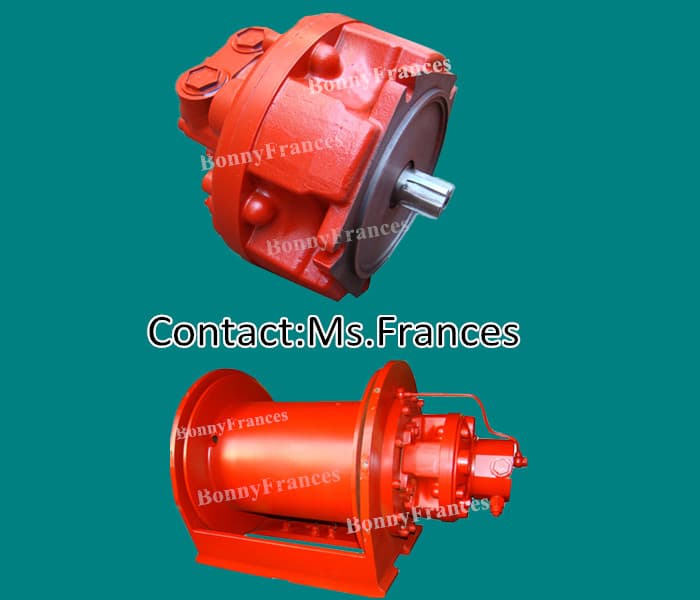

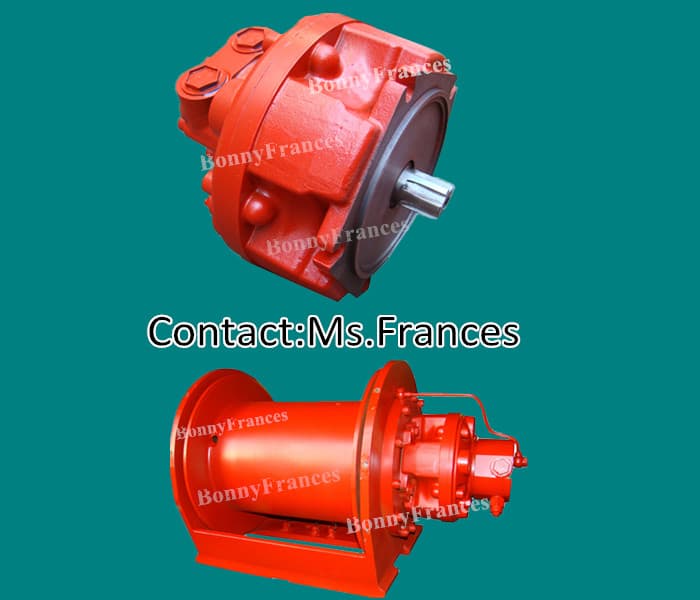

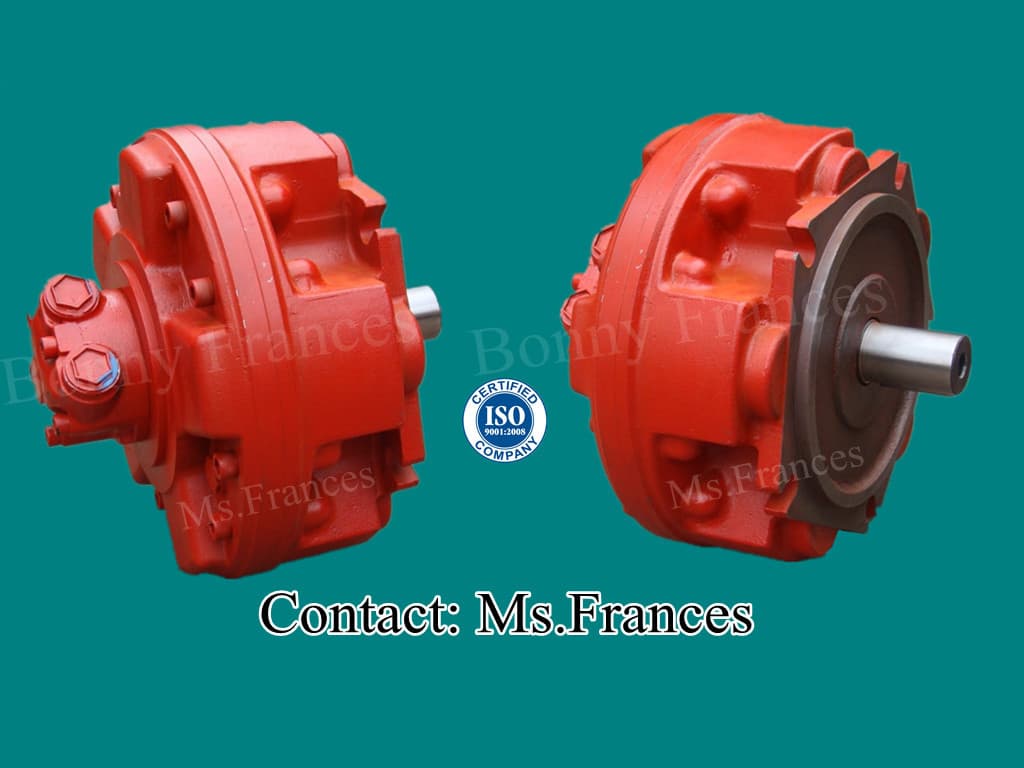

GM1 radial piston hydraulic motor for winch

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- frances(at)bonnyhydraulic(dot)com

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- hydraulic winch motor, low speed high torque hydraulic motor, radial piston hdyraulci motor, sai gm piston motor

- Category

- AC Mortor

Ningbo Bonny Hydraulics Transmission Co.,Ltd

- Verified Certificate

-

12

| Product name | GM1 radial piston hydraulic motor for winch | Certification | - |

|---|---|---|---|

| Category | AC Mortor | Ingredients | - |

| Keyword | hydraulic winch motor , low speed high torque hydraulic motor , radial piston hdyraulci motor , sai gm piston motor | Unit Size | - |

| Brand name | frances(at)bonnyhydraulic(dot)com | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | 841229 |

Product Information

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Frances

- Address

- 36, 3rd Road of Dagang, Beilun, Ningbo, Zhejiang, China

- Product Category

- Gearboxes,Motor Accessories,Winches

- Company introduction

-

we are the manufacturer of hydraulic motor, hydraulic winch, final drive and tracked undercarriages.

1. Hydraulic Motor

Interchanged with:

SAI GM Series, Intermot NHM Series, Poclain MS Series, Rexroth A2FE, A2FM, A6VE, A6VM Series, Sauer Danfoss OMP, OMR, OMS, OMT Series, Eaton, White, Eaton and Char-lynn orbital motor

2. Hydraulic Winch

Type: Hoisting hydraulic winch

Hydraulic recovery winch

Free fall hydraulic winch (Pulling hydraulic winch)

Application: Hydraulic mobile crane, pick n carry crane, overhead working truck, lorry mounted crane, mirror crane, drilling rig, piling machine, Ship, and truck

Interchanged with: Dinamic oil hydraulic winches (BH, NP, P, S, SE series), Brevini hydraulic winch (BW series)

3. Planetary Gearbox

Interchanged with: Bonfiglioli 300 series, Brevini ED, ET, EM, EQ, SL Series, Dinamic Oil RE, GB Series, Reggiana Ridduttori RRRR Series, FAIRFIELD planetary gearboxes (FAIRFIELD W series)

4. Tracked Undercarriage

Type: Rubber tracked undercarriage

Steel tracked undercarriage

5. Final Drives

Interchanged with:

Rexroth GFT Series, Komatsu Final Drives, Bonfiglioli 600, Series, 700C Series, Dinamic oil wheel drives and truck drives, Brevinil wheel drives and track drives, FAIRFIELD track drive (FAIRFIELD CT SERIES), Antriebstechnik O&K track drives/ track motor/ final drive (Antriebstechnik O&K F, FA, FR series), Reggiana Riduttori RRRRTD TRACK DRIVES

6. Swing Drives

Interchanged with:

Rexroth GFB Series, Brevini RPR Series, Dinamic oil slewing gearbox, Bonfiglioli slewing gears (Bonfiglioli 700T Series), Antriebstechnik O&K Slewing gears (Antriebstechnik O&K S series), FARIFIELD slewing gears, Reggiana Riduttori RR SLEWING DRIVES

7. Winch Drives

Interchanged with: Rexroth GFT-W Series winch drives, Bongfiglioli winch drives (Bonfiglioli 800 series), FAIRFIELD winch drives

8. Wheel drives

Interchanged with: Dinamic oil wheel drives, Bonfiglioli wheel drive (Bonfiglioli 600 series),

FAIRFIELD wheel drive (FAIRFIELD S SERIES wheel drives), Reggiana Riduttori RRRRWD WHEEL DRIVESContact Name:Frances

Cell:0086-18758373076

- Main Product

Related Products

RS-555PH Micro DC motor

Electronic Motors (SSM-16HR)

AC Induction /speed control Motor

Doorlock Motor (SRM-27H)

DC 12/24V Transom Mounted Electric Outboard Motor

China

China