Alcotex FR

ALCOTEX/FR Aluminum Composite Material(ACM) , premier choice for an exterior cladding of Builoding Exterior structure

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- ALCOTEX FR

- Payment Terms

- L/C,T/T

- Production method

- Available,OEM

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Aluminum Composite Panels

DAE MYUNG HWA SUNG CO LTD

- Membership

- VIP

- Recent Visit

- Dec 20, 2024

- Country / Year Established

-

South Korea

/

1991

South Korea

/

1991

- Business type

- Manufacturer

- Verified Certificate

-

16

| Product name | Alcotex FR | Certification | - |

|---|---|---|---|

| Category | Aluminum Composite Panels | Material | - |

| Keyword | acp , aluminium composite panel , aluminum composite panel , building material | Unit Size | - |

| Brand name | ALCOTEX FR | Unit Weigh | - |

| origin | South Korea | Stock | 500 |

| Supply type | Available,OEM | HS code | 761090 |

Product Information

ALCOTEX® / FR

Aluminum Composite Panel ( ACP )

Noncombustible Aluminum Composite Panel

Environment friendly Building Exterior Materials

ALCOTEX /FR is very price competitive against conventional exterior materials such as aluminium sheets, enamel sheets, honeycomb panel, and marble.

Specification

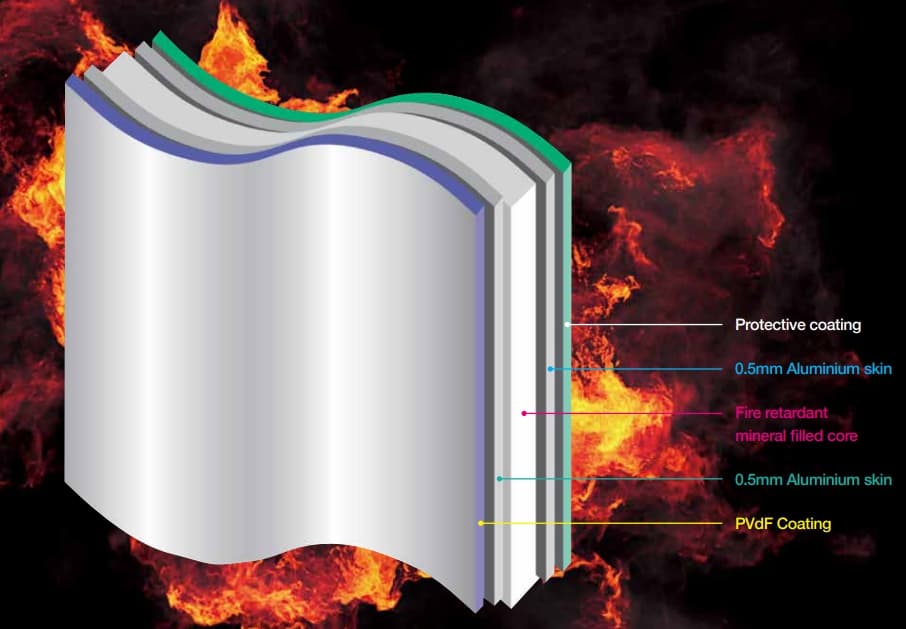

1) THICKNESS of FR : 0.5mm(aluminium) + 3mm(FIRE RETARDANT CORE) + 0.5mm(aluminium) = 4mm

2) FINISH : 2 COAT PVDF COATED(FRONT SIDE), + POLYESTER COATED ( BACK SIDE)

3) 3 Widths available : 1020mm, 1250mm, 1575mm.

4) Length : Upto 5000mm

- 2000mm, 2010mm, 2020mm also available and 5,000mm is recommended for convenient delivery and handling.

6) Minimum Order Q'ty : 500sqm per width and per color

7) Package : Export standard packing

ALCOTEX® / FR

Aluminum Composite Panel ( ACP )

Noncombustible Aluminum Composite Panel

Environment friendly Building Exterior Materials

Product features

ALCOTEX/FR Aluminum Composite Material is the premier choice for an exterior cladding that will maximize the beauty of your structure while providing a sustainable product to prolong the life of your building.

Alcotex ACM is a fusion of extremely flat PVdF coated aluminum enclosing a resin core which offers excellent corrosion resistance, stability against water and is highly scratch resistant.

Known for its consistency and rigidity, it has been designed for maximum architectural flexibility while retaining ease of machining and forming using ordinary metal and woodworking tools.

Alcotex is produced in a continuous process with a polyvinylidene fluoride (PVdF) coating containing a minimum of 70% Kynar 500®/Hylar 5000® resins which meets or exceeds AAMA 2605 and AAMA 620 performance requirement.

Advantages

Lightweight & rigid

Superior in flatness

Design flexibility

Durable surface finishes

Environmentally friendly

Fire safety and no toxic gas

Effective vibration / sound dampening control

Easy interface with other systems

Corrosion resistance

Less joints and clean look

No special maintenance

Composition of ALCOTEX/FR

Alcotex consists of two aluminum sheets sandwiching a solid core of extruded thermoplastic material processed in a continuous process with no glues or adhesives between dissimilar materials.

A protective film is applied to the material in production that should be removed after the fabrication and panels have been installed.

Top : 0.5mmm/0.020” aluminum skin coated with a PVdF roll-coated finish containing a minimum of 70% Kynar 500®/Hylar 5000® resins

Core : Mineral based fire rated (FR) core

Bottom : 0.5mm/ 0.020” aluminum skin coated with either a Mill finish or Polyester finish

2 COAT (SOLID & MICA COLORS) 3 COAT (METALLIC COLORS)

Alcotex finishes are applied in a reverse roller application process and are available in either a 2 or 3 coat finish. The 2 coat finish omits the clear coat required on a 3 coat finish. Both finishes will provide the same excellent performance required for architectural applications.

Solid & Mica / Pearlescent Colors

These 2 coat finishes will typically consist of a 0.2mm primer coat and a 0.8mm color coat for a nominal dry film thickness of 1mm

Metallic & Premium Colors

These 3 coat finishes will typically consist of a 0.2mm primer coat, a 0.8mm color coat, and a 0.5mm clear coat for a nominal dry film thickness of 1.5mm

Custom Colors

Custom Colors are available in either 2 or 3 coat finishes upon request. Please contact us to see how we can help you customize your project.

Aluminum Composite Panel ( ACP / FR )

1) THICKNESS / FR : 4MM ( 3MM up to 6MM available )

: 0.5mm ( Aluminum ) + 3mm ( FIRE RETARDANT CORE) + 0.5mm (Aluminum) = 4mm

2) FINISH : 2 Coat PVDF coated (TOP side) & Polyester coated ( Bottom side)

Testing data

Alcotex/FR aluminum composite material has been extensively tested at fully accredited testing facilities in North America. These test results meet or exceed the current testing requirements that should be expected to give the customer full confidence in selecting Alcotex for their project.

Dimensions

Thickness: 4mm standard with 3mm & 6mm also available

Width: 1020mm (40”), 1250mm (49”), & 1575mm (62”),

Length: Within 5000mm(196”) is recommended for convenient handling and deliver

Product Tolerance

Width: ± 2.0mm

Length: +3.0mm (not allowed minus error)

Thickness: ± 0.2mm

Squareness: Maximum + 2.0mm

Bow: Maximum 0.5%

Aluminum Skin: .5mm/.020”(nominal)

Fabrication Methods

Alcotex is a versatile product that may be easily fabricated in many different ways including:

• Cutting • Grooving • Bending / Folding • Curving • Drilling • Shearing • Punching • Riveting • Hot Air Welding

Sound Transmission Loss

With a triple sandwiched composite structure, Alcotex has an excellent physical impact absorbability and sound transmission loss especially when compared to other products. Alcotex ACM is great for effective vibration and sound dampening control.

Deflection By Wind Load

As well as being both lightweight and rigid, Alcotex is an extremely flat aluminum composite material. Alcotex has a high strength to weight ratio when compared to other exterior veneer products such as aluminum plate, stainless steel or porcelain

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | Ocean Shipping |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

DAE MYUNG HWA SUNG CO LTD

- Country / Year Established

-

South Korea

/

1991

South Korea

/

1991

- Membership

- VIP

- Recent Visit

- Dec 20, 2024

- Business type

- Manufacturer

-

16

- President

- KIM HYUNG MOAK

- Address

- JINYEONG-EUP, SEOBU-RO,219, Gimhae-si, Gyeongsangnam-do, Korea

- Product Category

- Aluminum Composite Panels,Other Constructions

- Year Established

- 1991

- No. of Total Employees

- 1-50

- Company introduction

-

We are DAEMYUNG HWASUNG CO., LTD. , manufacturing premium Aluminium Composite Panel (ACP) in Korea.

Products

1. Alcotex - FR ( FR brochure os as attached file )

* THICKNESS : 0.5mm(aluminium) + 3mm(FIRE RETARDANT CORE) + 0.5mm(aluminium) = 4mm

* FINISH : 2 COAT PVDF COATED (FRONT SIDE) + POLYESTER COATED ( BACK SIDE)

2. A-POLYCERAMIC ( A-POLYCERAMIC brochure in attached file )

=> Adding Polyceramic coating to Alcotex-FR for Non-pollution ACP

* THICKNESS : 0.5mm(aluminum) + 3mm(FIRE RETARDANT CORE) + 0.5mm(aluminum) = 4mm

* FINISH : 2COAT PVDF COATED + non-pollution coating (front side) POLYESTER COATED ( BACK SIDE)

* A-POLYCERAMIC is premium product with NON-POLLUTION COATING 20YEARS GUARANTEE.

ALCOTEX/FR Aluminum Composite Material is the premier choice for anexterior cladding that will maximize the beauty of your structure whileproviding a sustainable product to prolong the life of your building.

Alcotex ACM is a fusion of extremely flat PVdF coated aluminum enclosing aresin core which offers excellent corrosion resistance, stability against waterand is highly scratch resistant. Known for its consistency and rigidity,

it has been designed for maximum architectural flexibility while retainingease of machining and forming using ordinary metal and woodworking tools.

Alcotex is produced in a continuous process with a poly vinylidenefluoride (PVdF) coating containing a minimum of 70% Kynar 500®/Hylar 5000®resins which meets or exceeds AAMA 2605 and AAMA 620 performance requirement.

- Main Markets

-

Australia

Australia

Indonesia

Indonesia

Malaysia

Malaysia

Russia

Russia

Saudi Arabia

Saudi Arabia

- Factory Information

-

DAEMYUNG HWASUNG CO.,LTD.

- Main Product

- Attached File