Alumina ring advanced technical ceramics

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Ceramics

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

- Verified Certificate

-

12

| Product name | Alumina ring advanced technical ceramics | Certification | - |

|---|---|---|---|

| Category | Ceramics | Ingredients | - |

| Keyword | advanced ceramics , ceramic ring , technical ceramics , technical ceramic ring | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

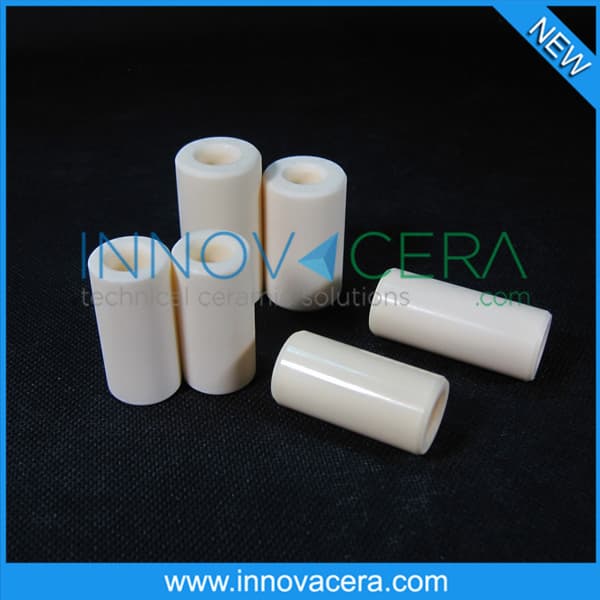

Wear resistant/Alumina/ceramic insulator roller/ring as technical ceramics/innovacera

Keywords: alumina ceramics, ceramic ring, alumina ring, ceramic insulator ring, ceramic ring, ceramic insulator

1. Introduction:

Alumina ceramic is the most mature of the engineering ceramics, offering excellent electrical insulation properties together with high hardness and good wear resistance but relatively low strength and fracture toughness.

Alumina is an electrically insulating material, with a high electrical resistivity, increasing with purity.

The alumina material is unique in that it does not expand, even at high temperatures. Components made of this material can withshand even the most abrupt temperature changes of several hundred degrees without damage.

These properties make aluminum titanate especially ideal for use in metallurgical melting, Components for furnaces, Thermocouple tubes, Machine components.

2. Alumina ceramics features:

1).Excellent electrical insulation

2).High hardness

3).Relatively low strength and fracture toughness

4).Resistance to wear and corrosive

5).Excellent thermal stability

6).Resistance to high temperatures

7).High electrical resistivity

8).Good chemical stability and resistance

9).High corrosion resistance

10).Excellent thermal shock resistance

11).High thermal insulation

12).A Low Young's modulus

3. Properties of Alumina Material

| Properties | Units | Alumina(Al2O3) | ||||||

| Porous | Mullite | Al2O3 92% |

Al2O3 96% |

Al2O3 99% | Al2O3 99.5% | |||

| Al2O3 | ||||||||

| Mechanical | Density | g/cm3 | 2.8 | 3.6 | 3.7 | 3.9 | 3.9 | |

| Color | —— | —— | Tan | White | White | Ivory | Ivory | |

| Water Absorption | % | 0 | 0 | 0 | 0 | 0 | ||

| Vickers Hardness | Gpa | —— | 7.4 | 11 | 11.5 | 13 | 14 | |

| Flexural Strength (20°C) | Mpa | 50~100 | 170 | 345 | 358 | 380 | 380 | |

| Compressive Strength (20°C) | Mpa | 20~100 | 550 | 2200 | 2300 | 3000 | 3000 | |

| Thermal | Thermal Conductivity (20°C) | W/m.K | 3.1 | 3.5 | 16.7 | 24.8 | 25~35 | 25~35 |

| Thermal Shock Resistance (20°C) | ΔT(C) | —— | 300 | 250 | 250 | 200 | 200 | |

| Maximum Use Temperature | °C | 1900 | 1700 | 1500 | 1600 | 1700 | 1700 | |

| Electrical | Volume Resistivity (25°C) | Ω.cm | —— | >1014 | >1014 | >1014 | >1014 | >1014 |

4. We can supply the products according to customer's drawings, samples and performance requirement. Welcome to send your inquiry for us at any time.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Mr. Qiu

- Address

- Room 615, NO.398 Jiahe RD, Huli District, Xiamen, Fujian, China 361006

- Product Category

- Ceramics,Electroceramics

- Company introduction

-

As a manufacturer of technical ceramic products, Innovacera main business is producemetallization ceramics and ceramics components as customer request. Innovacera offer you a wide range of production facilities like extrusion, injection moulding, pressing and casting. Depending on product geometry and quantities, we will choose the suitable technique for your products. For the final finishing of the parts we use CNC machining centres, equipped with diamond tools in order to meet high accuracies. Ceramic materials offer unprecedented possibilities for many industries, especially when products and components with extreme material properties are required. ceramic material including Aluminium Oxide, Zirconium Oxide, Silicon Carbide, Boron Carbide, Silicon Nitride and Boron Nitride. Innovacera products widely used in Aerospace, Research, Food Processing, Fluid Handling, Scientific, Automotive, Defense, Thermal Processing, Electrical, Process Control, Textile & Wire, Pulp & Paper, Mechanical, Glass Processing, Mineral Processing as well as smaller niche markets. Our aim is to offer the ideal solution for any application. Our engineers therefore offer custom solutions that range beyond our existing product portfolio. With our well-equipped industrial development facilities, we produce innovations that can be rapidly commercially exploited.

- Main Product

Related Products

Ceramic Fiber Paper

Computer scrap

Ceramic fiber blanket

Ceramic Fiber Textiles

Hot Pressed Hexagonal BN Boron Nitride Ceramic Crucible

China

China