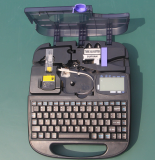

Conventional Plate Processor

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Printing Machines

McLantis Printing Equipments and Materials Group

- Verified Certificate

-

16

| Product name | Conventional Plate Processor | Certification | - |

|---|---|---|---|

| Category | Printing Machines | Ingredients | - |

| Keyword | plate processor , conventional plate processor , developpeuse de plaque , reveladora de placa | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Slant frame and durable PVC tank, acid and alkali proof. Corrosion-resist and anti-ageing rollers.

Precise Mitsubishi Control and Gear Driving System

Precise and reliable Mitsubishi PLC control panel. The main driving system lies in the left side of the plate processor. Gear driving assures of smooth driving and easy maintenance.

Water and Power Saving

Environmental-friendly washing mode - inner circle washing mode and tap water washing mode for option.

Submersion Developing and Automatic Process

Submersion developing structure ensures sufficient development. Automatic gumming, washing and gum recycle.

Rewash and Reverse Function

Rewash function makes it easy to wash and gum after revision of the plate. The reverse function eliminates plate jam and makes it easy to make emergency operation.

User Friendly and Easy Operation and Maintenance

The bearing seat is easy to be discharge for maintenance of roller to ensure durability. Compatible with automatic stacker and filtration system.

Driving System and Main Motor Wash Cycling System

Submersion Developing Structure Superior Quality Gear and Roller

Wire and Electronic Parts Control Panel

| Model | PROCEMAC | ||

| 90PC | 105PC | 120PC | |

| Material | positive and negative conventional PS plate | ||

| Capability | 400-1400mm/min | ||

| Width of Plate | 900mm | 1050mm | 1200mm |

| Depth of Plate | 0.15-0.4mm | ||

| Tank Content, dev | 24L | 35L | 40L |

| Tank Content, wash | 12L | 15L | 18L |

| Developing Temperature | 18-40 degree C (cooling system is optional) | ||

| Drying Temperature | 35-60 degree C | ||

| Developing Time | 15-40sec (from the inlet of plate to the outlet of plate) | ||

| Water Source | tap water, Min. water pressure 1 bar/15psi | ||

| Water Consumption | tap water 7L/min | ||

| Circulating water | 200ml per square meter | ||

| Diameter of Roller | 40mm | ||

| Diameter of Brush | 40mm | ||

| Speed of Brush | 90rpm | ||

| Developing Replenishment | 0-250ml per square meter | ||

| Developing Warm-up Time | from 18 to 40 degree C within 30min | ||

| Level Adjustment | adjustable | ||

| Power Supply | 50-60Hz 220V single phase 25A | ||

| Power | 3KW | ||

| Voltage Fluctuating Range | within 10% | ||

| Gross Weight | 220kg | 300kg | 400kg |

| Net Weight | 170kg | 255kg | 350kg |

| Packing Size(mm) | 1600×1500×550 | 1800×1700×750 | 2000×1950×950 |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- JM

- Address

- No.583 Jiaqian Rd, Nanxiang Hi-tech Park, Shanghai

- Product Category

- Printing Machines

- No. of Total Employees

- 51-100

- Company introduction

-

McLantis Printing Equipments and Materials Group is the biggest group of factories of printing equipments and printing press consumables. McLantis Group is started as a prepress solution provider by Shanghai McLantis Printing Technology Co.,Ltd and Shanghai Yaxing Printing Plates Factory. Till now McLantis Group has ten member companies, which covers pre-press itself, press, postpress and consumables. McLantis Group also establishes the long term strategic collaborations with more than 20 factories in manufacture, technology development, quality control and timely after sale service, etc.

McLantis has been supporting its customers worldwide for many years in the fields of printing industry. McLantis is the premier player in the production and distribution of high performance printing equipments and printing press consumables, including CTP platesetter, CTP plate processor, imagesetter, offset plate exposure, PS plate processor, film processor, offset plate register punch, plate baking oven, plate preserve machine, spray powder extraction system, fountain solution filter system, small size offset printing machine, paper cutting machine, die cutting machine, folding machine, laminating machine. McLantis material department also produces offset printing plate, conventional PS plate, CTP plate, printing blanket, printing ink. We also supply various printing consumables, including printing roller, underpacking paper, anti-marking paper, super blue net, dampening sleeve, compressed sponge, spray powder, die cutting rule, cutting stick, doctor blade, laminating film, hot stamping foil, stitching wire, hollow paper drill, hot melt glue, etc.

McLantis is owned by UK interests and prides itself on an integrated approach to operations in mainland China. We fully understand the international standards inline with standard printing work. Coupled with this, after years of experience, we have established a solid groups of production bases in China and a unique understanding of international printing market.

China Manufacturing

McLantis’s long experience of manufacturing operation in China means we know which goods China makes competitively to international standards.

Worldwide Distribution

With our group of factories in mainland China, we establish long-term strategic relationships with overseas customers to supply them cost-saving goods from China, while maintaining their quality standards.

- Main Markets

-

Australia

Australia

Chile

Chile

Germany

Germany

Hungary

Hungary

Iran

Iran

Malaysia

Malaysia

Mexico

Mexico

Turkey

Turkey

U.A.E.

U.A.E.

U.S.A

U.S.A

Venezuela

Venezuela

- Main Product

Related Products

Laminating Film

Vjet®1020 Thermal Inkjet Coder

Supvan TP76E tube printer, cable id printer, wire marking

Heavy Duty Pouch Laminator TOFO 330R6

Refrigerated Heating Bath Circulators - P

China

China