Regenerative Desiccant Dryer

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery & Industry Equipment

Bauman Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | Regenerative Desiccant Dryer | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

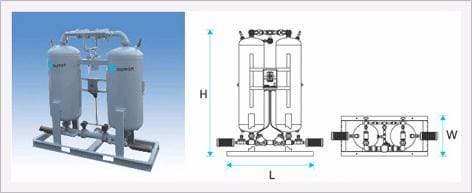

Heatless - AML Series

Model & Specifications of Heatless

|

Modelï¼¼Spec. |

Flow | Dimension | In / Out | Weight | |

| Nm3/min | LxWxH (mm) | Inch | Desiccant (KG) | Total weight (KG) | |

| AML10 | 1.3 |

840 x 310 x 1,520 |

3/4" (20A) |

25 | 136 |

| AML15 | 1.95 | 840x 310 x 2,070 | 3/4" (20A) | 38 | 159 |

| AML20 | 2.6 | 1,150 x 450 x 1,755 | 1 "(25A) | 50 | 250 |

| AML30 | 3.9 | 1,150 x 450 x 1,755 | 1 " (25A) | 57 | 260 |

| AML40 | 5.2 | 1,150 x 490 x 1,790 | 1 1/2"(40A) | 87 | 306 |

| AML50 | 6.5 | 1,270 x 555 x 1,790 | 1 1/2"(40A) | 124 | 405 |

| AML75 | 9.75 | 1,270 x 585 x 1,880 | 1 1/2"(40A) | 174 | 473 |

| AML100 | 13 | 1,400 x 688 x 2,130 | 2 " (50A) | 248 | 653 |

| AML150 | 19.5 | 2,100 x 890 x 2,400 | 3" FLG (80A) | 397 | 900 |

| AML200 | 26 | 2,100 x 890 x 2,430 | 3" FLG (80A) | 496 | 1,125 |

| AML300 | 39 | 2,590 x 1,065 x 2,800 | 3" FLG (80A) | 694 | 1,575 |

| AML400 | 52 | 2,590 x 1,065 x 2,830 | 4" FLG (100A) | 862 | 1,980 |

| AML500 | 65 | 2,590 x 1,205 x 2,830 | 4" FLG (100A) | 1,123 | 2,475 |

| AML600 | 78 | 2,590 x 1,205 x 2,900 | 4" FLG (100A) | 1,361 | 2,970 |

- Based on average Inlet temperature 38â and Pressure 7ã/ã .

- Basic dew point is -40â, models for -70â as well as explosion-proof construction is possible

- Power specifications are 220V/1PH/50~60Hz

- Products of over AML 100 are designed for Korea Occupational Safety and Health Agency inspections

- Custom products of greater capacity than listed are possible

- These specifications may be modified to improve quality.

Modified constant

|

|

||||||||||||||||||||||||||

| Inlet temperature | Inlet pressure |

Internal Heater - AMI Series

Feature

- Internal Heater dryers contain an internal heater element that in reases recycled heat efficiency, reducing air consumption and increasing costeffectiveness

- Uses an auxiliary heater similar to that used by external heater units, reducing power consumption

- An oil-less pneumatic valve enxures precise operation, with speed-adjusting cylinders inside the valves to reduce shock and prevent malfunctions

- Cycles can be set to 8hr cycles as well as 12hr and 16hr cycles, with further customization possible

- Drop in line pressure shuts down the purged air, ensuring a stable outlet pressure and operational safety

Model & Specifications of Internal Heater

|

Modelï¼¼Spec. |

Flow | Dimension | In / Out | Heater | Weight | |

| Nm3/min | LxWxH (mm) | Inch | Kw | Desiccant (KG) | Total weight (KG) | |

| AMI50 | 6.5 |

1,000 x 1,000 x 2,450 |

1 1/2"(40A) |

3.6 | 210 | 850 |

| AMI75 | 9.75 | 1,150 x 1,150 x 2,600 | 2 " (50A) | 5.4 | 260 | 1,000 |

| AMI100 | 13 | 1,150 x 1,150 x 2,600 | 2 " (50A) | 7.0 | 400 | 1,100 |

| AMI150 | 19.5 | 1,700 x 1,600 x 2,700 | 2 1/2"(65A) | 10.2 | 520 | 1,650 |

| AMI200 | 26 | 1,800 x 1,600 x 2,700 | 3" FLG (80A) | 12.0 | 700 | 2,000 |

| AMI300 | 39 | 2,200 x 1,600 x 2,800 | 3" FLG (80A) | 15.0 | 920 | 2,900 |

| AMI400 | 52 | 2,400 x 1,600 x 2,960 | 4" FLG (100A) | 27.0 | 1,050 | 3,300 |

| AMI500 | 65 | 2,500 x 1,800 x 3,000 | 4" FLG (100A) | 30.0 | 1,470 | 4,500 |

| AMI600 | 78 | 2,800 x 2,000 x 3,000 | 6" FLG (150A) | 42.0 | 2,100 | 5,500 |

- Based on average Inlet temperature 38â and Pressure 7ã/ã .

- Custom products of greater capacity than listed are possible

- These specifications may be modified to improve quality.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Kim Yun-chul

- Address

- 553-6 Midong-ri, Iwon-myeon, Okcheon-gun, Chungchongbuk-do, 373-861, Korea

- Product Category

- Hand Tools

- No. of Total Employees

- 51-100

- Company introduction

-

Founded in 1999, Bauman Co., Ltd. has focused on developing compressed air purification systems, and became the first Korean company to successfully localize the deliquescent air dryer through a partnership with Vanair Inc., U.S. specialist in the field.

Bauman continues to develop new and innovative air dryer systems by constantly addressing and improving the limitations of traditional air dryers.

The deliquescent air dryer can be installed in locations that can not accommodate traditional air dryers.

The dryers do not require a power source, enabling energy cost savings and contributing to the operator's competitive capabilities.

In addition, Bauman is preparing the foundations for overseas exports and expansion through the development of eco-friendly desiccants.

- Main Product