Inert Alumina ceramic ball manufacturers

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- RISING

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Industrial Supplies

Shenzhen Rising Technology Co.,Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

11

| Product name | Inert Alumina ceramic ball manufacturers | Certification | - |

|---|---|---|---|

| Category | Industrial Supplies | Ingredients | - |

| Keyword | alumina ceramic ball , ceramic packing , alumina machining , ceramic support balls | Unit Size | - |

| Brand name | RISING | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

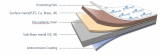

Inert alumina ceramic balls are widely used in oil refining and petrochemical, chemical, fertilizer, natural gas chemical, environmental protection industries, as the catalyst supporting and covered material inside the reactor ,it can buffer the impact of incoming process media on the catalyst, playing a role of protecting the catalyst and improving the process media of distribution function.

Specifications:

Physical and chemical properties

Note: It may only be provided as the reference for the bulk density, and it is not as the evidence of check.

Chemical Compositions

Specifications and types

1.Assortments

In accordance with the content of inert Al2O3 from 25% to 99%, there are 18 assortments on every 5% as a grade.

2. Specifications and allowable deviation of diameters

The product of other specifications can also be prepared according to customers' requirement.

Notice to ordering goods.

1. As the inert ceramic ball belongs to the natural tight stacking in the reactors, please you should consult with our technological staff to determine the amounts according to the practical loading volume, and remain 15-20% margins

2. Please you provide the specification, types, and the total content of Si, Al related to the required product.

3. When ordering our goods, please you should introduce the radical situations of the equipment, including the sizes of reactors, and the operational temperature etc.

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Mark Lei

- Address

- 16F, Block B, Fortune Plaza, Futian, Shenzhen, Guangdong, China

- Product Category

- AdsorbentMolecular Sieves,Catalyst & Chemical Auxiliaries,Industrial Supplies

- No. of Total Employees

- 101-500

- Company introduction

-

Shenzhen Rising Technology Co.,Ltd., is a professional production manufacturer of reformate catalyst , chemical packing and alumina ceramic industrial company. we has the most experienced and the exquisite technical experts and team in the field of catalysts and industrial ceramic production technology, has been in the China leading position in the product research and development, production process, test level. We have been the qualified supplier of China Petrochemical, China PetroChina and CNOOC for 15 years. Our main products are reformate refined catalyst, activated alumina, ceramic ball, random and structured chemical packing in ceramic, plastic tower packing, honeycomb ceramics, molecular sieves wear-resisting ceramic ball, wear-resisting alumina lining plate. The company has the advanced materials handling system, strictly perfect raw material and product testing system, scientific first-class production process system, and customer service system , and the fulfillment of the operating principles of “ faithful , careful, efficient, and practical ” ,Products are widely used in chemical, oil refining, metallurgy, electric power, environmental protection industries . Our latest research and development products: Reformate Refined Catalyst can replace the activated clay and remove the olefins trace in reformate. It also can prevent the poisoning subsequent PX adsorbent and disproportionate catalyst. Catalyst’s single cycle life is more than 10 times of clay. In addition , solid waste emissions rate dropped by more than 85- 90%.The catalyst can be used repeatedly by regeneration 3 or 4 times , as well as it can reduce the clay change frequency and severe pollution of environmental pressure.

- Main Markets

-

Canada

Canada

Germany

Germany

India

India

Italy

Italy

Japan

Japan

North Korea

North Korea

U.S.A

U.S.A

- Main Product