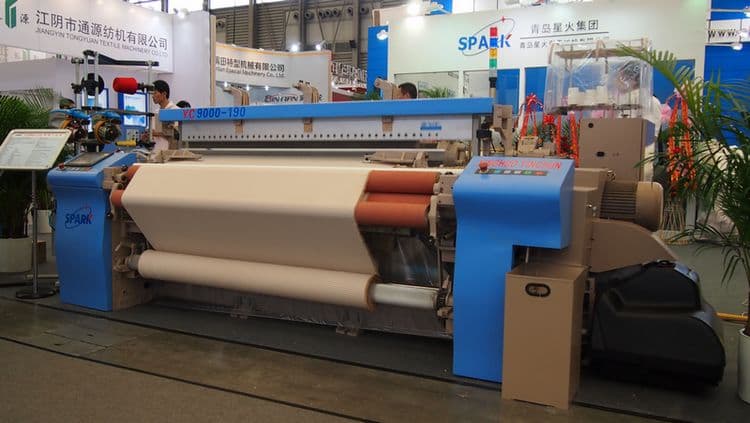

YC9000-190 Air jet loom with 2 nozzles

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- QingDao Spark Yinchun

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- air jet loom, loom, textile machinery, weaving machine

- Category

- Textile Machinery

Qingdao Saprk Yinchun Textile Machinery Co.,Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

11

| Product name | YC9000-190 Air jet loom with 2 nozzles | Certification | - |

|---|---|---|---|

| Category | Textile Machinery | Ingredients | - |

| Keyword | air jet loom , loom , textile machinery , weaving machine | Unit Size | - |

| Brand name | QingDao Spark Yinchun | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | 844630 |

Product Information

Air jet loom YC9000, adopting properly structure and stable box-type frame structure, high-precision CNC and integral welding beam with many auxiliary supporting frame in the middle, results in being equipped strictly with more stable and dependable rack, which can ensure the lesser vibration of 0.25m/s2 of the loom when weaving .Various beating systems are available for users which can realize four-bar, six-bar and conjugate cam beating. The solid beating shaft and multiple auxiliary supporting and counter weight balanced beating systems improve the stability of the loom at high speed operating. The loom is suitable for high-density weave and can improve the quality and efficiency. The new design of the air path of the supporting spray solenoid valve which integrates with flow cavity makes the air consumption decrease from the 1.2cub/min to 0.8cub/min which shortens the paths of air delivery to decrease the consumption of the air. Six-bar beating-up mechanism with abundant weft time on the steel reed improve the advantage during the width weaving to ensure the weft insertion.

|

AIR JET LOOM YC9000 MAIN TECHNICAL CHARACTERISTICS

|

|||

|

ITEM |

SPECIFICATION |

SPARE PARTS |

|

|

Reed width |

Nominal Reed width |

150,170,190,210,230,250,280,340,360,390cm |

|

|

Useful Reed width |

Nominal:0~-60cm(150~250) |

|

|

|

|

0~-80cm(>280) |

|

|

|

Weaving range |

|

Short yarn:Ne100-Ne2.5 |

|

|

Filament:22dtex-1350dtex |

|

||

|

Weft selection |

|

1,2,4,6 color |

|

|

Motor |

Start mode |

Super speed start motor |

|

|

Push-button start, stop, frontal/r slow move |

|

||

|

Push-button switch handed |

|

||

|

Motor power |

2.8Kw,3.0Kw,3.8Kw,4.5Kw |

|

|

|

Weft insertion |

Mode |

main nozzle+ swing nozzle +sub nozzle +abnormity lock |

Weft brake |

|

Control |

import high-frequency solenoid valve, computer program control |

|

|

|

Sub nozzle solenoid valve |

The supporting spray solenoid valve which integrates with flow cavity |

|

|

|

Measuring Weft storage |

electric control loop separated weft storage |

Ballooning prevention device |

|

|

Beating-up |

Beating-up motion |

Double side tank oil-bath type four-bar beating-up motion |

|

|

Double side tank oil-bath type four-bar beating-up motion |

|

||

|

Double side tank oil-bath type conjugate cam beating-up motion |

|

||

|

|

multi-sleysword solid beating-up warp and weft system |

|

|

|

|

multi-supporting base, balance weight |

|

|

|

shedding |

|

Shaft shedding |

|

|

down positive electronic cam shedding |

|

||

|

down positive electronic dobby shedding |

|

||

|

Electronic jacquard shedding |

|

||

|

Let-off |

|

AC servo continuous let-off |

Double warp beam |

|

|

Twin back beam |

|

|

|

|

positive or negative let-off |

|

|

|

Flange dia |

800mm |

1000mm |

|

|

Take-up |

Take-up method |

AC servo continuous take-up |

|

|

Batching method |

Entrails batching(max dia 600mm) |

|

|

|

out-engine batching(max dia 1000mm) |

|

||

|

temple |

upper |

|

|

|

Selvedge |

|

leno yarn by planetary gear |

|

|

Lubrication |

|

For main driving parts: oil-bath type, centralized filling oil(grease) |

|

|

Stop device |

Weft breakage |

Reflecting double feeler device |

|

|

Warp breakage |

Electric warp stop device |

|

|

|

others |

Selvedge, yarn end treatment, end-broken stop motion |

|

|

|

Stop display |

Screen display, multi-functional shutdown display lights |

|

|

|

Weft cutter |

|

Mechanical cutter |

|

|

Electric control system |

|

High-deficiency large screen VGA color image display touch human-computer interface |

|

|

|

|

|

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

Qingdao Saprk Yinchun Textile Machinery Co.,Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

-

11

- President

- Mr.Wang

- Address

- Wangtai Town,Jiaonan ,Qingdao City ,Shandong ,China

- Product Category

- Weaving Machinery

- Company introduction

-

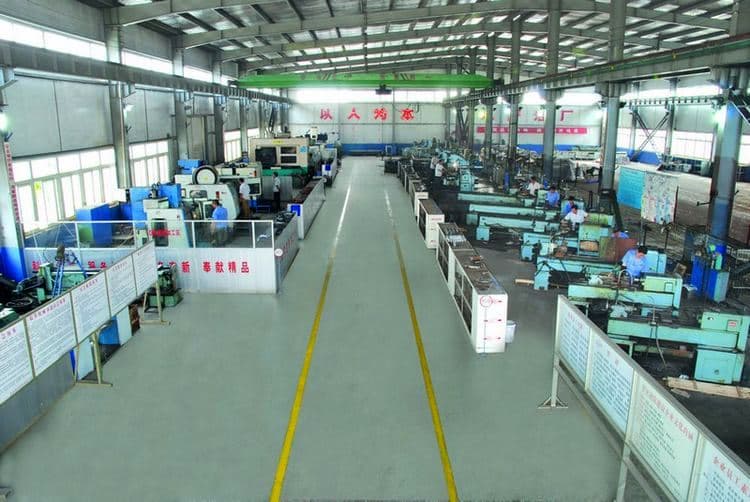

Qingdao spark yinchun Textile Machinery Co,.Ltd, a subsidiary of the group of Qingdao spark Textile Machine Co,.Ltd, is a member of China Textile Machinery Association. it has obtained the “GB/T19001-2008”quality system attestation,GB/T19022-2003 measurement management system attestation and honored as AAA-level enterprise by standardization Administration of the people’s republic of China. Besides, Qingdao spark yinchun Textile machinery Co,.Ltd is a major unit in drafting and developing industrious standards of jet looms. With decades of manufacture experience, professional technical workers and international leading CNC center, the company has been professional in manufacture of SJW series of water jet looms and YC series of air jet looms with national advanced level, stable performance and good reputation among buyers. Air jet looms lately invented have obtained many rewards at both provincial and national levels.

- Main Markets

-

South Korea

South Korea

- Main Product