Friction Welding Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- U-JIN TECH CORP

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

U-JIN TECH CORP.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | Friction Welding Machine | Certification | - |

|---|---|---|---|

| Category |

Machinery & Parts

Other Metal & Metallurgy Machinery Welding Equipment |

Ingredients | - |

| Keyword | friction welding , friction welding machine , dissimilar metal weld | Unit Size | - |

| Brand name | U-JIN TECH CORP | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Friction Welding Machine

Advantage of Friction Welding

Improve Productivity

- Welding cycle time is short and high efficiency.

- Easily automated for mass production.

- Unskilled labourers can be used.

Improve Quality

- Constant quality is maintained and monitored.

- No air hole at welding points

Cost Savings

- No filler material, flux or shield gas

- Ability to weld dissimilar metal.

- No particular end preparation before welding

Green Environmental

- Low energy consumption

- No arcs, sparks, smoke or flames

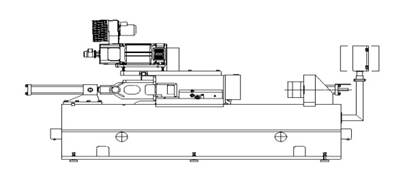

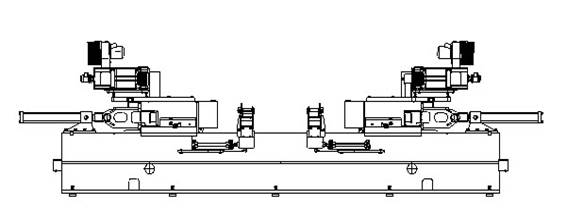

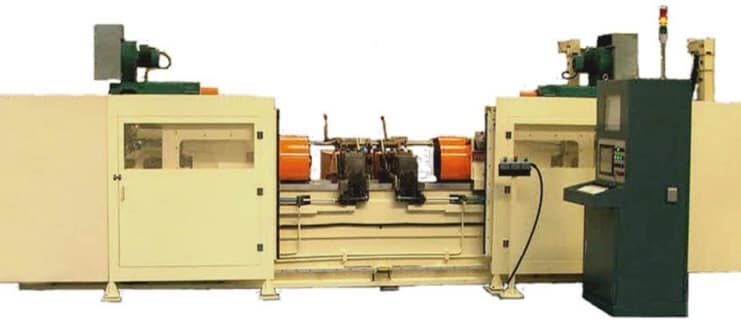

HYD. Friction Welding Machine

|

|

|

S (Single Spindle)

|

D (Double Spindle)

|

|

Technical Data

|

8DF/SF

|

15DF/SF

|

30DF/SF

|

60DF/SF

|

100DF/SF

|

125DF/SF

|

|

|

Nominal forge load

|

ton

|

8

|

15

|

30

|

60

|

100

|

125

|

|

Typical spindle power

|

KW

|

17.5

|

22

|

37.5

|

55

|

90

|

112

|

|

Max Spindle speed

|

rpm

|

3,000

|

2,500

|

2,000

|

1,300

|

1,000

|

1,000

|

|

Range weldable (mild steel)

|

mm

|

4`28

|

8~38

|

20~50

|

25~80

|

45~100

|

50~125

|

|

Max weld area (mild steel)

|

mm2

|

600

|

1,100

|

2,000

|

5,000

|

7,850

|

11,500

|

[Friction Welding Machine]

- Work: Propeller Shaft

- Material: S45C, STKM13

MODEL 15DF

|

Model

|

Spindle

Speed |

MAX. Forge

Force |

MAX.

Tube Diameter |

MAX. Weld

Area |

Spindle Drive

Motor |

|

15DF

|

2,300

|

15 Ton

|

Ø 100 mm

|

1,100mm2

|

60KW

|

MODEL 60DF

|

Model

|

Spindle

Speed |

MAX. Forge

Force |

MAX.

Tube Diameter |

MAX. Weld

Area |

Spindle Drive

Motor |

|

60DF

|

1,500

|

60 Ton

|

Ø 145 mm

|

5,000mm2

|

83KW

|

MODEL 5SF

- Work: Inflator (Air Bag)

- Material: SPFC

|

Model

|

Spindle

Speed |

MAX. Forge

Force |

MAX.

Tube Diameter |

MAX. Weld

Area |

Spindle Drive

Motor |

|

5 SF

|

3,500 rpm

|

5 Ton

|

Ø 20 mm

|

350 mm2

|

17.5 KW

|

MODEL 8SF

- Work: Cam Shaft

- Material: S45C, STKM

|

Model

|

Spindle

Speed |

MAX. Forge

Force |

MAX.

Tube Diameter |

MAX. Weld

Area |

Spindle Drive

Motor |

|

8 SF

|

1,700 rpm

|

8 Ton

|

Ø 28 mm

|

600 mm2

|

17.5 KW

|

MODEL 8SF

- Work: Intermediate Shaft

- Material: S45C, STKM

|

Model

|

Spindle

Speed |

MAX. Forge

Force |

MAX.

Tube Diameter |

MAX. Weld

Area |

Spindle Drive

Motor |

|

10 SF

|

2,000 rpm

|

10 Ton

|

Ø 32 mm

|

800 mm2

|

30 KW

|

MODEL 100SF

- Work: Track Roller

- Material: S45C

|

Model

|

Spindle

Speed |

MAX. Forge

Force |

MAX.

Tube Diameter |

MAX. Weld

Area |

Spindle Drive

Motor |

|

100 SF

|

1,000 rpm

|

10`0 Ton

|

Ø 180 mm

|

7,850 mm2

|

108 KW

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Sung Yoon, Kim

- Address

- 735-3, Yangno-ri, Bibong-myeon, Hwaseong-si, Gyeonggi-do, Korea

- Product Category

- Machinery & Parts

- No. of Total Employees

- 1-50

- Company introduction

-

U-Jin Tech cooperation commit to contribute for development and supply the Friction welding machine through advanced technology and long term experience as Friction welding machine maker and processing welding business. We shall make efforts constantly to improve of valuable customer’s business as Friction welding machine specialist maker. We shall create the advanced company of Friction welding machine in the world and fulfill for split of sharing and coexistence.

- Main Markets

-

China

China

South Korea

South Korea

- Main Product

Related Products

Date Pin (Date Core)

_2.jpg)

Micro Probe System (MPS-PTH)

UIM2901-5A MACH3 break out board for CNC

Portable line boring machine, Elsa Supercombinata EASY Compact

AIS3000 HD