QTJ Series compact structure brick machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- SHENTA Brick Machine

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

GUANGXI SHENTA MACHINERY EQUIPMENT CO.,LTD

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

11

| Product name | QTJ Series compact structure brick machine | Certification | - |

|---|---|---|---|

| Category |

Other Machinery Parts

Construction Material Making Machinery Other Construction Machinery |

Ingredients | - |

| Keyword | brick machine , brick making machine , compact structure machine , concrete brick machine | Unit Size | - |

| Brand name | SHENTA Brick Machine | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Main Specification:

|

Model |

QTJ4-18 |

QTJ5-20 |

|

Pallet size (mm) |

840x450x30 |

1050x550x30 |

|

Operation cycle |

15~25s |

15~25s |

|

Forming method |

Gravity Press + Table vibration |

Gravity Press + Table vibration |

|

Forming Height (mm) |

60~200 |

60~200 |

|

Power source (Kw) |

37 |

44 |

|

Mixer Model |

JS400 |

JS400 |

|

Dimension |

5500x2800x4300 |

5600x3000x4300 |

|

Net Weight (ton) |

7 |

8 |

Theoretical Productivity:

|

Brick Model |

QTJ4-18 |

QTJ5-20 |

||

|

Blocks/Pallet |

Blocks/day (8h) |

Blocks/Pallet |

Blocks/day (8h) |

|

|

390x190x190mm Hollow Brick |

4 |

~6,000 |

5 |

~7,000

|

|

390x150x190mm Hollow Brick |

5 |

~7,000 |

6 |

~8,500

|

|

390x100x190mm Hollow Brick |

7 |

~10,000 |

9 |

~13,000

|

|

240x115x53mm Solid Brick |

21 |

~33,000 |

32 |

~46,000

|

Characteristic

Control system: Adopted with Taiwan intelligent programmable logic controller (PLC) and high performance LCD, our brick machines can realize the man-machine conversation and fully automatic intelligent operation.

High efficient vibration system: Adopt intelligent control and synchronous vertical vibration techniques. Bricks formed by synchronous vibrations of press head and mould table, which makes the forming speed faster and the bricks denser.

Machinery Manufacturing: Made of high strength steels according to the national standard. Special welding techniques and advanced mechanical working processes bring high precision, durable and a long service life.

Transmission system: Adopted with mechanical transmission and two pillars oriented. Simple and compact structure brings it stable and consecutive actions and easy to be maintained.

Feeding system: Adopt the forced advanced rotating arch breaker. It is suitable for various materials, and the process is uniform and quick.

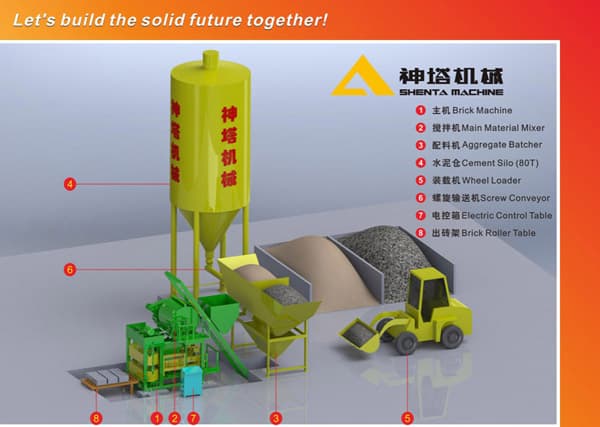

Production Line Layout:

Brick Sample:

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

GUANGXI SHENTA MACHINERY EQUIPMENT CO.,LTD

- Country / Year Established

-

China

/

China

/

- Business type

- Others

-

11

- President

- Mrs.Sherry

- Address

- No. A-6-1 Pingshan Er Road, Mingyang Industry Zone, Nanning, Guangxi

- Product Category

- Concrete Machinery,Construction Material Making Machinery,Other Construction Machinery

- No. of Total Employees

- 101-500

- Company introduction

-

Guangxi SHENTA Machinery Equipment Co., Ltd is the earliest plant specialized in manufacturing brick making machine and concrete block molding machine in China and is concentrated on integration comprehensive solutions of research and development, manufacturing, selling and technology service of block making machine. Our company provides products including automatic concrete production line, semi-automatic production line and economic block production line, JS serires concrete mixer and STH series Mini. Mobile concrete mixer

- Main Markets

-

Argentina

Argentina

Australia

Australia

Brazil

Brazil

Indonesia

Indonesia

Malaysia

Malaysia

Myanmar

Myanmar

South Korea

South Korea

U.S.A

U.S.A

- Factory Information

-

GUANGXI SHENTA MACHINERY EQUIPMENT CO.,LTD

- Main Product