Equal Thickness Grading Sieve

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Machinery & Parts

Chengdu Dahongli Machinery Co.,Ltd

- Country / Year Established

-

Hong Kong(China)

/

Hong Kong(China)

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | Equal Thickness Grading Sieve | Certification | - |

|---|---|---|---|

| Category | Machinery & Parts | Ingredients | - |

| Keyword | mining machine , equal thickness grading sieve | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

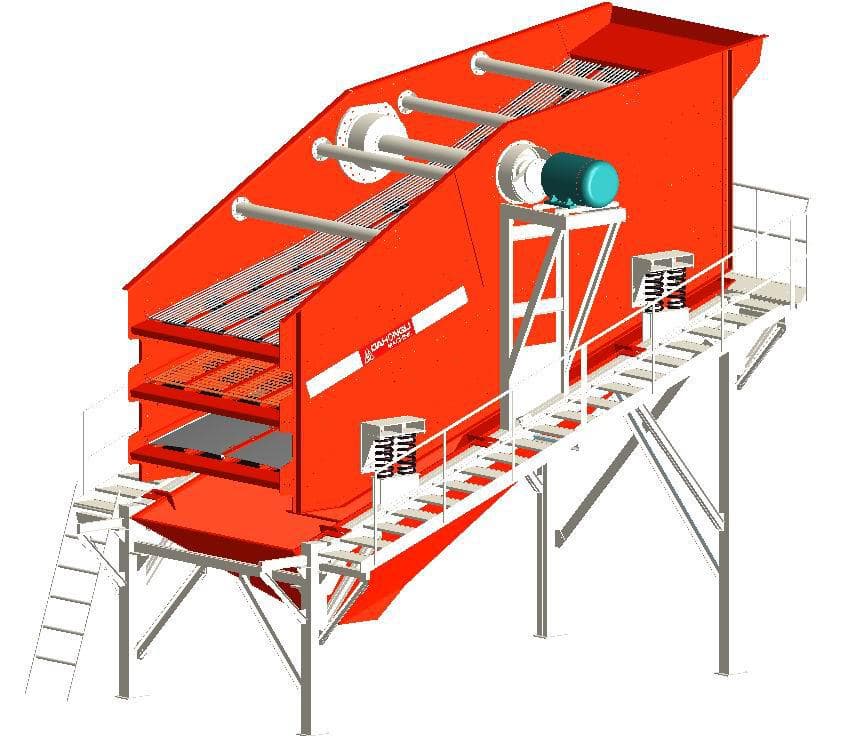

TK Series- Equal Thickness Grading Sieve

Product Introduction:

The product is ellipse motion Equal Thickness Grading Sieve.This product is characterized by reasonable structure,powerful excitation force,lower vibration noise,high efficiency in sieving and handling capability,easy to maintain and long service life.It’s widely used in quarries,mines,building materials,electric power,coal and chemical sectors.

Working principle:

The operation of linear motion Equal Thickness Grading Sieve is the motor pass through the elastic coupling drives the eccentric exciter,as the material layer on the sieving surface becomes loose,finer aggregates fall down through the layers and separate through the sieve hole,shaking out the material that stick in the sieve.At the same time finer aggregate moves downward and discharge through the sieve holes.The material moves forward to achieve discharge.

Product characteristics:

1.The sieving surface consists of multi-section angle.The material at the feed end flows quickly and at the discharge end flows slowly.The material at the feed end become to be layered rapidly,the rough aggregates going up and the fine aggregates going down.The screening efficiency is 1.5-2 times than ordinary sieve.The vibration sieve of this structure is especially suitable for handling the material that with high content of required material.

2.The machine is optimizing designed by finite element analysis,ensuring the strength of it and making the load as low as possible.At the same time, by abating the beam stress,it will connected with the high strength bolt which is good at self-locking and stability at the lateral panel.It can avoid the additional load caused by welding stress efficiently,and enhance the fatigue life of the machine.

3.The advanced great power seat type eccentric exciter with two units added tapered roller bearing makes the service life of the bearing longer.

4.The electric circuit is inverter brake connected.The vibrating sieve can turn off the machine safely and steadily,letting the sieve bed skip the sympathetic vibration area quickly and increases its service life.

5.The optimum designed spring unit reduces the noise efficiently.

6.The optimum designed cross girder structure greatly improves the availability of the sieve hole and makes the service life longer.

7.The screen mesh has three kinds of structure,module type and platen type,tensioning type.The module type use inlaid installation method and and is easy to change the screen mesh.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Mr Andy

- Address

- Chengdu Dahongli Machinery Co.,Ltd

- Product Category

- Home & Kitchen,Industrial Supplies,Mining Machinery

- No. of Total Employees

- 501-1000

- Company introduction

-

Chengdu Dahongli Machinery Co., Ltd (the “company”) is one of the most famous enterprises in China that specializes in the manufacture of sand and stone processing equipment and ore crushing & production line. With over twenty years of development, the company now is equipped with advanced production line and R & D center, as well as a professional team for research, design, manufacture, sales, installation, maintenance of products and related training. The company adopts advanced technologies from home and abroad, implements highly efficient development strategy, innovate technology as its core competitiveness, and follows a path of winning the market with quality and brand. It has developed over 80 products in eight categories, including the jaw type crusher series, cone type crusher series, vertical shaft impact crusher series, spiral type sand washing machine series, belt conveyor series, vibration type grading sieve series, reaction crusher series, and vibration feeding machine. Taking advantage of the west development program, Dahongli has accumulated vast expertise and experienced rapid growth, and has contributed to the Three Gorges Project, Chengdu-Chongqing High-speed Railway Project, Shuangliu International Airport Project, post-earthquake construction work in Sichuan, mine construction and urban-rural integration. With solid technical force, advanced production facility, excellent testing system, superior product performance, fast, quality, low-cost 24-hour after service, and a customer-oriented philosophy, the products of the company are sold around the country and in the international market, enjoying accolades from our customers. We will progress steadily along the way. Based on customer needs, we will gather up our force and make continued breakthrough, and translate the winning concept for quality products and service to practice, striving to bring about the perfect outcomes for our employees, our clients and the society. Dahongli Machine looks forward to joining hands with you to create a brilliant future!

- Main Markets

-

Australia

Australia

Belize

Belize

Bhutan

Bhutan

Brazil

Brazil

Cambodia

Cambodia

Chile

Chile

Cuba

Cuba

Egypt

Egypt

Falkland

Falkland

Ghana

Ghana

Guadeloupe

Guadeloupe

India

India

Indonesia

Indonesia

Iran

Iran

Ireland

Ireland

Libya

Libya

Malaysia

Malaysia

Mexico

Mexico

Myanmar

Myanmar

South Korea

South Korea

Tadjikstan

Tadjikstan

- Factory Information

-

Chengdu Dahongli Machinery Co., Ltd

- Main Product

Related Products

_2.jpg)

Cable and Wire harness tester (MHT-610 / 705)

_2.png)

Turbowin Turbo Compressor (WH Series)

KBC Bearing

NMB Bearing

MECHANICAL PACKING, GLAND PACKING, YARN ROPE PACKING