CleanRoom Garments

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Safety Clothing

Silitex Purification Co., Ltd.

- Verified Certificate

-

16

| Product name | CleanRoom Garments | Certification | - |

|---|---|---|---|

| Category | Safety Clothing | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Introduction

As the manufacturer of High technical performance industrial fabrics , Silitex has been also a specialist for last 20years in high technology cleanroom and clean area garments.

On continual input into garment design to meet the changing demands and specifications within the cleanrooms with our own made highest quality fabrics, we continue to supply garments to reach the most critical standards and norms.

Our cleanroom garment collection provides comfortable, easy-to-maintain High Tech garments for the micro-electronic, pharmaceutical, automotive, optical and food industries together with outstanding wear performance for cleanroom classes 1 to 100,000.

Only the highest quality fabrics and the most up-to-date developments are used and based on six key criteria:

- High durablity,

- ESD performance,

- Universal sterilsation protection( Steam-ETO-Gamma- radiation)

- Particle barrier,

- Low linting,

- Comfort

A special processing technique, engineered by Silitex, is used to prevent fraying. Seamed, sewing threads and accessories fully meet the requirements of cleanroom users. Our cleanroom garments meet the latest world standards and norms for cleanroom garments. For every cleanroom application, Silitex offers the best solution

1. The standard type

In a cleanroom environment, workers are the most important source of contamination. The continual renewal of the epidermis produces dead cells which can be carriers of bacterial. Our cleanroom garments hold these cells and other particles inside the garment to prevent contamination of the cleanroom itself.

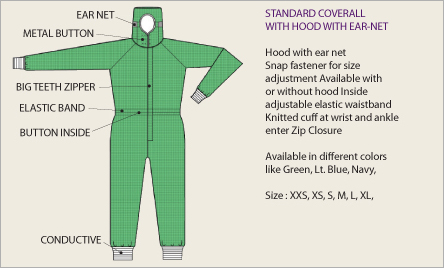

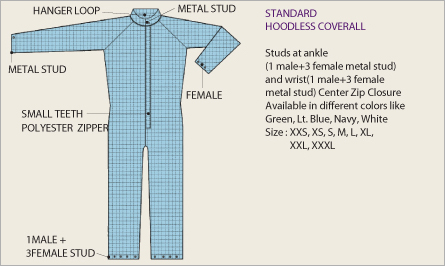

- A. Coverall

. snap button at wrist and ankle

. thumb-hoop

. metal studs at the inner and outer-leg to attach the boots

. elastic in the back - B. Coverall with hood

. styled comfort fit

. knitted polyester cuffts at the sleeves

. knitted polyester cuffts at the leges

. elastic in the waist

. metal studs at the hood to attach a face mask

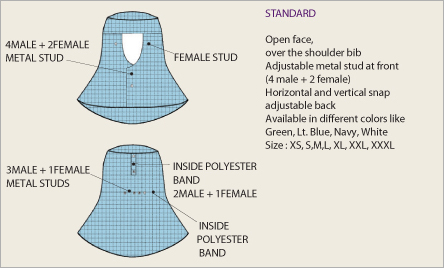

. ribbon at the back to adjust the hood - C. Closed hood

. ribbons at the bottom to avoid the hood lifting

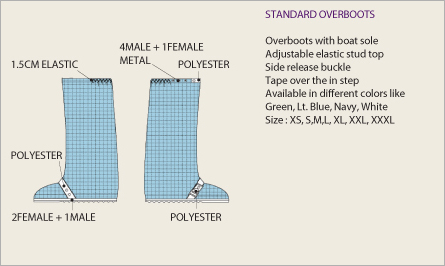

. elastic and buckle at the back to tighten the hood. - D. Boots with boat sole

. closure with 2 x 1 piece plastic buckle

. elastic at the top

. metal studs at the sides to attach to the coverall - E. Boots with flat sole

. closure with 2 x 2 piece plastic buckle

. with ribbon + metal studs at the top of the boot

. elastic at the top to tighten the boot around the calf - F. Face mask

. with metal studs to attach to the hood

2. Garment options

The correct garment design and fit are as important in defining the performance as the fabric properties. Silitex offer different accessories all of which provide complete body cover without particle leakage or blow-out.

- 2-1. Garment option for hoods and caps

A. Metal studs as front closure

B. Metal studs to adjust the hood

C. Metal studs to attach the face mask

D. Face mask

E. Polyester ribbon at the back to adjust the hood.

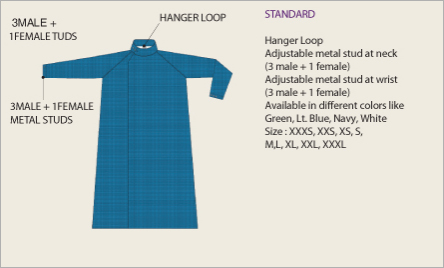

F. Polyester ribbon with the buckle at the back to adjust the hood - 2-2. Garment options for coveralls

Sleeves

A. Finished with knitted polyester cuffs

. Also available in navy blue and in anti-static version

B. Finished with metal studs( 3 male and 1 female )

C. Finished with elastic

Legs

D. Finished with knitted polyester cuffs

. Also available in navy and in anti-static version

E. Finished with metal studs ( 3male and 1 female)

F. Finished with elastic

Elastic in back

G. With fixed elastic in the back

H. With adjustable elastic in the back

I. With elastic in the waist

- 2-3. Garment options for boots and overshoes

Top of the boot

A. Elastic

B. Ribbon + studs in combination with elastic

C. Elastic at the back and ribbons at the front Front closure

D. Zipper

E. One piece metal buckle

F. One piece plastic buckle

G. Two piece plastic buckle

. Also available in gamma resistant compound

Soles

H. Boat sole

. Dupont Hypalon Rubber sole, steam and ETO resistant.

. Excellent durability after several sterilizations

I. Flat sole

. Dupont Hypalon Rubber sole, steam and ETO resistant.

. Excellent durability after several sterilizations

3. ESD

Silitex ESD garments have been designed and engineered to provide optimum protection to ESD overstress discharge within the most critical areas of microelectronic component manufacturer and assembly.

Silitex garments meet all recognized international standards for ESD.

- ESD Dust coat

- 1 chest pocket

- 1 inside chest pocket

- 2 hip pocket

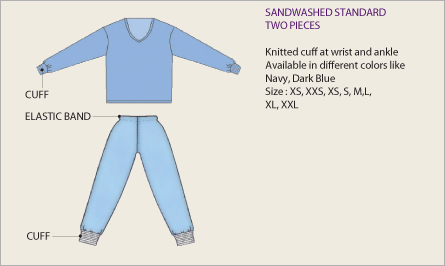

4.Food Procesing

To guarantee an optimal hygiene and high quality products in an industrial food production environment, it's necessary. For cleanarea ( Class 10,000~100,000) garments. Silitex Cleanarea garments are specially designed to prevent contamination of your product and your clean environment.

A. Hat finished with knitted fabric

B. Long-sleeve tunic with V-neck

- extra protection flap

- metal studs at the sleeve to tighten the sleeve around the wrist

C. Trousers

- metal studs at the legs to tighten the trousers around the ankle

- elsatic in combination with flap and metal stud

- practical front pocket with flap and metal stud

5. CleanRoom classes

ISO cleanroom standards 14644-1 versus US FED STD 209E celanroom standard versus EU GMP

| ISO Class | FED STD Class | EU GMP | Particles per m2 | |||||

| 0.1 µm | 0.2 µm | 0.3 µm | 0.5 µm | 1 µm | 5 µm | |||

| ISO 3 | 1 | 1,000 | 237 | 102 | 35 | 8 | ||

| ISO 4 | 10 | 10,000 | 2,370 | 1,020 | 352 | 83 | ||

| ISO 5 | 100 | Class A | 100,000 | 23,700 | 10,200 | 3,520 | 832 | 29 |

| ISO 6 | 1,000 | 1,000,000 | 237,000 | 102,000 | 35,200 | 8,320 | 293 | |

| ISO 7 | 10,000 | Class B | 352,000 | 83,200 | 2,930 | |||

| ISO 8 | 100,000 | Class C | 3,520,000 | 832,000 | 29,300 | |||

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- CHUNG MOON SUK

- Address

- 92-30 Imsu-dong, Gumi-si, Gyeongsangbuk-do, Korea

- Product Category

- Industry Fabric,Other Fabric

- No. of Total Employees

- 1-50

- Company introduction

-

Silitex have been supplying a variety of customers in 40 countries with these superior quality products over last twenty years.

Our specialty lies in designing and developing fabrics with exactly right style, comfort and performance properties demanded by our customer across a wide spectrum of end uses.

Further to this, we always put more endeavor and guarantee to make our customers satisfied with quality, price, delivery and service by producing and providing the new development pursuing after customer's needs and satisfaction.

- Main Markets

-

Denmark

Denmark

Mexico

Mexico

Spain

Spain

U. Kingdom

U. Kingdom

U.S.A

U.S.A

- Main Product

Related Products

Guardman G-1, G-2 Coveralls

LB2-202

Cleanroom cap, ESD cap, cleanroom anti-static cap----Lowest price in market, factory direct

Safety Vest with LED

Guardman FR Coverall (Flame resistant)

South Korea

South Korea