Digital Protection Relay: PAC-M100 (Motor)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- PNC TECH

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- m100, motor, protection, relay

- Category

- Electrical Equipment , Passive Components

PNC TECHNOLOGIES CO., LTD.

- Membership

- VIP

- Recent Visit

- Jan 16, 2025

- Country / Year Established

-

South Korea

/

1999

South Korea

/

1999

- Business type

- Manufacturer

- Verified Certificate

-

17

| Product name | Digital Protection Relay: PAC-M100 (Motor) | Certification | - |

|---|---|---|---|

| Category |

Electrical Equipment

Passive Components |

Ingredients | - |

| Keyword | m100 , motor , protection , relay | Unit Size | - |

| Brand name | PNC TECH | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

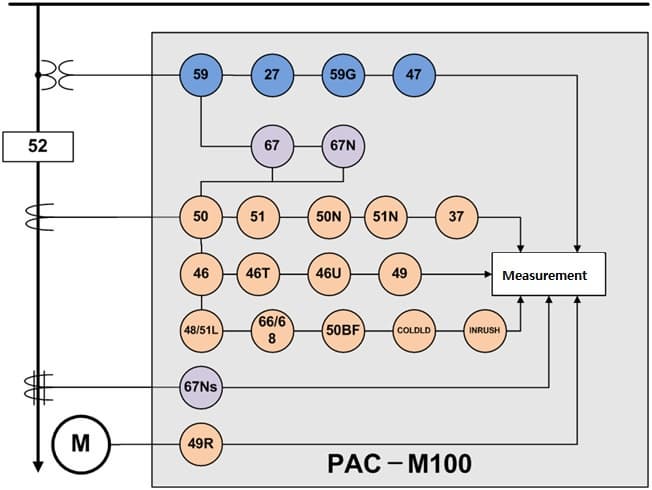

PAC-M100: Motor protection device

PAC-M100 has many functions such as protection,

control and monitoring. PAC-M100 can be used for motor protection and motor feeder

protection regardless the type or output power of the motor.

The protection components of PAC-M100 are phase/ground overcurrent, motor starting,

start inhibit for motor, thermal, negative phase sequence overcurrent, current unbalance,

phase under/over voltage etc. PAC-M100 has various electrical values measuring function

and monitoring function such as self-diagnosis, current input circuit, current/voltage

unbalance, PT fuse failure and Trip Circuit Supervision (TCS).

PAC-M100 has 4 independent setting groups for protection in order to change and apply

quick setting according to changing the power system load condition.

The programmable logic(EasyLogic) of PAC-M100 support economical solution for

configuring trip logic, inter-lock sequence and lock-out function without additional

hardwired logic or connection.

The Event and waveform recording function of PAC-M100 offer running history data and

fault analysis data. The event and waveform recording data are maintained in PAC-M100

even if control power is lost. The recording data can be analyzed by integration PC program

(PACManagerTM) after uploading through the front communication port of PAC-M100.

The MIN/MAX recording function of PAC-M100 records the quantity of electricity as a

primary value with occurring time. The recordings are maintained even if control power is

lost.

The front of PAC-M100 are 8 basic LEDs, user programmable LEDs, graphic LCD and key

pad. The operational keypad and high resolution graphic LCD makes it possible to manage

setting, monitoring and control function conventionally. There is one RS-232 port on front

of PAC-M100 for communicating with PC program (PACManagerTM) also.

At rear side of PAC-M100, there are two RS-485 ports for connect with remote monitoring

system. The RS-485 communication port supports ModBus, DNP3.0 and IEC 60870-5-103 protocols.

Features

Digital protective relay with two processors.

Protection of medium/high voltage asynchronous motor or motor feeder.

4 setting groups for protection components.

18 kinds of protection components : OCR, OCGR, SGR, Thermal Overload, UCR,

NSOCR, UBOCR, OVR, UVR, OVGR, NSOVR, CBF, STALL, START, PHS DIR,

GND DIR, COLD LD, INRUSH.

Various TC curves : IEC standard, ANSI standard, KEPCO induction type, P&C curve

CB open/close control at local and remote.

Metering functions : 3-phase current/voltage, Sequence current/voltage, 3 phase real

/reactive /apparent power, Energy, Frequency, Power factor, Thermal, THD(including

up to 31st harmonic), Demand current, Three phase demand real/reactive/apparent

power, Reclosing count etc,.

Event record up to 1024 and 8 fault waveform recording (64 samples/cycles)

The MIN/MAX recording of quantity of electricity : Line to line voltage,

Voltage/current by a phase, Three phase real/reactive/apparent power, Three phase

power factor, Demand current by a phase, Three phase demand real/reactive/apparent

power, Frequency etc.

Engineering tool : Setting of change, Event uploading, Fault waveform analysis

Graphic LCD (240 × 128, 16 lines × 30 characters) : Single line diagram, tree structure

menu, 16 LEDs, 11 Keypad buttons.

Communication port : 1 RS-232 port at front side (ModBus Protocol : Setting of

change, Event/Fault waveform transmission, measuring monitor), 2 RS-485 ports at

rear side(SCADA communication, DNP3.0/ModBus/IEC60870- 5-103 protocol)

Self-diagnosis function : DC power supply, Memory, CPU, Setting of range, DSP, A/D

converter, Analog input circuit, internal logic component and digital input/output

circuit.

5 monitoring functions : PT Fuse failure monitoring(PT Fuse failure), Current input

circuit monitoring(Current Sum), Voltage unbalance monitoring(Voltage Balance),

Current unbalance monitoring(Current Balance), Trip circuit (TCS) monitoring

function

8 user programmable LEDs.

EasyLogic for programming sequence logic.

Test function : Contact output, front panel display.

With ease upgrading firmware using flash memory.

Flexible control power (option : AC 110 ~ 240 V, DC 19 ~ 130 V)

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

PNC TECHNOLOGIES CO., LTD.

- Country / Year Established

-

South Korea

/

1999

South Korea

/

1999

- Membership

- VIP

- Recent Visit

- Jan 16, 2025

- Business type

- Manufacturer

-

17

- President

- NamSeon Yoon

- Address

- (Hogye-dong), 62, Jeonpa-ro 104beon-gil, Dongan-gu, Anyang-si, Gyeonggi-do, Korea

- Product Category

- Passive Components,Power Supplies,Remote Control Switches

- Year Established

- 1999

- No. of Total Employees

- 51-100

- Company introduction

-

Founded in 1999,

PNC Technologies Co., Ltd. is the leading Korean manufacturer in the field of electrical power industries, especially for Substation and Distribution Automation, Power Protection, Power Measurement, Communication and SCADA system.

We are preparing the future of power with state-of-the-art technology to fulfill the valuable customer's various needs.

- Main Markets

-

Greece

Greece

Indonesia

Indonesia

Oman

Oman

Saudi Arabia

Saudi Arabia

South Korea

South Korea

Taiwan

Taiwan

Thailand

Thailand

Turkey

Turkey

- Factory Information

-

PNC Technologies Co., Ltd

- Main Product

Related Products

Magnetic Contactor (MC)

3.7V Li-ion Battery Overcharging Protection Circuit Module

IP67 waterproof Terminal Block Box 4P Knock-out

Hi-Fix Board

Household Frequency Converter 50Hz 60Hz 2KW