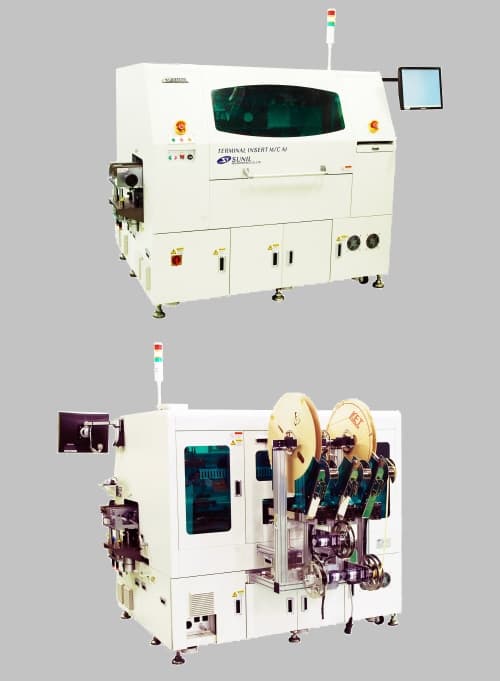

Terminal Auto Insertion Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Machinery & Industry Equipment

Sunil Mechatronics Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

16

| Product name | Terminal Auto Insertion Machine | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | pin machine , auto insert machine , terminal insert machine | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

*STANDARD FEATURES

-Excellent insertion speed with less sound

-Follow-up service and reliability through a verified PLC

-Excellent durability and repetition at a high degree of precision on the X-Y table with an LM Guide Actuator

-Improved durability and reduced noise through the use of a monolithic high strength frame

-Improved degree of precision at the PCB support position with cam technology on the back-up plate

-The back-up plate works well with a large size PCB.

-The plate carved in is lied one upon another beneath PCB, immobilizing it in order to keep the PCB from being damaged and stop terminal pin from leaning to one side on its level while inserting terminals on the PCB.

-In the servo-off mode, the head and cam are operated manually.

*TURNTABLE

-The DD motor, which is located in the center of the table, prevents back lash and helps to stabilize table turning.

*FOUR WHEEL MONOLITHIC CAM SYSTEM HEAD

-With no need for adjustment, the four-wheel monolithic cam system head is durable as minimized surface friction.

-And, the head has the easy replacement of consumable parts that attach to it.

*ACCURATE SYSTEM CONTROL AND DATA MANAGEMENT

-All systems of the AI-03 are controlled by the PLC. The management software, based on the computer’s GUI, creates various settings.

-During operation, the PLC guarantees stability and the software maximizes convenience through continuous monitoring of data.

*VISION & CAM

-The vision system makes it possible to view the insertion hole center, with a high degree of precision.

-It precisely controls the height inside each terminal hole of the PCB through an excellent, high-speed four wheel monolithic cam system.

1. FUNCTION FOR DETECTION OF INCORRECT PCB DIRECTION FLOW

-Detects incorrect PCB flow with the vision system after the PCB moves onto the plate.

2. FUNCTION FOR PCB ALIGNMENT CORRECTION

-Detects the fiducial mark, once the PCB moves onto the plate, and correctly adjusts the coordinate system, which is relevant for insertion.

3. OTHER FUNCTIONS FOR COORDINATE REVIEW AND CORRECTION

-Reviews all PCB holes and adjusts its exact location according to coordinates.

*INSERTION TOOL ANTI-DAMAGE

-This system prevents damage to the tool’s head by impacts between the insertion tool and cutter.

-It also detects objects that are caught in the cutter or its die.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- KIM MYUNG CHEOL

- Address

- 3-10, Horim-dong, , Dalseo-gu, Daegu, Korea

- Product Category

- Other Machinery & Industry Equipment

- No. of Total Employees

- 1-50

- Company introduction

-

Established in 1997, SUNIL Mechatronics became the first in the world to successfully develop automation facilities for semiconductor plants and further for LCD and automobile plants. SUNIL supplies Leading Machines for Chip Array that automatically set semiconductors and also supplies 1st band companies for assembling junction boxes, which are parts of automobile tuning kits with Auto Insertion Machine AI-03 which inserts terminals on PCB in fuse boxes. To develop these precision devices, SUNIL has dedicated 70% of its total work force to continuous R&D.

SUNIL was credited for the excellent works then selected as a Star Company (2010) in Daegu, Korea. With ISO 9001 and ISO 14001 as well as Venture Business and INNO-BIZ certificates, SUNILs products include MLCC Loading M/C, Electrode Furnace Loading M/C, Multistage Tantalum Packing M/C and Auto Si Sealing M/C. For example, its MLCC Loading M/C, a device that aligns and inserts a certain amount of MLCC elements for the dipping process, features increased accuracy of its press using a precision servo motor, fine adjustment using a feed controller at the product supply point, prevention of out-of-limits dimensions with a two-inspection process, etc.

- Main Markets

-

China

China

Hungary

Hungary

Poland

Poland

South Korea

South Korea

- Main Product

,_Smartphone_dryer,_heating_mobile_2.jpg)