Cleanser (I.F.C)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Detergent Raw Materials

YJEstec CO., LTD.

- Verified Certificate

-

16

| Product name | Cleanser (I.F.C) | Certification | - |

|---|---|---|---|

| Category | Detergent Raw Materials | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Specification

|

Item / Model

|

IFC-3137

|

IFC-3645

|

IFC-36110

|

IFC-4675

|

IFC-5175

|

IFC-5675

|

|

Temperature range (°C)

|

550°C

|

|||||

|

Load capacity (ℓ)

|

11

|

16

|

38

|

45

|

58

|

85

|

|

Power consumption (kw)

|

8

|

10

|

15

|

14

|

18

|

22

|

|

Air consumption (ℓ/min)

|

60~130

|

60~150

|

160~300

|

150~300

|

150~450

|

220~500

|

|

Air pressure (Kg/cm2)

|

2~10

|

|||||

|

Outer dimensions (mm)

|

625 x 650 x 900

|

690 x 890 x 900

|

690 x 890 x 1650

|

790 x 1050 x 1350

|

860 x 1250 x 1400

|

|

|

Power supply option

|

220V / 380V 440V. 3ph. 50~60Hz

|

|||||

|

IFC weight (Kg)

|

98

|

180

|

240

|

450

|

880

|

|

- Basic items: Cleaning equipment, basket, Medium, Cyclone/ Recovery Bin, Adapter Damper

- Optional items: To be purchased separately

- There are various models for customer uses and made to order is also available

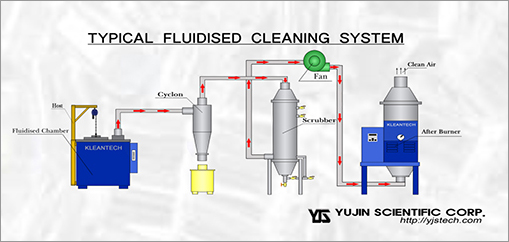

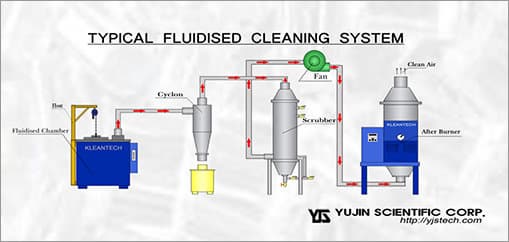

- Cleaning furnace: Cleaning area to clean residue of precise parts

- Cyclone: Centrifugal precipitator to collect particles like carbon scattering in the air from first precipitator.

- Scrubber: Gas cleaner which neutralizes the toxic gas by liquefaction.

- After Burner: Re-combustion unit to release residual toxic gas as clean gas by combustion with oxygen and LPG.

Problems of existing cleaning method

|

Cleaning method

|

Problems

|

|

Chemical processing

|

It is possible to clean only soluble plastics. It requires a lot of time to clean. Solvent, TCE, CFC

|

|

High-temperature incinerator

|

It takes longer time due to low heat conductivity. Cleaned mechanical parts may be twisted. It cannot be used for precise mold.

|

|

Tool or wire brush

|

It is the most underdeveloped cleaning method. It needs long working time and mold wear or damage is considerable.

|

|

High temperature salt bath type

|

It needs a lot of maintenance cost by high price salt medium and continuous power supply to prevent coagulation and there is a risk of burns caused by explosion. It also may cause corrosion or thermal deformation.

|

|

Vacuum type

|

Facility cost is big and there is a risk of explosion.

|

|

Ultrasonic type

|

It is the most popular method. It is impossible to remove residual polymer.

|

|

Dry ice type

|

Surface attachment concerned. It is impossible to use precise mold.

|

I.F.C. Cleaning coverage

|

Field

|

Parts

|

|

Fiber

|

Distributor plates, Filter elements, Mixers, Spinning Gear pumps, Spin packs, Spinnerets. etc.,

|

|

Polymer extrusion

|

Housing, Extrsion heads, Die plates, Melt pumps, Breaker plates, etc.,

|

|

Film

|

Die plates, Distributors, Filters, Mixers, Screws, Screw elements, etc.,

|

|

Injection molding

|

Dies, Hot runners, Needle valve nozzles, etc.,

|

|

Incineration temperature

|

Poltmer to be removed

|

|

350°C

|

Rubber deboning Polycarbonate

|

|

440°C~450°C

|

Polyurethane

|

|

425°C~500°C

|

Polypropylene

|

|

450°C~480°C

|

Ethylene methacytic

|

|

450°C

|

Nylon, Polystyene, Styrene, Fluoropolymers

|

|

450°C~500°C

|

Polyethylene, PVC, Organic matter/oil/grease

|

|

450°C~500°C

|

Paint, Teflon, Engineering plastics.

|

|

550°C

|

Silicone / rubber

|

I.F.C. with excellent cleaning effect and economics

Currently, plastic products are widely used in daily life and overall industry. According to this, manufacturers need more complicated and precise parts than before. They are struggling in cleaning precise parts such as Dies, Molds and Spinnerets used essentially in plastic manufacturing process. Also existing cleaning method needs a lot of manpower and time, wear of corrosion of the parts and it causes environmental contamination. To solve these problems, we have developed an industrial mold cleaner using Fluidized Bed Principle. For last 30 years, many larger domestic companies and overseas companies have been using our I.F.C.

I.F.C. Principle and Operation

I.F.C. is a cleaning equipment using Fluidized Bed Principle to clean out the residue in precise parts such as Dies, Nozzles, Screws, Breaker plate or Molds which are difficult to be cleaned by hands more efficiently.

Before operating I.F.C. cleaning equipment, Thermal Medium is filled in cleaning furnace. Fluid is heated up to the temperature (400~ 500 ℃) which is the most proper to clean as compressed air is injected into cleaning furnace from air supplier. At this time, a Fluidized Bed like boiling liquid is formed as powder articles (fluid) float. If putting things to be cleaned in a basket into this Fluidized Bed, cleaning is completed around in 30~50 minutes and toxic gases generated during cleaning work are released as clean gases passing through re-combustion process.

- Thermal Medium: It is most suitable as flow medium in the aspects of thermal conductivity, temperature stability, uniformity and environmental protection. It is very sage as it is inactive.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- LEE SHIN HYUNG

- Address

- 310-2, Yadong-dong, Paju-si, Gyeonggi-do, KOREA

- Product Category

- Other Plastic Product Making Machinery

- No. of Total Employees

- 1-50

- Company introduction

-

Dear prospective customers, We are pleased to get this chance to introduce ourselves to you who might be our valuable customers in the future. We have two business divisions. One is to manufacture industrial cleaning machines. The other is trade business to sell our customers in the world Industrial Molds & Dies Cleaning System We have been focusing on industrial molds,Dies cleaning system over 20 years. Now, we manufacture the industrial fluidized cleaning system which removes polymeric residues, coatings, contaminations and other organic materials from metal parts and extruder hardware. We are exporting the industrial fluidized cleaning system to many companies all over the world. Importer We are one of the leading importers dealing with some kinds of test instruments that would be handled most of the laboratories and the industrial fields, such as calibrators, micro-ohmmeters, furnaces, water vapor testers, and so on. Since 1979, we have endeavored to make our customers satisfied and gained a good reputation as steady supplier of instruments of the highest quality and as the best manufacturer of industrial cleaning machines. We will be a company to promise you best quality, accurate deliver and reasonable price with long experience and field knowhow. Thank you for your attention and we sincerely look forward to serving you in the nearest future. Best Regards,

- Main Product

Related Products

labsa 96%

Sodium Lauroyl Glutamate

LABSA 96%

alkyl polyglucoside

AOS 35% (Sodium C14-C16 Alpha-Olefin Sulfonate Liquid)

South Korea

South Korea