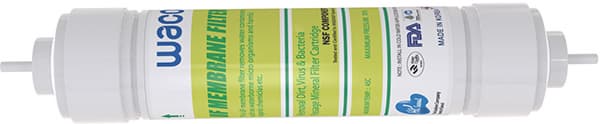

Ultrafiltration Membrane FILTER

Ultrafiltration Membranes

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- L/C,T/T

- Production method

- Available,OEM

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Water Softeners

WACO Corp.

- Membership

- VIP

- Recent Visit

- Dec 30, 2024

- Country / Year Established

-

South Korea

/

2004

South Korea

/

2004

- Business type

- Manufacturer

- Verified Certificate

-

17

| Product name | Ultrafiltration Membrane FILTER | Certification | - |

|---|---|---|---|

| Category | Water Softeners | Ingredients | - |

| Keyword | uf membranes , water filter , uf membrane in water treatment , uf drinking water system | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | 50000 |

| Supply type | Available,OEM | HS code | - |

Product Information

Characteristics of Ultrafiltration Membrane

UF membrane with pore sizes in the range of 0.03 to 0.05 micron typically remove high molecular-weight substances, colloidal materials, and organic and inorganic polymeric molecules, bacteria except minerals. Low applied pressures are sufficient to achieve high flux rates from an ultrafiltration membrane.

Flux of a membrane is defined as the amount of permeate produced per unit. our UF filter shows

excellent water permeability. The flux varies between 50 and 200 GFD at an operating pressure of about 50psig in contrast, Reverse osmosis membranes only produce between 10 to 30GFD at 200 to 400psig.

Quality properties of resistance to acid and alkali, high flow-rate, non-toxicity, no-taste and stable performance.

Advantages:

1.Highthroughputofproduct

2.Lowprocesscost

3.Easeofscale-up

Application:

1.Fractionationofproteinsandnucleicacids

2.Concentration of macromolecules

3.Desalting,i.e.removal or salts and other low molecular weight compounds from solution of macromolecules

4.Removal of cells and cell debris from fermentation broth

5.Virusremoval fromtherapeuticproducts

Ultrafiltration Membranes

Basically UF membrane modules come in plate-and frame, spiral-would, and tubular

configurations.

All configurations have been used successfully in different process applications. each configuration is specially suited for some specific applications and there are many applications where more than one configuration is appropriate. For high purity water, spiral-wound and capillary configurations are generally used. The configuration selected depends on the type and concentration of colloidal material or emulsion.

Factors Affecting the Performance of Ultrafiltration.

Flow Across the Membrane Surface.

The permeate rate increases with the flow velocity of the liquid across the membrane surface. Higher flow also means higher energy consumption and larger pumps. Increasing the flow velocity also reduces the fouling of the membrane surface. Generally, an optimum flow velocity is arrived at by a compromise between the pump horsepower and increase in permeate rate.

Operating Pressure.

Permeate rate is directly proportional to the applied pressure across the membrane surface. However, due to increased fouling and compaction, the operating pressures rarely exceed 100psig and are generally around 50psig. In some of the capillary-type ultrafiltration membrane modules the operating pressures are even lower due to the physical strength limitation imposed by the membrane module.

Flow Across the Membrane Surface.

Permeate rates increase with increasing temperature. However, temperature generally is not a controlled variable. It is important to know the effect of temperature on membrane flux in order to distinguish between a drop in permeate due to a drop in temperature and the effect of other parameters.

Membrane Materials

A variety of materials have been used for commercial ultrafiltration membranes, but polysulfone and cellulose acetate are the most common. For high purity water applications the membrane module materials must be compatible with chemicals such as hydrogen peroxide used in sanitizing the membranes on a periodic basis.

Pressure Resistance

1. Applied pressure: 0.5~4 kgf/cm2

2. Resident time at each pressure: 5 minutes

3. Maximum operating pressure: 4 kgf/cm2

Particle Size Cut Off Character

1. Standard particles: Polystyrene latex bead(Sigma, Mean dia.: 0.03, 0.05 um)

2. Pressure: 1 kgf/cm2

3.Analysis: UV Spectrometer(∧=320 nm)

4. Influent: 100 ppm aqueous suspension

5. Effluent: 7.5 ppmfor 0.03 um(92.5 % rejected) , 1.5 ppmfor 0.05 um(98.5 % rejected)

1. Bacteria: E. Coli

2. Influent: 725 CFU/ml

3. Effluent: Negative(0 CFU/ml, 100% Reduced)

B2B Trade

| Price (FOB) | Negotiable | transportation | Ocean Shipping |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Yong Sung, Shin

- Address

- 10,#A-301, Nowon-gu, Seoul, Korea

- Product Category

- Water Dispensers & Purifiers,Water Softeners,Water Treatment

- Year Established

- 2004

- No. of Total Employees

- 1-50

- Company introduction

-

We, WACO Corp. are thespecialized manufacturer and exporter of Water purifiers for household andWater purification systems for Commercial and Industrial use based on ourcontinuous study and investment for the products. And we have secured thesuperior competitive power while exporting our goods to over 50 countries sinceestablished.

In addition, we are the enterprise of"KOTRA Global Brand Company" by KOTRA (Korea Trade-InvestmentPromotion Agency) and "Hi Seoul Brand" who is selected by SeoulMetropolitan Government and has the most advanced technology and the qualitycertificates for the goods. And we are trying to open the healthy cultural lifefor our worldwide customers with the high quality and the advanced technology.The worldwide customers acknowledge that Hyundai Wacor Tec. Co., Ltd. is thesymbol of Korea in the field of Water purifiers and Water purification systems.

We will be continuously trying to developall our products as a worldwide leader of the manufacturers of water purifiersand water purification systems. We will do our best to let the worldwidecustomers know the superior technology and design of Korea as Creation andGrowth that Taeguek symbol also means in Taeguek-Flag. And we will try tobecome a reliable enterprise who always develop the quality of the goods.

All products and related products are designed and manufactured specifically by WACO Corp. in this catalogue showcase. Our company continues the healthy growth ever aiming for the best quality and prioritizing the trust with customers. Also we will keep exerting every effort to meet customers' needs by focusing on the technology development in order to cope with its industry innovation in advance. We ask your continuous attention and encouragement.

Our company policy is to research and to develop our products

continuously.

Some contents of this catalogue can be changed to improve the quality and design of products without notice.

*Copyright© All Rights Reserved by WACO Corp.

All rights reserved and unauthorized copy is prohibited.

- Main Markets

-

Australia

Australia

Chile

Chile

Spain

Spain

Thailand

Thailand

U.S.A

U.S.A

- Main Product

_2.jpg)

_2.jpg)