Recipient Block Mold Kit

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

Unitma Co., Ltd.

- Verified Certificate

-

11

| Product name | Recipient Block Mold Kit | Certification | - |

|---|---|---|---|

| Category | Other Examination & Testing Instrumnet | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Recipient Block Mold Kit

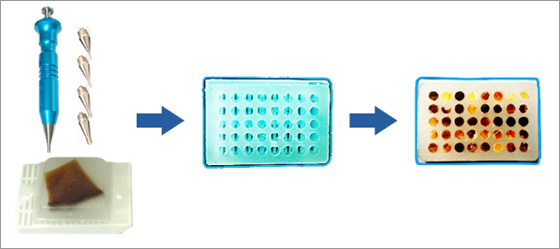

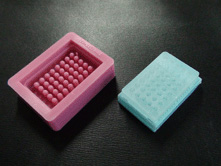

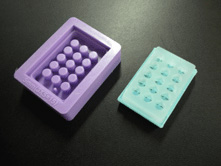

Recipient block mold kit is an alternative solution for the users to prepare the recipient block by themselves.

The recipient block can be used to prosecute TMA works with the manual tissue microarrayer called Quick Ray.

Furthermore, the researchers can prepare the hundreds of recipient blocks if the mold kits made from the silicon rubber, are stored and handled with care.

* Tissue Microarray with the 3mm core-sized block and tip (among 1, 1.5, 2, 3 and 5 mm)

* Tissue Microarray with the 3mm core-sized block and tip (among 1, 1.5, 2, 3 and 5 mm)

|

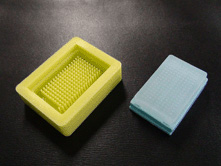

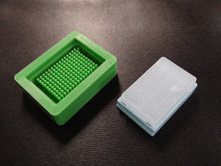

Core Size: 1mm x 170 holes (10 x 17)

|

|

1mm Quick-Ray manual tissue microarrayer

|

|

Core Size: 1.5mm x 150 holes (10 x 15)

|

|

1.5mm Quick-Ray manual tissue microarrayer

|

|

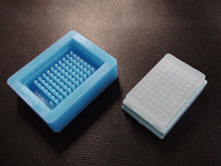

Core Size: 2mm x 70 holes (7 x 10)

|

|

2mm Quick-Ray manual tissue microarrayer

|

|

Core Size: 3mm x 40 holes (5 x 8)

|

|

3mm Quick-Ray manual tissue microarrayer

|

|

Core Size: 5mm x 15 holes (3 x 5)

|

|

5mm Quick-Ray manual tissue microarrayer

|

Specification

|

Product name

|

Premade Recipient Block

|

|

|

Model Number

|

Core size

|

Number of cores

|

|

UM01 - 1

|

1mm

|

170 (10 x 17)holes

|

|

UM01 - 1.5

|

1.5mm

|

150 (10 x 15) holes

|

|

UM01 - 2

|

2mm

|

70 (7 x 10) holes

|

|

UM01 - 3

|

3mm

|

40 (5 x 8) holes

|

|

UM01 - 5

|

5mm

|

15 (3 x 5) holes

|

|

Outside Dimension

|

24 x 30 x 5.5 mm

|

|

|

Inside Dimension

|

White, odorless

|

|

|

Weight

|

Solid

|

|

|

Storage temperature

|

Room temperature

|

|

|

Material

|

5°C ~ 35°C

|

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Lee Youngdo

- Address

- 3F,Chungmyeong B/D,224-8, Jamsil-dong, Songpa-gu, Seoul, 138-220, Korea

- Product Category

- Other Clinical Analytical Instrument

- No. of Total Employees

- 1-50

- Company introduction

-

UNITMA Co., Ltd. is a leading provider of products and services for excellent diabetic therapy devices, and for medical devices that improve productivity and efficiency in clinical, analytical and research laboratories in the field of histopathology. Since its establishment in 2006, UNITMA Co. Ltd. has been growing rapidly based on the innovative platform technologies and prospective business philosophy.

UNITMA Co. Ltd. has been receiving good reputations for its products and services from the existing customers including world's prestigious university hospitals and laboratories. UNITMA Co., Ltd. will strive to commit itself to provide improved products and services aiming on helping better life of patients and advanced research and development environment of medical research professionals.

UNITMA carbon heating film is based on a continous resistive sheet providing heat evenly over the black surface areas.

UNITMA carbon film consisits of a specially formulated semi-conductive medium,coated onto polyester film.Power is fed to this resistive coating by way of copper eletrodesthat are fixed to the longitudinal edges of the heating areas.

This structure is insulated by a lamination of polyester based films that totally cover the element and is wider than the conductive heating area,forming strong clear edges that are designed to accept subsequent fixing to sub floor surfaces.

Low temoerature carbon floor heating films produces a gentle heat that evenly warms the entire room.Once the surfaces have been warmed,the heat is reflected resulting in comfortable ,natural warmth with minimum floor to ceiling termperature variation.

The conventional manufacturing way of carbon heating involves the fragmented processes of silk screening printing of the paste on to a PET laminex sheet. This sheeting is then subjected to high temperature in baking chamber. UNITMA film heater product is highly stable. It is also more resistant to heat and less susceptible to

- Main Product

Related Products

Suction Catheter

PowerChek SARS-CoV-2 S-gene Mutation Detection Kit Ver.1.0

Thoracic Catheter

Nurugo CPR manikin

CRYSTE Multi purpose Centrifuge VARISPIN 4

South Korea

South Korea