Samwon Tuksu Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | Packer | Certification | - |

|---|---|---|---|

| Category | Pumps | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Packer

Overview

Patented construction method preventing water-tight layer form destruction mainly because of cracks or its swelling/coming off as expansion matters such as moisture generated form layers under the water-tight layer, which is exposed and directly affected by temperature are emitted.

A Method of Construction for Injection

|

1. Crack and leakage condition inspection Check the process procedure after finding the thickness, width and depth of crack and leakage condition of the structure |

|

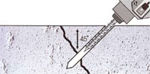

2. Drilling Operation Drill directly into crack section if the thickness of concrete is thinner than 10cm. For the thickness of 10cm ~ 50cm, drill it with 45 degree angle by keeping a distance of 1/5 of concrete thickness. Make sure it penetrates the crack section. If the thickness is over than 50cm, keep the distance of 20cm ~ 30cm and drill it with 45 degree angle until it penetrates crack section. And keep drilling by maintaining the fixed interval. (5 holes per 1 meter. Drill it in zigzags) |

|

3. Packer Installation Clean the inside of drilled holes with compressor. Make sure that rubber sleeve of packer and cutting line of tightening nut should be put into the inside of concrete surface when installing. Tighten the packer completely by using the T-box. (Packer might be damaged if you tighten it too strongly) |

|

4. Injection Operation Inject the urethane water stopping material by using the high pressure device or grease gun. Maintain the initial injection pressure as around 40kg/cm and increase the pressure by each 10kg/cm gradually until the water stopping material flows out from crack section. Water will come out from the crack section first and then water stopping foaming agent and then water stopping liquid at last. If the water stopping material that is not foamed comes from the crack section, then move to next packer for injection. |

|

5. Packer Removing Operation Remove and break the packer by using vise pliers or hammer as a tool. If there is still a wet section, then inject the water stopping material again. |

|

6. Finishing Operation Remove the water stopping material that is remained on the crack section. Spreading with the elastic sealing material. |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Dongil Kim

- Address

- 440-4 Sangdae-dong, Yuseong-gu, Daejeon, Korea

- Product Category

- Pumps

- No. of Total Employees

- 1-50

- Company introduction

-

Samwon Company has been devoted to water leakage, repair and reinforcement of concrete constructions since 1990. We have undertaken our constructions under the principle that we must be the best at repairing all defects from cleaves, water leakages of constructions 40m underwater to buildings, engineering works, installing of equipment. We have also been on observation tours abroad to study repair and reinforcement of constructions all over the world.

We will repay for your precious encouragement through experienced constructions and careful selection of materials.We are planning overseas expansion supported by our accumulated experience and know-how. We are aware that all of our achievements have been possible only through our customers' encouragement, which we will repay for by securing reliability in all our constructions.

- Main Markets

-

Malaysia

Malaysia

Taiwan

Taiwan

- Main Product

Related Products

AIRLESS PUMP - YL 451

GOLDEN AUTO GREASE PUMP - INTERLUBE

Clean pump / submersible pump S50

HYDRAULIC PRODUCTS

Airless Pump (Ratio 63:1 Airless Pump)