CM CENTRIFUGAL DUST COLLECTOR

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- BLACK HOLE

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- collector, dust collector, duster

Myungjin Machinery Ind. Co., Ltd

- Verified Certificate

-

11

| Product name | CM CENTRIFUGAL DUST COLLECTOR | Certification | - |

|---|---|---|---|

| Category |

Machinery & Parts

Other Machinery & Industry Equipment Cleaning Brushes & Dusters |

Ingredients | - |

| Keyword | collector , dust collector , duster | Unit Size | - |

| Brand name | BLACK HOLE | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

WHAT IS CENTRIFUGAL DUST COLLECTOR?

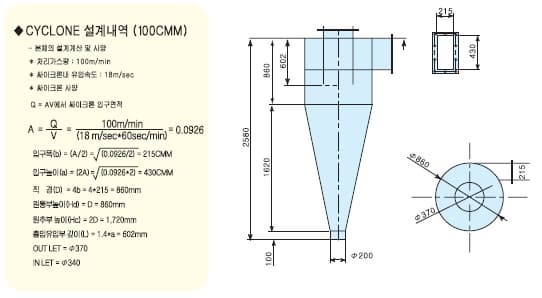

The Centrifugal Dust Collector is an apparatus precipitating and collecting the dust separating the particles from gases with centrifugal force providing rotating movement to those thick particles with high gravity.

As for the dusts with large particles, the dust collector is a sort of cyclone independently used demonstrating solid performance, and utilized as a pre-treatment facility for high efficiency dust collector for removing fine particles.

The pressure loss, primary element influencing on performance, having the dimension ratio, inlet condition and treatment speed work as variables.

The design of Centrifugal Dust Collector should consider the state of dust particles, displacement, inflow velocity, selection of blower and etc., which substantially influences the performance of dust collector.

TYPE OF COLLECTOR

1. Tangential Entry Type Cyclone

The Tangential Entry Type Cyclone induces the dirty gases flowing inside of external enclosure, as sorted by the overhead type, spiral winding type and etc. The velocity of in-flowing gas is in general 7~15m/sec., which shows relatively low interference on dust removing rate having the diameter of internal enclosure work as major element determining the performance.

The press loss, when the velocity of inlet gas reaches about 12m/sec, is around 100mmH2O with the overhead type, and about 20% lower pressure loss with the spiral winding type.

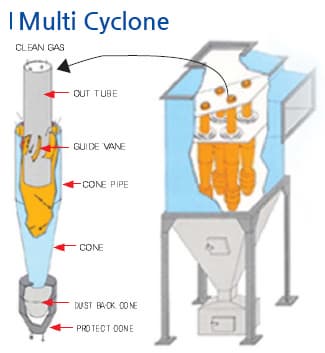

2. Axial Inlet Type Multi-cyclone

The Axial Inlet Type Multi-cyclone is used for the application where the amount of gas to be treated in massive requiring high dust collecting efficiency. The cyclone is composed of multiple, small diameter cyclones arranged in parallel aligning the treatment gas inlet in parallel with the centrifugal dust collector shaft. The gas to be treated flows in from the top section of dust collector generating and discharges outside of outlet with reversed rotation after flowing inside to the lower section, while activating the circulation of flow alongside the spiral guide kit installed at the inlet.

The Axial Type is capable of treating more gases approximately three times in comparison with other types of cyclones, and further, easy to distribute the dirty gases evenly to each of unit cyclones.

The velocity of inlet gas is about 12m/sec. with the pressure loss of around 70~80mmH2O.

FEATURES

- Treatment of hot gas applicable with less

pressure loss.

- Dry collection and removing of dust applicable

with low costs of operation and manufacturing.

- Simple maintenance and operation.

- Low dust collection efficiency. (Event of dusts

below 10µm)

- Complicated to treat the moist dusts.

- Sensitive to the variation with amount and flow of dusts.

APPLICATIONS

- Dust generated from boiler.

- Cement manufacturing and stone processing plants.

- Timber mill and Flour mill.

- Back-end facility of incinerator

- Pre-treatment facility

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Kim Hwang Ja

- Address

- 1663-5, Seongso 5th Industrial complex, Secheonri, Dasaeup, Dalsungkun, , Daegu, Korea

- Product Category

- Machinery & Parts,Machinery Parts Processing Services

- No. of Total Employees

- 1-50

- Company introduction

-

“BLACK HOLE” DUST COLLECTOR PRODUCTS offered by the Myungjin Machinery Ind. Co., Ltd. allow flexible custom designing as per the particular natures of jobsites, specific equipment characters, postures of operators and types of dusts involved. The employees and management of Myungjin Machinery Ind. Co., Ltd. are committed to present the satisfaction to customers with no simple portable collectors but custom manufactured dust collectors exactly fitting to each particular jobsite condition based on the technologies and trust accumulated to date for 26 years.

- Factory Information

-

MYUNGJIN

- Main Product

Related Products

Airless Pump (Ratio 63:1 Airless Pump)

NMB Bearing

NEMA17 42mm stepper motor with driver or controller

KBC Bearing

UIM2901-5A MACH3 break out board for CNC

South Korea

South Korea