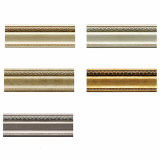

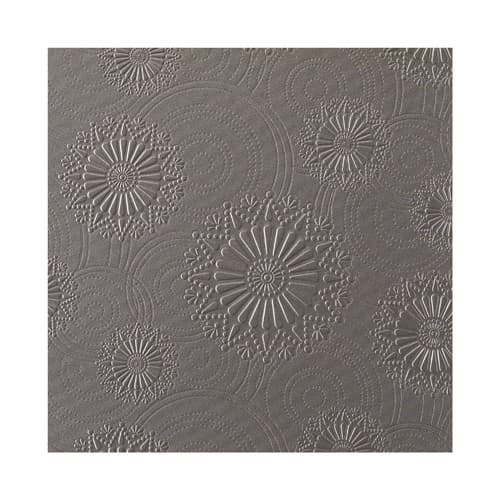

Woodpulp MDF Decorative Panel/Moulding

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- WoodenPulp Panel & Moulding

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- 3d panel, interior/construction/furniture material, mdf decorative panel, woodpulp mdf decorative panel

- Category

- Mouldings

EcoOne Holdings Limited.

- Verified Certificate

-

11

| Product name | Woodpulp MDF Decorative Panel/Moulding | Certification | - |

|---|---|---|---|

| Category | Mouldings | Ingredients | - |

| Keyword | 3d panel , interior/construction/furniture material , mdf decorative panel , woodpulp mdf decorative panel | Unit Size | - |

| Brand name | WoodenPulp Panel & Moulding | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

Woodenpulp MDF Decorative Panel& Moulding

│ DESCRIPTION │

What is Wooden Pulp product?

Wooden pulp is in kneaded style, mixed with wooden pulp, vegetable oil, glue and other additives. After pattern is imprinted by using mold and it is processed by drying procedure, it can be produced as panel or moulding product which have same appearance as lumber with medium density hardness. This product is half-finished good in timber color and becomes complete product, such as wooden pulp panel, wooden pulp moulding which has showy color and pattern, through painting work by paint product, or works using sheet product.

The use of Wooden Pulp

The wooden pulp is originally and widely used for precise and detailed shape, classical design, interior sculpture and the area which needs hand processing procedure. However, in Korea, it is used and popularized for furniture use and establishes itself gradually as interior materials for building and interior design, and it is currently used for the purpose of decoration or reform in various place, such as all sorts of furniture, console, door, sink, finishing of wall surface, pillar and lamplight box.

The characteristic of wooden pulp

It has same pattern and fancy color as woodcraft product and also has three-dimensional effect surpassing two-dimensional limit of current panel. You can easily get quality which you want with less paint than CNC controlled product when painting work.

Limitation of wooden pulp

There is limitation in using wooden pulp as independent structural material or finishing material since it can be bent like MDF which has medium density hardness.

Point that you have to pay attention when handling

1. Do not store it near naked flames or in humid place as wooden pulp has, in material characteristic, weak durability against naked flames and water.

2. Store it in cool and shady place where air is well ventilated.

- When exposed in strong sunlight, the product becomes strong(hard), which makes it vend, and painting product can be cracked during transportation.

- It can be damaged(decolorization, going moldy) when storing in humid place.

3. As it is in the form of half-finished good processed by product with medium density hardness, it can be damaged when loaded by mixture with heavy products.

- It can be scratched, pressed, broken.

The standard for loading (above 18T, excluding MDF) : Store less than 100 sheets of board when accumulating board - When storing 18T board pallet : Please store it in single layer, storing in double layer can cause distorting pattern and vending.

4. When cutting by using board cutter(running saw), total quantity should not exceed height of 30T

- Processed product which exceeds 15T should by cut by one sheet each, Cutting more 2 sheets each makes edge side not smooth.(It differs form each manufacturer)

5. When carrying moulding/board board, please carry it, being held by more than 2 persons.(Do not hold in the middle)

- When carrying moulding product, do not raise it on the shoulder, which many cause crack on the product.

6. When painting with moulding of half-finished product, please use suitable quantity of paint.

- Excessive painting of paint/Thinner at the time of first painting may cause detachment of product(Use little quantity of paint without fail)

7. Direct heat drying may also cause product defect(detachment), therefore please maintain suitable distance when drying.

The "Woodenpulp" is in kneaded style, mixed with wood flour/ vegetable oil/glue and other additives. After pattern is imprinted by using MOLD and it is processed by drying procedure. It can be produced as panel or moulding product which have same appearance as lumber with "MEDIUM DENSITY HARDNESS". This product is half-finished good in timber color and becomes complete product, such as; Woodenpulp Panel, Woodenpulp Moulding which has showy color and pattern, through painting work by Paint Product or PVC/PET Film Product.

│ FUNCTION │

│ FEATURES │

│ SPECIFICATION │

- E1 Grade MDF Board

- Wood flours Material for Emboss process (Imported from Italy).

- Using Good quality of PVC/ PET Films on the surface.

- 1,220mm(width) x 2,440mm(length) x 1 to 18mm(thickness)

- Sizes are depends on Model Number(Please refer to our E-Catalog& website).

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Myeong seon, Jeon

- Address

- Industy-Academic Cooperation Foundation #208, Korea Polytechnics University Ⅱ,56, Munemi-ro 448 beon-gil, Gusan-dong, Bupyeong-gu, Incheon, Korea

- Product Category

- Marble & Limestone,Mouldings,Plastic Sheets

- Year Established

- 2012

- No. of Total Employees

- 1-50

- Company introduction

-

EcoOne Holdings Limited is a manufacturer that specializes in production and distribution of home interior products such as PET-G decorative sheet/film, decoration moulding/panel, Quick stone Floor, etc.

We have established a company affiliated laboratory in consideration of the environment, to create a better living environment and to facilitate advanced technology development.

We will conduct ceaseless research and development to achieve technology development for comfortable and eco-friendly future environmental design. We will also exert out utmost effort to develop environmentally friendly raw material, as well as to improve residential environment.

- Main Markets

-

China

China

India

India

Poland

Poland

Turkey

Turkey

U.S.A

U.S.A

- Factory Information

-

EcoOne Holdings Limited

- Main Product

Related Products

Aluminum Formwork System

WT4 Stair Tread

Plastic frame moulding

HOT STAMPING FOIL FOR MDF, SUPER WHITE MATT

Deco Moulding

South Korea

South Korea