618000, CHINA

- Product Category

- Gas Turbine Generators,Generators,Other Energy Related Products

- No. of Total Employees

- 101-500

- Company introduction

-

Sichuan Deyang Kely Machinery Equipment Manufacture Co. Ltd.( shortly called SDKME), in September, 2004, with registered capital RMB 36million and total asset RMB 220million,is a modern private enterprise specializing in customized fabricating and machining the critical parts or assembly of nuclear energy, wind power, coal fired power,hydropower, gas turbine etc. power industry, petrochemical and mining industry etc. heavy equipments as a top partner of China National Heavy Equipment Manufacture Base in Deyang, Sichuan, and also a developing medium and small enterprise cared for and supported by local provincial and city governments.

Located in Jingyang District Industry Development Zone, Deyang, SDKME covers an areas of 120,000 square meters with standard steel structure shops built of 28,000 square meters. We have the manufacture facilities as follows: one set of CNC Boring & Milling machine TJK6920 in 5×12 m, one set of CNC Floor Boring & Milling machine TJK6920 in 6×16 m, one set of CNC Boring & Milling machine TJK6920 in 4×10 m, one set of fixed door and rotary beam type CNC gantry boring & milling machine QLM 24-40120 in 5×12 m, one set of double column and a fixed beam type CNC vertical Lathe in Dia.8 m, one set of CNC vertical lathe with single arm and rotary beam in dia. 14 m, one set of CNC floor boring machine TK 6926 in 8 × 26m, one set of CNC gantry boring & milling machine SLM 2370 in 8×22m, two sets of CNC horizontal lathe CW61190L/500 in 2 × 5m, two sets each of slide rest type drilling machine Z33100 and slide rest type drilling machine Z33125, one set of Hydraulic press in 500T, one sets each of rolling maching in 30×3000, 20×2000, 60×4500, six sets of CNC gas cutting machine CC500, one set of automtic heat treatment furnace in 6.5×12m, two sandblasting shops in 17m, bridge cranes respectively in 50T, 75T, 100T and 200T, totally 45 sets of machining facilities, which forms our strong manufacturing ability in customizing the large steel structure fabrications and the equipments.

We are certified ISO 9001:2008 Quality Management System and forms a complete production line of CNC cutting,welding,heat treatment, sand blasting, machining and assembling by technology innovating in the projects, so our manufacturing capacity has increase greatly with annual welding output max: 1000 tons of steels and annual finish machining output value: RMB 100 million,such as 400 pcs of TBN casings in LP, IP and HP of steam turbine at 50~1000MW. We mainly devote ourselves into the deveopment and production of the auxiliary fabricated and machined parts for the large equipments with capacity target: RBM 120 million. With the perfect processing technology in fabricating and machining the customized parts for nuclear turbine, coal fired power, wind turbine, hydro turbine, petrochemical, mining etc. large machinery equipments,we have formed an integrated system of the design, deveolpment, production, supply and marketing in our own company.

Located in Deyang city famous for Chinese Heavy Equipment Manufacture Base with superior region condition, we have succeeded in cooperating with Dongfang Turbine Co., Ltd, DFEM, China Erzhong, Sichuan Honghua etc. famous key enterprises, also jointly manufacturing the gas turbine fabricated and machined parts with MHI, a top 500 global manufacturer. Adhering to the principle of survival by the quality, marketing by credit, we have successively manufactured and supplied lots of performance fabricated and machined parts or units for national defense, new energy and machinery etc.industries with the good appraisal by our clients.

Emphasizing our economic benefits, we also pay our attention to our corporate social responsibility. Through our endless efforts, we have been assessed and awarded as the excellent enterprise, the contract and trustworthy enterprise, the advanced skill-contesting enterprise respectively by The People's Government of Jingyang District and The People's Government of Deyang City, The Disaster-Relief Workers' Pioneer Title for Wenchuan Earthquake 2008 by the Labor Union of Sichuan Province.

We have an expert management team and extraordinary technical team of a rich experience, employees of 301, of whom, 117 technicians, including 7 senior engineers, 9 engineers, 16 senior technicians, 85 skilling workers. To heartedly build the key partnership enterprise of Chinese Heavy Equipment base, we continuously enhance the investment in the technology-innovating and technological update. We invested RMB75 million into the 1000MW nuclear gas H P& I P outer casing equipment and updated technology project in 2011, and our technology center was certified to be the city level enterprise technology center by the Deyang city Authority.

Relying on the enterprise spirit of base on human being, better by innovation and stronger by firm ambition and complying to the principle of quality first, credit uppermost, we are equipped with high investment, high-tech, advanced facility and subtle management and supply the most performance products with the customers home and abroad, we try our best to satisfy the unceasing development of the machinery industry through our own advantage of talent, information, quality and efficiency.

- Main Markets

-

South Korea

South Korea

- Main Product

Related Products

Perkins 60HZ Generator

Vertical Axis Wind Turbine (VAWT VA-VP Series)

Ecomax+

Cold Extrusion Parts Claw Poles cold extrusion manufacturer

750 kVA Mirrlees Blackstone ETSL8 Diesel Engine