poratable CNC cutting machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- cutting machine, plasma cutting machine, portable cutting machine, portable cnccutting machine

- Category

- Other Machinery & Industry Equipment

Jinan North Equipment Co.,Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

14

| Product name | poratable CNC cutting machine | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | cutting machine , plasma cutting machine , portable cutting machine , portable cnccutting machine | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

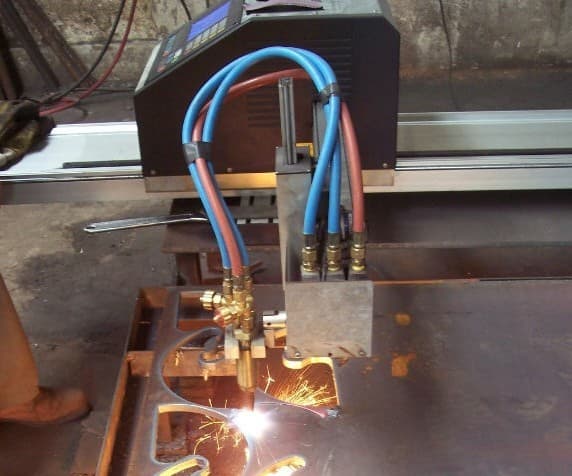

Product features of portable CNC cutting machine

(1) Working stability, high frequency interfere effectively plasma, lightweight portable;

(2) Support two cutting ways of flame and plasma;

(3) Economic benefits, the structure and design is contracted. it adopts humanistic positive man-machine conversation and operate easily;

(4) Cutting has high quality, high effect level, high precision.

(5) English and Chinese interface can free to convert;

(6) Pre-sale will train and after-sale will track service.

Portable numerical control flame plasma cutting machines can be programmed to cut any plane shape parts composed of beeline and arc, which are same as large gantry cutting machines. It is equipped with a 5.7 inch LTD with dynamic and static graphical display. It is directly perceived and very easy to learn .It can be programmed to cutting parts directly, and also can be operated in computer translating instructions into a program file by CAD program, and then deducing it via U hardware. The standard positioning of this machine is flame cutting, external hanging plasma cutter is also workable.

Product advantage:

Less investment, the higher cutting efficiency, lower operating and maintenance cost!

when cutting the thickness of the steel plate under 30mm , It has better advantage . Cutting costs about one-tenth of the laser cutting edge and one-sixth of water jet cutting.

This product is suitable for large, medium and small mines, widely used in automobile, shipbuilding, engineering machinery, agricultural machinery, suitable for carbon steel (flame cutting), and stainless steel.

Software and material

CAD drawings and computer graphics can be reduced to G code which used to cutting components,

Code file G deposit ORM, and input into the cutting machine, the system will automatically make the G code convert cutting program.

This product with USB interface, convenient program transmission. In material software Set cutting compensation.

一,Technical Parameter

1,Input voltage/power/frequency 220V±10%V/220W/50HZ。

2, LCD specifications 5.7 inch.

3, Effective cutting range of standard size :

NHC-1020 1000(width) ×2000(length)mm

NHC-1225 1250(width) ×2500(length)mm

NHC-1525 1500(width) ×2500(length)mm

Cutting length can be customized according to the customer’s require.

4, Vertical guide practical length × width × thickness

NHC-1020 1530×50×60mm

NHC-1225 1780×50×60mm

NHC-1525 2030×50×60mm

5, Horizontal guide practical length ×width× thickness

NHC-1020 1530×50×60mm

NHC-1225 1780×50×60mm

NHC-1525 2030×50×60mm

6, The number of track support

NHC-1020 2pieces;NHC-1225 3pieces;NHC-1525 3pieces。

7, Track support long × width × thickness 500×80×40mm。

8, Cutting thickness 5-150 MM (flame cutting)。

9, Cutting speed 50-2000(maximum4000)mm/min。

10, Plasma cutting depth Depending on the plasma power

11,Cutting way Flame (oxygen + propane or oxygen + acetylene)

Plasma (configuration plasma cutting machine),

12, Operation precision ±0.2mm/m。

13, Machining accuracy ±0.5mm/m。

14, Torch and height flame, electric turn up(±50mm)。

15, Applicable gas Oxygen + acetylene or oxygen+ propane

16,Host weight 20KG。

17, Gas pressure maximum 0.1Mpa

18, Oxygen pressure maximum 0.7Mpa

二、 Numerical Controls

1, 5.7 inches and high resolution LCD of Monitor . Displaying cutting graphics and cutting orbits. Operate more simplified.

2,Keyboard and buttons operating mode.

3,Support USB file. Also it can be manually edit cutting program (G code).

4,2 axis line and circular interpolation。

5,Support suspend workin-process suspending, forward, backward, speed governing and so on.

6, System has power failure of memory function and back parameter and automatic perforation cutting function.

7, System has manual and electric going up and down control function.

8, Has cutting gap compensation function.

9, Electronic clutch operation, convenient and realize rapid positioning (and stop button).

10, The temperature fan, and start up when need pneumatics. It can extend fan's life-span.

11, System can store 30 files, and each file can 2000 lines. U dish can be stored 2GB.

12, High-speed 16-bit single chip, FLASH storage procedures and external USB read transmission program.

13, High-subdivision stepping motor driver, smooth movement, low noise, high precision operation.

14, The cutting speed can set to maximum 4 meters per minute, that can meet the needs of plasma cutting.

15,Withstand high frequency interference, and it is adapted to all kinds of plasma machines.

三,Component parts

1,It is made up of the horizontal, vertical guide rails, and host.

2, The host part, the MOD adopts to prevent magnetic structure, ensure reliable and stable operation of the CNC system.

3, Driven is 1.8 ° stepper motor.

4, Horizontal and vertical guide use aluminum core shaft, In side has strengthened by mechanical principle, making its shape.

四,Function

Any back, the memory of power failure, shifting the torch, cutting any interruption, and electronic clutch switches etc. It is convenient to the manipulator.

五,Programming Software

NHC programming software (optional FASTCAM - TL) based on AutoCAD automatic programming and material system.

NHC - TL is designed for all kinds of NC cutter with cutting software, the software can help the user completing various complex parts drawing, programming, material, using convenient, also bring the obvious economic benefit.

(1) Methods: (1) using AutoCAD powerful function to draw parts drawing and material, and through DXF file data processing, automatically make cutting code.

(2) Craftwork processing: the point can be used the edge cutting or roll cutting, Cutting compensation function can calculate the center of the actual cutting track of the flame, it also can set direction and path cutting.

(3) Mating methods: based on the AutoCAD can make the material of parts graph translation, rotation, copy, mirror, scaling, array, etc. By the window technology enlargement processing.

(4) Screen simulation: cutting process can be simulated processing on the screen, simulation cutting process and scale, moving.

|

Models |

NHC-1020 |

NHC-1225 |

NHC-1525 |

|

Input power source |

220±10%V AC 50HZ 220W |

||

|

Cutting way |

Oxygen +propane or acetylene;Configurable plasma cutting machine |

||

|

Effective cutting range(mm) |

1000×2000 |

1250×2500 |

1500×2500 |

|

Guide long * width * thick (mm) |

2500×273×60 |

3000×273×60 |

3000×273×60 |

|

The number of track support |

2 |

3 |

3 |

|

Track support length × width × thickness mm |

500×80×40 |

||

|

Cutting speed mm/min |

50-2000(max 4000) |

||

|

Cutting thickness (Flame) mm |

5-150(Oxygen + acetylene or propane) |

||

|

Cutting thickness (Plasma)(mm |

plasma power |

||

|

Operation precision |

±0.2mm/m |

||

|

Torch and turn up |

flame,electric turn up(±50mm) |

||

|

Host weight(kg) |

20 |

||

|

Gas pressure (Mpa) |

Maximum 0.1 |

||

|

Oxygen pressure (Mpa)

|

Maximum 0.7 |

||

|

Applicable gas species |

Oxygen+ propane or acetylene |

||

|

This product in user no special requirements, with acetylene cut |

|

||

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- wang zhi gang

- Address

- Rm101,Building2,Pioneering Park For Overseas Scholars, No.19 Huaneng Road ,Jinan Shandong ,China

- Product Category

- Welding Equipment

- No. of Total Employees

- 101-500

- Company introduction

-

Jinan North Equipment Co.,Ltd is a sino-foreign joint venture enterprise , which is located in jinan pioneering park for overseas scholars . Ji Nan North Equipment Co.,Ltd is engaged in introducing the international high level products and technology.

We company manufactures welding positioning equipment such as welding positioners ,turning rolls , wire feeders , adjustable brackets and welding chucks . our company is specialized in R&D,manufacture , marketing and technical services of a variety of dc motors and welding and cutting auxiliary equipment .if you are in need of them , please call or email for information on all of our welding positioners ,turning rolls , wire feeders and welding chucks .

We are looking forward to your inquiry and hope a successful cooperation with you !

- Main Markets

-

Armenia

Armenia

Canada

Canada

Germany

Germany

South Korea

South Korea

- Main Product