ERW Steel Pipe-API 5L,ISO 3183,DNV OS-F-101

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Industrial Supplies

Metals International Limited

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

15

| Product name | ERW Steel Pipe-API 5L,ISO 3183,DNV OS-F-101 | Certification | - |

|---|---|---|---|

| Category | Industrial Supplies | Ingredients | - |

| Keyword | line pipe , steel pipe , electric resistance welded pipe , hfi-erw pipe | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

|

OD |

W/T |

||

|

inch |

mm |

inch |

mm |

|

2-7/8 |

73 |

0.109-0.188 |

2.77-4.78 |

|

3-1/2 |

88.9 |

0.109-0.216 |

2.77-5.49 |

|

4-1/2 |

114.3 |

0.125-0.250 |

3.18-6.35 |

|

5-1/2 |

139.7 |

0.138-0.311 |

3.51-7.90 |

|

5-6/9 |

141.3 |

0.138-0.311 |

3.51-7.90 |

|

6 5/8 |

168.3 |

0.138-0.335 |

3.51-8.51 |

|

7 |

177.8 |

0.138-0.354 |

3.51-8.99 |

|

7-5/8 |

193.7 |

0.138-0.354 |

3.51-8.100 |

|

8-5/8 |

219.1 |

0.138-0.500 |

3.51-12.7 |

|

10-3/4 |

273.1 |

0.173-0.562 |

4.39-14.27 |

|

12-3/4 |

323.9 |

0.188-0.592 |

4.78-15.04 |

|

14 |

355.6 |

0.216-0.625 |

5.50-15.88 |

|

16 |

406.4 |

0.230-0.625 |

5.80-15.88 |

|

18 |

457.2 |

0.230-0.692 |

5.80-17.58 |

|

20 |

508.0 |

0.250-0.692 |

6.35-17.58 |

|

24 |

609.6 |

0.250-0.752 |

6.35-19.1 |

API 5L PSL1/PSL 2 Line Pipe: Gr. B X42, X46, X52, X56, X60, X65, X70, X80

ISO 3183 1/2/3 Petroleum and Natural Gas Industries – Steel Pipe for Pipelines-

DNV OS-F101 Submarine Pipeline Systems

DIN 17172 Stahlrohre fur Fernleitungen fur brennbare Flussingkeiten und Gase( Pipe for cross country pipelines for flammable liquid and gas)

ASTM A53 A/B

ASTM A211-85

ASTM A178/A214/A226 Gr. A

ASME SA211

ASTM A500

ASTM A252 FOUNDATION PILES for soil consolidation, marine wharfs,

AS1579

ASTM A-134

ASTM A-139 CHIMNEYS AND VENTILATION DUCTS for air and dust filtering systems, and smoke evacuation,PILLARS for ski chair-lifts and bridges

ASTM A513

AWWA C-200

CAN/CSA Z245.1

BS2059 Part I & II Gr. 320, Gr. 360

BS 3601 Gr. 430, Gr. 360

DIN 1626/2458-DIN 2470 Part 1 St. 37.0,St44.0, St.52.0

DIN1628 St. 37.4

DIN 17 172-DIN 2470 Part II St. E210-7, E240-7,E290-7, St. E 320-7,St.E 360-7

DIN 171777 St. 37.8, St. 42.8

EN 10208-1/97

EN 10208-2/96 + AC/96

EN 10219-1/97

GOST 10705/10704 GOST 1050-08SP, 10SP, 20SP

GOST 19282 09G2S

JIS G 3444

JIS G 3445

JIS G3452

STN 42 0144

STN 42 5738

UNI 8488

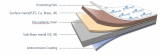

Coating Specifications:

Epoxy Coating: DIN 30670, CAN/CSA Z245-M92

Fusion Bonded Epoxy Coating: AWWA C213

2LPE/3PE Coating: DIN 30670, CAN/CSA Z245, TS 5139, NFA A49-710 UNI 9099

Polyurethane Coating: BS 5493

Lining: AWWA C210, TS 5140

ISO/DIS 21809-1, Petroleum and natural gas industries -- External coatings for buried or submerged pipelines used in pipeline transportation systems - Part 1: Polyolefin coatings (3- layer PE and 3- layer PP)

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Hoffman Fang

- Address

- Unit L, Fl. 5, Liaoshen International Plaza, 1068 Wuzhong Road, Shanghai, 201103 China

- Product Category

- Home & Kitchen,Industrial Supplies,Machinery & Parts

- No. of Total Employees

- 51-100

- Company introduction

-

Metals International Limited is a worldwide leading company specializing in all kinds of pipes and steel products.

We sold 40,000 metric tons of API X70 PSL 2 24" ERW line pipe (the first and highest ERW line pipe ex-China) & 20,000 metric tons of API 5L X52 40"/48" DSAW/LSAW line pipe for Ambatovy Project, Madascar, 105,000 metric tons of spiral welded line pipe (one of the biggest line pipe order ex-China) for New Skikda LNG Project, Algeria ,1200 metric tons of ASME SA213 T11/T22 38.0mm Boiler Tube (one of the biggest boiler tube order ex-China) for Austria Boiler Project, as well as an agent to supply 200,000 metric tons of API 5L X70 PSL 2 42" UOE DSAW line pipe(the first and highest UOE LSAW line pipe ex-China)for QGC LNG Pipeling Project, Australia,and other various steel pipes. With consistent strategic policy and continuous growth, Metals International has emerged out as a prominent player in the league of world-class corporation of steel pipes in the Global market. The organization has been expanding, integrating and growing at the speed of light the fulfill the ambition of its Global excellence. The establishment of Shanghai office had been a major milestone in the path of progress of the Group. Company is committed to quality products and also treasures its employees who make it happen. Its vast organizational strength comprises of dedicated and skilled teammates whose core competence lies in making a good products, a better one. Our product are in compliance with quality control at every manufacturing stage in accordance with API-5L, API-5CT, API 5LC,API 5D, API 5H ASTM, ASME, BS,EN,DIN, JIS, ISO, GOST,NFA,NACE,DNV-OS-F101 quality standards. They are also approved by international Third Party Inspection authorities like DNV, BV,SGS, Moody International, TUV, LR,GL,PED,RINA,KR,AIB-VINEOTTE,CEIL,VELOSI, CCSI, etc. Our goal is to provide quality products to our customers at competitive prices with best service that will ensure long-term relationships with our customers.

The following products mix are available:

Carbon Steel Pipe

(1) Welded Pipe: l UOE/JCOE Longitudinal Welded Pipe (LSAW/DSAW) , l Electric Resistance Welded Pipe (ERW), l Casing Pipe, l Helical/Spiral Welded Pipe (HSAW/SSAW) l Black/Galvanized Iron Tube l Hollow Structural Section(SHS/RHS) l Structural Pipe and Piling (2) Seamless Pipe: l Line Pipe l Oil-Well Tubing l Oil Country Tubular Goods (OCTG), l Alloy Pipe l Low-Medium-High Pressure Tubes, l Oil Cracking Tube, Boiler Tuber l Oil Tube l Heat Exchanger and Condenser Tube l Super-heater Tube l Flowline Tube l Chemical Fertilizer Tube l Bearing Tube l U-Tube l Inner Ribbed Tube l Mechanical Tube l Structural Pipe l Cylinder Pipe l Hydraulic Pressure Supporting Pipes l Pressure Vessel Pipe l Pipe for Ships l Cold Rolled/Drawn Tube l Hot-Rolled Tube/Pipe l Hot-Finished Pipe l Hot-Expanded Pipe Stainless Steel Pipe

(1) Welded Pipe: l Electric Fusion Welding Pipe (EFW) l UOE Longitudinal Welded Pipe

(2) Seamless Pipe: l Low-Medium-High Pressure Tubes l Oil Cracking Tube, l Boiler Tube l Low-Medium-High Pressure Tube l Oil Tube l Flowline Tube l Chemical Fertilizer Tube l Mechanical Tube l Structural Pipe l Hot-Extruded Tube l Evaporator Tube l Nuclear Power Tube l Super Critical Tube l Super Superheater Tube External Coating Epoxy Coating : AWWA C-210,NFA 49709,EN 10289 Polyethylene Coating : DIN 30670,NFA 49710 Polypropylene Coating : DIN 30678,NFA 49711 Bitumen Coating : DIN 30673,BS 534 Coal-tar Enamel Coating : AWWA C-203 Lining Epoxy Lining : AWWA C-210,NFA 49709,TS EN 10289 Bitumen Lining : DIN 30673 ,BS 534 Cement Mortar Lining : AWWA C-205, BS 534 Steel Products: (1) Flat Products: l Corrosion Resistance Steel Plate l Structural Steel Plate l Alloy Structural Steel Plate l Ship-Construction Steel Plate l Bridge Construction Steel Plate l High Strength Steel Plate l Pressure Vessel Steel Plate l Stainless Steel Plate (2) Strips/Coils: l Cold Rolled Strips/Coils l Hot Rolled Strips/Coils l Color-Coated Strips/Coils l Galvanized Strips/Coils l Stainless Steel Strips/Coils (3) Long Products: l U-Beam l Wire Rods l Debar l Rebar l Channel l Angle Pipe Fittings: (1) forged fitting & Self reinforced outlets Elbows, tees, crosses, couplings, half couplings, plugs, caps, bushings, unions, reducing inserts, hexagonal, straight and swage nipples with socket weld or threaded ends, butt weld outlets, socket outlets, threaded outlets, elbow, nipple and lateral outlets according to ASTM, ASME, UNI, DIN, ANSI, MSS SP standards.

Material used: carbon steel, alloy steel, austenitic and austenitic-ferritic steels, titanium. Main material codes and main dimensional standards applied: ASTM A 105, A 181, A 182, A 350, A 694. Steel grades: F5, F9, F11, F22, F304, F304L, F316, F316L, F321, F44, F51,

F42, F52, F60, F65, UNS N08800, UNS N08825, UNS N08925, UNS C70600. Dimensions according to ANSI B16.11, BS3799. For self reinforced outlets design calculations are carried out according to ANSI/ASME B31.1 or other Client specifications Compression fittings

Unions: reducing union, bulkhead union, union elbow, union tee, union cross, male connector, male thermocouple connector, male elbow, male run tee, male branch tee, female connector, gauge connector, female bulkhead connector, female elbow, female run tee, female branch tee, male adaptor, female adaptor, tube end reducer, tube end bulkhead adaptor, eye banjo couplings, non return valves, shut-off valves, ball valves, control needle valves, fittings for plastic hose for process control and instrumentation. Material used: carbon steel, stainless steel, brass. Main material and dimensional standard applied: ASTM A105, A479, tp 316, A182 F316, B16 alloy 360,

B453 alloy 345, B124 alloy 377. Dimensions acc. manufacturer standard, BS 4368 part 3; thread according ANSI B1.20.1, BS 3643, ISO 261, ISO 262. (2) Butt weld fittings

Seamless: Elbows and bends, short and long radius, bends (made by cold forming, hot forming in dies or by hot induction method), tees, caps and reducers up to 36” diameter according to ASTM, ASME, MSS SP 75, UNI, DIN, ANSI Standards. Welded: Elbows and bends, short and long radius, tees and reducers up to 72 inch diameter, bends (made by hot induction method up to 48 inch diameter). Larger diameters can be produced in mitered execution. Type of materials supplied: carbon steel, alloy steel, austenitic steel, ferritic-austenitic steel, titanium, copper, monel, inconel, hastelloy, incoloy. Main material codes and main dimensional standards applied:

ASTM A 234, A 403, A 420, A 815, B 363, B 366. Steel grades: WPB, WPL6, WP11, WP12, WP22, WP 304, 304L, WP316, 316L, WP 321, UNS S31803, UNS S31550, UNS S32750, UNS S32760, UNS S31254, UNS N06600, UNS N08800, UNS N08825, UNS N08925. MSS SP 75 WPHY 42, 52, 56, 60, 65.

Dimensions acc. ANSI B16.9, ANSIB16.28, MSS SP 43, MSS SP 75. Others: Lateral, saddles, sphere, tee, split tee and pigging tees designed according to customer requirements. (3) Flange: including carbon steels, low-temperature alloys, high-yield grades, stainless steels, super-stainless and exotic alloys. Our range of flanges includes the following: ·SAE flanges – 3,000lb and 6,000lb rated ·Plate flanges ·Rings and sockets ·Forged discs, caps and dished ends ·Long weld-neck flanges ·Seamless piped flanges ·Nozzles (with and without radius) ·Anchor flanges ·Compact flanges ·Swivel-ring flanges ·Customized flanges in line with customer specifications Flanges

Welding neck, slip-on welding, screwed, lapped, socket welding, blind, reducing, orifice, anchor and swivel ring type up to 78” according to ASTM, ASME, API, BS, UNI, DIN, ANSI, MSS SP 44, AWWA, TEMA. Material used: carbon steel, alloy steel, austenitic and austenitic-ferritic steels, titanium. Main material and dimensional standards applied: ASTM A105, A181, A182, A350, A694, B381. Steel Grades: F5, F9, F11, F22, F304, F304L, F316, F316L, F321, F44, F51, F42, F52, F60, F65, UNS N08800, UNS N08825, UNS N08925, UNS C70600, F2. Dimensions acc. to ANSI B16.25, ANSI B16.36, ANSI B16.1, API 605, API 6A, MSS SP 44, BS 3293, AWWA C207-55, ASME B16.47. Others : long welding neck, buttered flanges, weld overlaid flanges, spectacle blinds, blind and spacers, drip rings, stub ends, orifice plates, tube sheets, girth flanges, pieces according to client drawings or different international standards.etc. according to client drawings or different international standards. Valves

Globe, solid wedge gate, ball, butterfly, swing check, plug valves, manually or gear operated; with or without actuators and control panels. Valves can be supplied in carbon steel, alloy steel, stainless steel and other alloys. The main codes applied are ANSI B16.5 or ASME B16.47 for flanged ends, ANSI B16.34, API 600, API 6D, BS 5351Tel: +86-21-60900836/37

Fax:+86-21-60900838

- Main Markets

-

Argentina

Argentina

Australia

Australia

Bangladesh

Bangladesh

Belgium

Belgium

Brazil

Brazil

Cambodia

Cambodia

Canada

Canada

Chile

Chile

Colombia

Colombia

Ecuador

Ecuador

Egypt

Egypt

Finland

Finland

France

France

Germany

Germany

Hong Kong(China)

Hong Kong(China)

Israel

Israel

Italy

Italy

Kuwait

Kuwait

Madagascar

Madagascar

Mexico

Mexico

Myanmar

Myanmar

Netherland

Netherland

Norway

Norway

Oman

Oman

Philippines

Philippines

Portugal

Portugal

Russia

Russia

Saudi Arabia

Saudi Arabia

Singapore

Singapore

South Africa

South Africa

South Korea

South Korea

Switzerland

Switzerland

U. Kingdom

U. Kingdom

U.A.E.

U.A.E.

U.S.A

U.S.A

- Main Product

Related Products

clad steel(Ecoteel)

PVC/Vinyl Wire End Caps

Brushed PET film, Brushed foil, Hairline, laminating, VCM

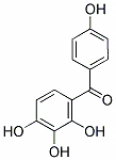

2,3,4,4'-Tetrehydroxybenzophenone, CAS NO.: 31127-54-5

Intermediate Crimped Wire Mesh