Parts and Accessories for Maintenance

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Concrete Machinery

Samil Heavy Industries Company

- Verified Certificate

-

12

| Product name | Parts and Accessories for Maintenance | Certification | - |

|---|---|---|---|

| Category | Concrete Machinery | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

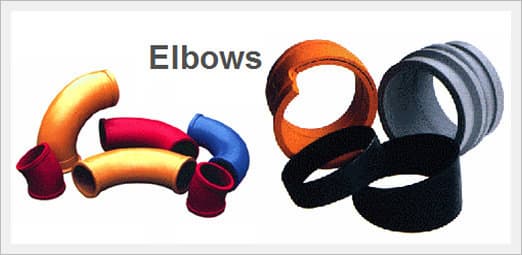

1) Casted on Elbow (5' Series)

|

Diameter(Inch)

|

Description

|

P/Number

|

Size

|

Remarks

|

|

125A-5'

|

90' boom elbow

|

DS125-5-90N

|

125-148-275r

|

G x 120MnCr13.2

|

|

125A-5HE

|

90' boom elbow

|

DS125-5-90H

|

119-157-275r

|

G x 120MnCr13.2

|

|

125A-5'

|

45' boom elbow

|

DS125-5-45N

|

125-148-275r

|

G x 120MnCr13.2

|

|

125A-5HE

|

45' boom elbow

|

DS125-5-45H

|

119-157-275r

|

G x 120MnCr13.2

|

|

125A-5'

|

30' boom elbow

|

DS125-5-30N

|

125-148

|

G x 120MnCr13.2

|

|

125A-5'

|

20' boom elbow

|

DS125-5-20N

|

125-148

|

G x 120MnCr13.2

|

|

125A-5'

|

15' boom elbow

|

DS125-5-15N

|

125-148

|

G x 120MnCr13.2

|

|

125A-5'

|

14' boom elbow

|

DS125-5-14N

|

125-148

|

G x 120MnCr13.2

|

|

125A-5'

|

10' boom elbow

|

DS125-5-10N

|

125-148

|

G x 120MnCr13.2

|

6' Series

|

Diameter(Inch)

|

Description

|

P/Number

|

Size

|

Remarks

|

|

150A-6'

|

90' elbow (G.PM)

|

DS150-6-90A

|

275R x 90' M.FE

|

G x 120MnCr13.2

|

|

150A-6'

|

90' elbow (A.PM)

|

DS150-6-90B

|

275R x 90' M.FE

|

G x 120MnCr13.2

|

|

150A-6'

|

90' elbow (A.SW.O)

|

DS150-6-90C

|

275R x 90' M.FE

|

G x 120MnCr13.2

|

|

150A-6'

|

90' elbow (SW.N)

|

DS150-6-90D

|

90' +SW Type

|

G x 120MnCr13.2

|

|

150A-6'

|

90 elbow

|

DS150-6-20E

|

90' 375R

|

G x 120MnCr13.2

|

2) Special Elbow

|

Diameter(Inch)

|

Description

|

P/Number

|

Size

|

Remarks

|

|

125A-5'

|

45' boom elbow

|

DS125-5-45S

|

125-148

|

Harden pipe Hi frequemcy wave heating pipe & liner input

|

|

125A-5'

|

30' boom elbow

|

DS125-5-30S

|

125-148

|

|

|

125A-5'

|

20' boom elbow

|

DS125-5-20S

|

125-148

|

|

|

125A-5'

|

15' boom elbow

|

DS125-5-15S

|

125-148

|

|

|

125A-5'

|

14' boom elbow

|

DS125-5-14S

|

125-148

|

|

|

125A-5'

|

10' boom elbow

|

DS125-5-10S

|

125-148

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Hyeyeong Joung

- Address

- 12 Daedong and store, 193 Sambang-dong, Gimhae-si, Gyeongsangnam-do, Korea

- Product Category

- Other Machinery & Industry Equipment

- Year Established

- 2010

- No. of Total Employees

- 1-50

- Company introduction

-

Samil Heavy Industries was established in 1996. We are a manufacturer of concrete pumping equipment. As you know well, concrete boom pump is mainly used in construction (building) work site and they are so big and heavy, and very difficult and dangerous to drive. These technology intensive machines have high labor costs and logistical costs. So, the manufacture and export in Korea don’t have price competitiveness. To have competitiveness, we are very interested in the support of techniques and collaboration for local assembly.Our products consist of steel structure(boom and turning base), system(hydraulic, electric) and truck. Price configuration is steel structure 40%, system 25%, truck 25% and others 10%. Technique configuration is steel structure 65% and system 35%. In case of this equipment, it’s very difficult to design the structure with new standard. In addition, this work have greater risk for the verification and responsibility for safety of new design. We have supplied the structures in component state and supported technique transfer to 6 Korean companies(it’s difficult for them to make the structure directly) and around 20 overseas companies(India, Israel, China, Australia, etc..) with conditions to suit their needs based on long experience and excellent design skills(we have system and ability to be able to design, make and verify the structure newly). In case of this equipment, it’s very difficult to design the structure with new standard. In addition, this work have greater risk for the verification and responsibility for safety of new design. We have supplied the structures in component state and supported technique transfer to 6 Korean companies(it’s difficult for them to make the structure directly) and around 20 overseas companies(India, Israel, China, Australia, etc..) with conditions to suit their needs based on long experience and excellent design skills(we have system and ability to be able to design, make and verify the structure newly).On 15 Apr. 2011, we made a contract for export of engineering techniques with Greaves Cotton Ltd of India(primary USD2million & secondary USD1.5million). Now, around 80% of secondary project is underway favorably. When this contract is finished, we expect the export of parts of around USD80million~100million level for 5 years. At present, we are in negotiation and propulsion of similar size of contract with some overseas companies(HAINUO of China, some companies of Canada and Brazil, etc..).Regarding some of techniques for manufacture of concrete pump truck(CKD assembly production in local company), we have supported for free(but, actual costs should be borne by local company.).

- Main Markets

-

South Korea

South Korea

- Main Product