X Ray Film Processor

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Printing Machines

McLantis Printing Equipments and Materials Group

- Verified Certificate

-

16

| Product name | X Ray Film Processor | Certification | - |

|---|---|---|---|

| Category | Printing Machines | Ingredients | - |

| Keyword | film processor , x ray film , medical film processor , procesadora medical x ray | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | 844230 |

Product Information

۰Accurate ManufacturingIn the view of maintenance, the pedestal can be taken out easily when developing, fixation and drying as well as small volume and light weight. Meanwhile, the processor can use water to wash. The electric components are installed down dark box and can be maintained easily after uncapping.

PVC cylinder body compound mould with high temperature endurable and corrosion resistance and it is durable. The close-down side board is convenient to maintain. The metal components use stainless steel of Germany standard 316L to process accurately.

۰Liquid Display

Liquid display, microcomputer control, digital adjust each data of wash process. It can replace traditional stimulation adjustable, which make temperature, speed more intuitiosnic, more accurate. It installs several inspection systems, which can inspect each work state and show alarm when finding fault.

۰Simple Operation

Temperature adjustable and speed by using knob. It depends on sensor of transmission film to complete developing, fixation, wash and drying automatically.

۰Economic and Hi-efficiency

The design of cover board for developing and fixation can protect liquid from crossed pollution. It can prevent liquid from autoxidation and prolong the using time of liquid.

۰Accurate Conformation of Pedistal Transmission Film

The conformation for developing, fixation, wash and drying are compact, the combined parts use imported materials to mould. Roller use Dopount macromolecule compound material for corrosion resistance and high temperature endurable. Drying uses the design of jet flow air duct, which can ensure that there should not be any problem of blocking fiche, scoring.

۰Convenient Maintenance

In the view of maintenance, the pedestal can be taken out easily when developing, fixation and drying as well as small volume and light weight. Meanwhile, the processor can use water to wash. The electric components are installed down dark box and can be maintained easily after uncapping.

Processor with Desk Inside Structure

Micro Computer Controller Operation Panel

Drain and Cycling System Chemical Tank Cover

Film Feed Frame Side Cover

|

Model |

PROCEMAC |

|||

|

14XM |

14XA |

17XM |

17XA |

|

|

Operation |

manual |

automatic |

manual |

automatic |

|

Minimum Film Size (cm) |

10 X 10 |

10 X 10 |

10 X 10 |

10 X 10 |

|

Maximum Film Size (cm) |

35 X 43 |

35 X 43 |

43 X ∞ |

43 X ∞ |

|

Processing Time (sec) |

105, 135,165 |

90-360 |

105, 135,165 |

90-360 |

|

Processing Capacity (sheet/hour) |

80 (35 x 43) |

90 (35 x 43) |

110 (35 x 43) |

150 |

|

Developing Temperature |

20-40 degree C |

|||

|

Fixing Temperature |

20-40 degree C |

|||

|

Washing Temperature |

normal temperature |

|||

|

Drying Temperature |

20-70 degree C |

|||

|

Replenishment (ml/sqm) |

50-200 |

50-200 |

50-500 |

50-500 |

|

Medicine Tank Capacity (L) |

5.2 |

5.2 |

8 |

8 |

|

Water Consumption |

2 L/min |

|||

|

Dimension (cm) |

77 x 59 x 42 |

77 x 59 x 42 |

78 x 69 x 45 |

78 x 69 x 45 |

|

Weight (kg) |

70 |

70 |

100 |

100 |

|

Power |

220V/50HZ |

|||

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- JM

- Address

- No.583 Jiaqian Rd, Nanxiang Hi-tech Park, Shanghai

- Product Category

- Printing Machines

- No. of Total Employees

- 51-100

- Company introduction

-

McLantis Printing Equipments and Materials Group is the biggest group of factories of printing equipments and printing press consumables. McLantis Group is started as a prepress solution provider by Shanghai McLantis Printing Technology Co.,Ltd and Shanghai Yaxing Printing Plates Factory. Till now McLantis Group has ten member companies, which covers pre-press itself, press, postpress and consumables. McLantis Group also establishes the long term strategic collaborations with more than 20 factories in manufacture, technology development, quality control and timely after sale service, etc.

McLantis has been supporting its customers worldwide for many years in the fields of printing industry. McLantis is the premier player in the production and distribution of high performance printing equipments and printing press consumables, including CTP platesetter, CTP plate processor, imagesetter, offset plate exposure, PS plate processor, film processor, offset plate register punch, plate baking oven, plate preserve machine, spray powder extraction system, fountain solution filter system, small size offset printing machine, paper cutting machine, die cutting machine, folding machine, laminating machine. McLantis material department also produces offset printing plate, conventional PS plate, CTP plate, printing blanket, printing ink. We also supply various printing consumables, including printing roller, underpacking paper, anti-marking paper, super blue net, dampening sleeve, compressed sponge, spray powder, die cutting rule, cutting stick, doctor blade, laminating film, hot stamping foil, stitching wire, hollow paper drill, hot melt glue, etc.

McLantis is owned by UK interests and prides itself on an integrated approach to operations in mainland China. We fully understand the international standards inline with standard printing work. Coupled with this, after years of experience, we have established a solid groups of production bases in China and a unique understanding of international printing market.

China Manufacturing

McLantis’s long experience of manufacturing operation in China means we know which goods China makes competitively to international standards.

Worldwide Distribution

With our group of factories in mainland China, we establish long-term strategic relationships with overseas customers to supply them cost-saving goods from China, while maintaining their quality standards.

- Main Markets

-

Australia

Australia

Chile

Chile

Germany

Germany

Hungary

Hungary

Iran

Iran

Malaysia

Malaysia

Mexico

Mexico

Turkey

Turkey

U.A.E.

U.A.E.

U.S.A

U.S.A

Venezuela

Venezuela

- Main Product

Related Products

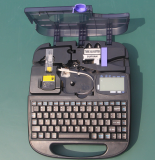

Supvan TP76E tube printer, cable id printer, wire marking

Retort pouch

Heidelberg Kord 64 Offset Paper Printing Machinery

Vjet®1020 Thermal Inkjet Coder

3d film for Sublimation

China

China