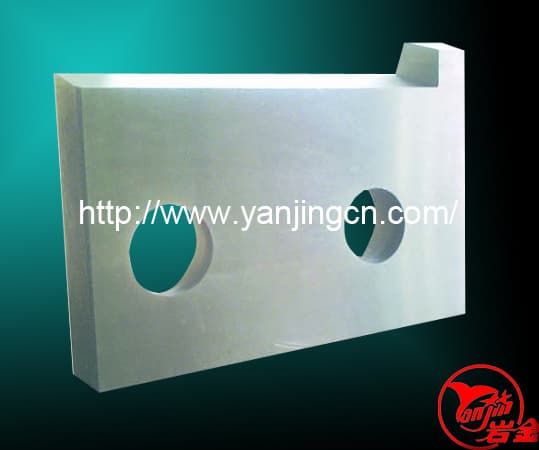

Flying shearing blades for cutting deformed steel bar

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- Yanjing

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- shearing blade, deformed bar cutting blade, deformed steel bar shearing blade, flying shearing blade

- Category

- Other Metal & Metallurgy Machinery

Jinhai Metallurgical Machinery Building Co.,Ltd Maanshan

- Verified Certificate

-

12

| Product name | Flying shearing blades for cutting deformed steel bar | Certification | - |

|---|---|---|---|

| Category | Other Metal & Metallurgy Machinery | Ingredients | - |

| Keyword | shearing blade , deformed bar cutting blade , deformed steel bar shearing blade , flying shearing blade | Unit Size | - |

| Brand name | Yanjing | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | 8455900000 |

Product Information

1.Twenty-four year professional experience

2.We are END MANUFACTURER

3.Competitive price

4.OEM and ODM

5.We make steel by ourselves,so the materials are various .

6.All products are from forged steel billet,not from steel plate.Forging steel make the inside microstructure become much closer and the metal grain size becomes much smaller to ensure a long worklife.

7.Specializes in shearing machine blades,slitting machine knives and other cutting tools for industrial machines .

8.Blade:maximum length of 5800mm and maximum diameter of 1500mm

9.Materials:D2,SKD11,5CrW2Si, 6CrW2Si, Cr12MoV, 9CrSi, H13 and self-developed H13k, HMB and HMK high various alloy steel

10.High intensity, high hardness, high toughness, and high hardenability, etc.

11.Widely used in industries of steel, rubber, papermaking, and so on.

12.Passed the ISO9001 quality certification in 2001,Each technical index reaches the international standard.

Operatinal Progress:

Steel-making— Blanking— Forging Steel— Rough Progressing— Heat Treatment— Finishing— Testing

Steel-making by medium frequency furnaces

Steel-making begins from the start of this century in Jinhai Company. So the company can meet special requirements for materials. In order to guarantee the quality, Jinhai company imported spectrometer from Germany and is equipped with various tester, such as tensile tester, impact testing machine, metallography analyzer and so on.

Electro slag remelting

The largest ingot can reach 3 tons in Jinhai company. The ingot obtained by this remelting/refining process is very homogeneous and free of internal defects. The segregation of the ingot(called macro-segregations) are substantially eliminated and the segregations of crystals(called micro-segregations)are significantly reduced. The ESR remelted material improve following mechanical characteristics:

. Improved toughness due to increased homogeneity and isotropy

. Improved creep resistance properties

. Best fatigue strength and tenacity properties as well as outstanding tensile strength

. Improved purity

Forging steel

Forging process can trance to 1990s in Jinhai company. The largest electro-hydraulic hammer is 4.5 ton. And more than 6 skilled technicians work here. After forging the inside microstructure becomes much closer and the metal grain size becomes much smaller. It can elevate the characteristics and quality of the knife ensuring a longer life of the knife.

Rough processing

No less than 40 sets of processing equipment in the rough processing workshop of Jinhai company, including lathe, milling machine, planer, drill machine etc. Skilled workers are employed in its rough processing workshop.

Heat treatment

Jinhai company has independent workshop for heat treatment. Couples of skilled technicians work here. Actually, all blades(thickness less than100MM)can be fully hardened. Thus, the blades can be used after repairing until the size reached the minimum design dimension.

Finishing processing

Jinhai company has more than 35 sets of processing equipment including internal grinder, external grinder, surface grinder, CNC grinder, electric spark CNC wire-cut etc. The company can produce the shearing blades with 5800mm in length and slitting knives with 1500mm in outside diameter.

Testing

Various testers are put to use for testing its products in Jinhai company. They are including tensile tester impact testing machine, metallography analyzer, harmless flaw detector, magnetic powder inspection, hardness tester, caliper rule, microcalliper, etc. Testing is carried out after each step. And every products has a unique tracking number. Thus it is easy to trace back anytime.

Jinhai company has one independent R&D department which is fully equipped with experimental and testing facilities. Until now, we have developed some high alloy steel ,like HMB,HMK etc.They are new materials independently developed by our company and excellent in high intensity, high hardness,high wear resistance ,high toughness ,high hot hardness and so on. They can be used in both cold and hot shearing and have been rewarded the national invention patens. The life of blades and knives made of HMB and HMK is 2-3 times longer.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Jinhai Cao

- Address

- Pingqiao Village, Bowang Town, Dangtu County, Ma'anshan, Anhui, China (Mainland)

- Product Category

- Industrial Supplies,Machinery & Parts

- No. of Total Employees

- 101-500

- Company introduction

-

Ma'anshan Jinhai Metallurgy Machinery Manufacturing Co., Ltd., established in 1988,is a specialized manufacturer meeting the customers requirements in metal smelting, forging, rough machining, finish machining, heat treatment, testing, analysis and research, development and selling,etc. Located in China First Cutting Tool Town--Bowang, currently, it covers an area of 55,000 square meters and has more than 160 employees and no less than 140 sets of processing equipments. It specializes in manufacturing of kinds of cutting tools, including various types of cutting blades, rolls, wear sliders and so on. It manufactures blades with maximum length of 5,500mm and maximum diameter of 1,500mm, widely used in industries of steel, rubber, paper making, and so on. The materials of the products consist a variety of traditional 5CrW2Si, 6CrW2Si, Cr12MoV, 9CrSi, H13 and independently developed H13K, HMB and MHK high alloy steel, which receive China Patent for Invention. The products has the features such as high intensity, high hardness, high toughness, and high hardenability. When the products are used to cut plates, wires and silicon steels, the incision is smooth and free of burr and has a long working life. The company has passed the ISO9001 quality certification in 2001 and has become one regular supplier to Baosteel, Masteel, Nanjing Steel, Panzhihua Steel, Tianjin Steel, and Jinan Steel, and so on. With its rich manufacturing experience, high-quality products, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing cutting tools series.We sincerely hope to establish business relation with you and pursue mutual benefit.

- Main Markets

-

Belarus

Belarus

Brazil

Brazil

Germany

Germany

Malaysia

Malaysia

Romania

Romania

Russia

Russia

South Korea

South Korea

U.A.E.

U.A.E.

Viet Nam

Viet Nam

- Main Product

Related Products

10t Air drop hammer, mod. M2150, Kramatorsk

PRINTEX

UIM2901-5A MACH3 break out board for CNC

Custom-Made Hydraulic Cylinder (( Made in Korea))

Automatic precision metal cutting machine

China

China