Epoxy Mold Casting Plant for Cast Resin Transformer

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- DKM-VCP

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- transformer, cast resin, dry type transformer, epoxy mold

ALU KOREA

- Verified Certificate

-

16

| Product name | Epoxy Mold Casting Plant for Cast Resin Transformer | Certification | - |

|---|---|---|---|

| Category |

Machinery & Parts

Passive Components Other Machinery & Industry Equipment Molds Cast & Forged |

Ingredients | - |

| Keyword | transformer , cast resin , dry type transformer , epoxy mold | Unit Size | - |

| Brand name | DKM-VCP | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | 845430 |

Product Information

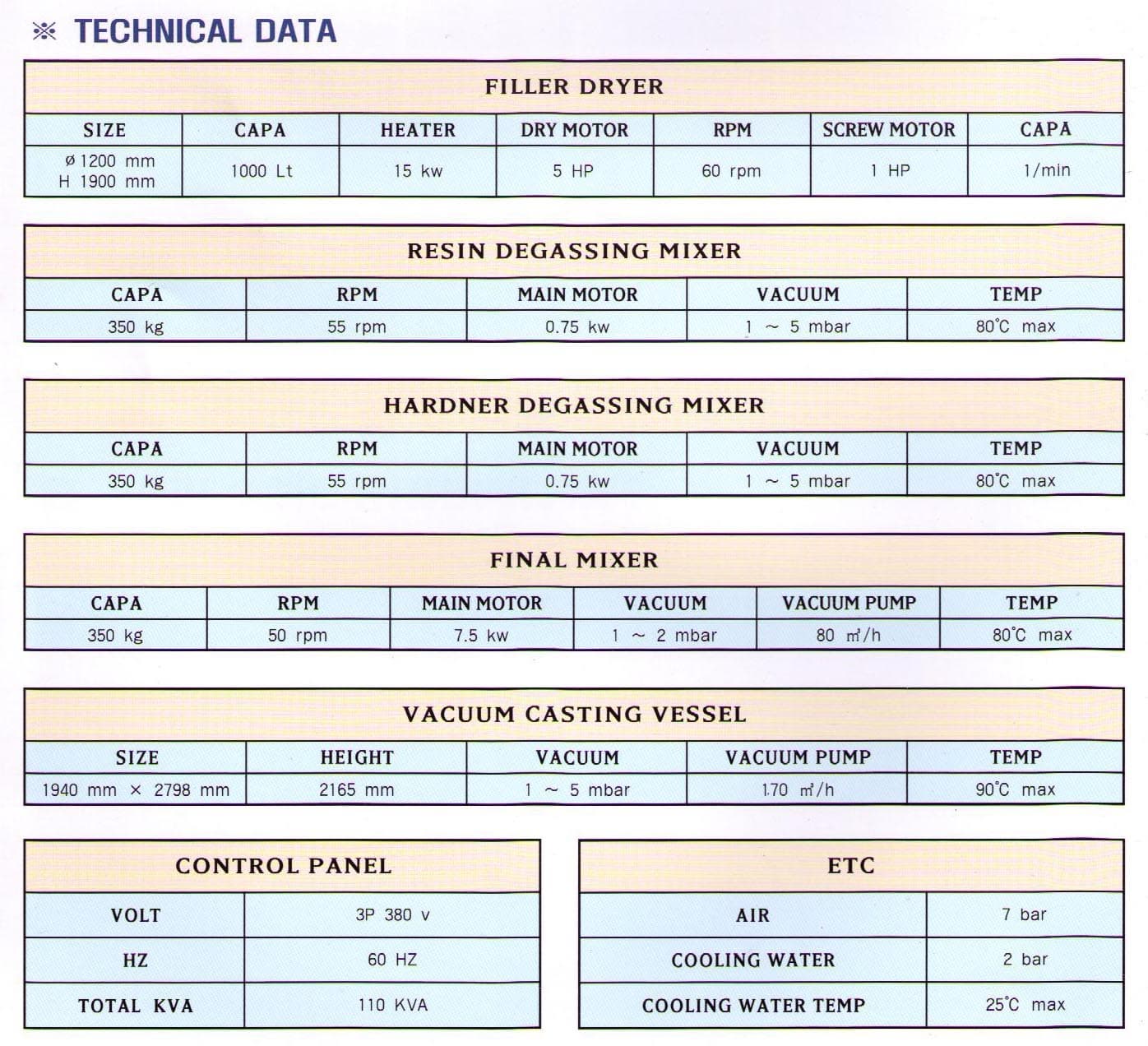

VACUUM CASTING PLANT SPECIFICATION (Thin film degassing type)

Capacity : 3 charge ~ 4 charge/8hours

1. Resin & Hardner Storage TANK A. TANK : 300 Liter x 2 sets B. HEATING UNIT : 5Kw x 2 sets

2. Filler Storage Vessel A. TANK : 2000 Liter x 1 set

3. Filler Dryer A. TANK : 200 Liter B. VACUUM : 400 Torr

4. Resin Filler & Hardner Filler Mixing System A. TANK : 300 Liter x 2 sets B. Heating unit : 5Kw x 2 sets

5. Flexiblizer, Accelerator Pre-mixer A. TANK : 80 Liter x 1 set B. Load Cell

6. Color Pre-Mixer A. TANK : 20 Liter B. Bend Heater : 2Kw

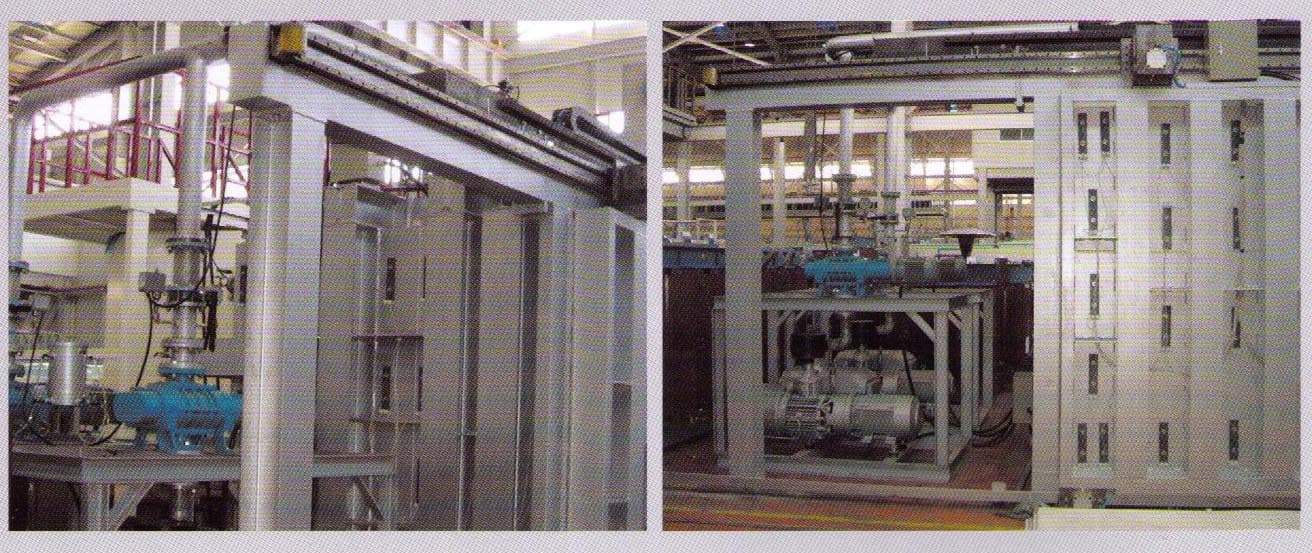

7. Final-mixer (Thin Film Degassing Mixer) A. TANK : 300 Liter x 1 set B. Heating Unit m/5x C. 80 degree celsius 24hour continuous operation

8. VACUUM Vessel System A. FRAME 1 set : 2600(W)×2570(D)×2500(H) B. CLAMP UNITS C. DOOR D. HOIST RAIL E. HOIST UNITS F. GEARD MOTER G. RAIL : 12Kg x 2 Rails H. Heating System : 5 side heating exclude bottom side

9. VACUUM System (2 sets) A. VACUUM PUMP (1200m3/hour Booster with Vaine 3500L/min) B. VACUUM PUMP (720m3/hour Booster with Vaine 3200L/min) C. VACUUM PUMP (200m3/hour Dry Pump)

10. Electric Control System A. GRAPHIC PANEL BOX ( 380V 60HZ 3phase) B. CPU, CRT DISPLAY (220V 60HZ 1phase) C. OP BOX(220V 60HZ 1phase )

11. Structure W(7400)×D(6300)×H(4000)

12. Piping with Valve A. Valves (SUS,SS, AUTO V/V, MANUAL V/V) B. Piping (SUS,SS)

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- SK Hong

- Address

- 102-304, Kolon 73, Samsundong-4ga, Seongbook-gu, Seoul, Korea 136-760

- Product Category

- Aluminum Composite Panels,Other Construction Material Making Machinery,Other Machinery & Industry Equipment

- No. of Total Employees

- 1-50

- Company introduction

-

ALU Korea is the exporter and technical service provider for various kinds of industrial machinery. We supply brand-new industrial machines, spare parts, raw material, maintenance and upgrade service, other technical service and consulting. Our business goal is customer satisfaction for which we are endeavouring to provide quick response, zero defect, indiscrete full service to our customers.

- Main Markets

-

Argentina

Argentina

Brazil

Brazil

Cambodia

Cambodia

Croatia

Croatia

Czecho Republic

Czecho Republic

Egypt

Egypt

Hungary

Hungary

India

India

Indonesia

Indonesia

Iran

Iran

Kuwait

Kuwait

Mexico

Mexico

Mongolia

Mongolia

N.Zealand

N.Zealand

Oman

Oman

Paraguay

Paraguay

Peru

Peru

Philippines

Philippines

Poland

Poland

Qatar

Qatar

Romania

Romania

Russia

Russia

Saudi Arabia

Saudi Arabia

South Africa

South Africa

Spain

Spain

Thailand

Thailand

Tunisia

Tunisia

Turkey

Turkey

U.A.E.

U.A.E.

Ukraine

Ukraine

Uruguay

Uruguay

Viet Nam

Viet Nam

Yemen

Yemen

Yugoslavia

Yugoslavia

Zimbabwe

Zimbabwe

- Main Product

Related Products

Airless Pump (Ratio 63:1 Airless Pump)

AIS3000 HD

_2.jpg)

Micro Probe System (MPS-PTH)

AIRLESS PUMP- YL 731

Torrington Bearing

South Korea

South Korea