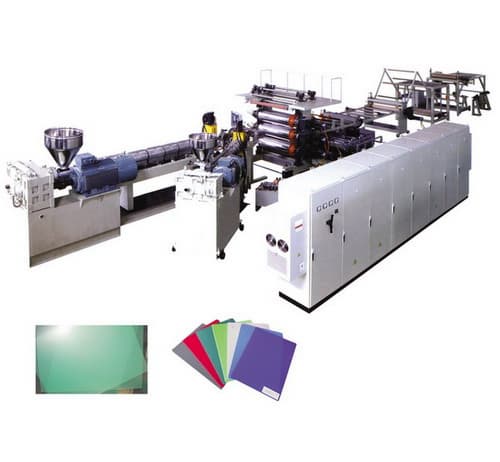

PE-PP-PS-PVC-ABS-PMMA -PC Board Production Line

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- Keshengda Machinery

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Machinery & Parts

QingDao Keshengda plastic machinery Co., Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | PE-PP-PS-PVC-ABS-PMMA -PC Board Production Line | Certification | - |

|---|---|---|---|

| Category | Machinery & Parts | Ingredients | - |

| Keyword | pe/pp board production line , plastic board extruder | Unit Size | - |

| Brand name | Keshengda Machinery | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

PE-PP-PS-PVC-ABS-PMMA-PC Board Production Line/Plastic Board Extrusion line/Plastic Board Extruder:

The production line can continuously produce PP, PE, ABS, PMMA, PC, PS, PVC single-and multi-sheet products. The sheet has width of 2000mm or below and thickness of 0.15-3mm. Extruder: According to different materials, the single screw extruder is differentiated by exhaust type and non-exhaust type. The extruder screw has special mixing function and precise temperature control system to ensure a high plasticizing plastic, high yield and stable extrusion .

Temperature control of ± 1 ℃ can accurately control the plasticizing process and sheet thickness, flat plastic. Changer and die: hydraulic quick changer facilities ensures no material leakage, which makes net changing quick and efficient; according to different materials, moulds choose different structure, the die head of hanger shape adops double throttling for numbers of sheet pages, which is easy for adjusting flow distribution to be equal, and adjusting the thickness of extruded board sheets to be more exclusive.

Main technical parameter

|

Model |

SJ90 |

SJ-120 |

SJ-150 |

|

Material |

PE PP PS PVC ABS PMMA PC |

PE PP PS PVC ABS-PMMA PC |

PE PP PS PVC ABS PMMA PC |

|

Product width /mm |

1220-1500 |

1220-2000 |

1200-2000 |

|

Product Thickness/ mm |

0.5-8 |

1.5-10 |

1.5-10 |

|

Screw L/D ratio |

32-34 |

32-36 |

30-36 |

|

Max.Production capacity/ kg/h |

260 |

400 |

500 |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- lunar sun

- Address

- NO.82,Yangzhou West Road,Jiaozhou,Qingdao

- Product Category

- Plastic Product Making Machinery,Plastic Raw Material Machinery

- No. of Total Employees

- 51-100

- Company introduction

-

QingDao Keshengda plastic machinery Co., Ltd is located in Jiaozhou city, Shandong province, which is professional manufacturer and exporter of plastic machinery,main products include PVC/PE Wood Profile Extrusion Line, PE/PVC Pipe Production Line, PP/PE/PVC Board Extrusion Line, PP/PC hollow sheet Production Line, WPC Foam Board Production Line, PP/PET strap band production line, etc The company always obeys the principle of “credit is the basis, quality is the life, innovation is the pursue , service is the main ” , keeps the quality promise for customers, focuses on introducing and cultivating talent, cooperates with many science and research institutes, has strong technology power and perfect testing means, integrates advanced technology advantages and rigid equipments and has introduced many technologists with working experience in research and development and fabrication of plastics processing whole equipments, and understanding and experience accumulation in plastics process and plastics machinery design matching; all of these have ensured high quality and excellent performance of our fabrication of plastics machinery equipments.

- Main Markets

-

Bangladesh

Bangladesh

India

India

Philippines

Philippines

South Korea

South Korea

Sri Lanka

Sri Lanka

Sudan

Sudan

Sweden

Sweden

Togo

Togo

Tunisia

Tunisia

Uruguay

Uruguay

Uzbekistan

Uzbekistan

- Factory Information

-

QingDao Keshengda plastic machinery Co., Ltd

- Main Product

Related Products

Torrington Bearing

KBC Bearing

AIS3000 HD

UIM2901-5A MACH3 break out board for CNC

NEMA17 42mm stepper motor with driver or controller