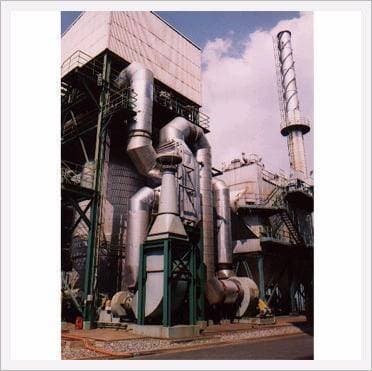

Hot Oil Heater

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Electric Heaters

Kang Won N.T.S. Co.,Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

16

| Product name | Hot Oil Heater | Certification | - |

|---|---|---|---|

| Category | Electric Heaters | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Descriptions

Hot oil heater safely supplies low pressure oil for high temperature processes. Moreover, this Boiler is mainly used for chemistry, petrochemical, textile, plastics, paint and rubber industries, that consists of coil type with excellent pertinency in performance and high efficiency.

Struccture & Title

Use

Hot Oil Heaters are operating in various industries, satisfying clients' requirements.

Water is not always the best heat transfer medium. In many districts in the world where is short of water, hot oil heaters are widely used in indirect heating. In korea, hot oil heaters are also operating in various fields making good use of their merits.

IN hot oil Heating system, heat energy is transferred in liquid phase. For heat recovery a hot oil heater is favorably employed. it can be employed in a wide range of indirect heating, from 0°C, High temperature is obtained under comparatively low pressure.

|

Chemicals |

Polymerization, condensation & addition units distillation, rectification & melting unit heat retaining(for asphalt, etc) |

|

Oil and Fats |

Fatty acid distillation units esterification units, oil & fats decomposition units hydrogenation plants, vacuum deodorization plants distillation, rectification & condensation units |

|

Plastics & Rubber |

Hot press, calender, extruders, vulcanizing molders resin thermosetters |

|

Petroleum |

Forced heat retaining(for tank and fuel oil heating) synthesizing and reacting units, LPG vaporizers distillation and plants, LNG separators |

|

Fiber |

Polymerization reactors, dryers heat setters, dry cleaning embossing rollers coating machines, spreaders |

|

Atomic Energy |

treating units for used unclear fuel |

|

Paper |

Hot melters, coating machines corrugating machines, dryers |

|

Wood |

Hot press, dryers |

|

Metals |

Picking and plating machines heat treatment units coating machines, electrode manufacturing units |

|

Coating |

Baking coat dryer |

|

Construction |

Asphalt melting & heating machines, road snow melters concrete block curing tanks |

|

Air Conditioning |

Radiant heaters, heaters/coolers for buildings |

|

Other uses |

Sea water desalting plants Tank heaters for ship |

The system is free from corrosion. Hot oil can be used in cycle in a closed system, so work for feeding and discharging water is unnecessary. Uniform heating and cooling and accurate temperature control can be achieved

Standard Specification & Sketch

KWB Coil Pack Standard Flow

Basic Flow Sheet1(Vapor Phase-Thermal Oil)

Basic Flow Sheet2(Liquid Phase-Thermal Oil)

Style

| TYPE | ||||||||||

| DECRIPTION |

KCP-30 |

KCP-40 |

KCP-50 |

KCP-80 |

KCP-100 |

KCP-150 |

KCP-200 |

KCP-250 |

||

|

Standard Output |

103Kcal/H | 300 | 400 | 500 | 800 | 1000 | 1500 | 2000 | 2500 | |

|

MAX. Operating Pressure |

kg/cm2G | 10 | ||||||||

|

MAX. Operating Temperature |

°C | 350 | ||||||||

|

Dimensions |

A |

mm | 1260 | 1290 | 1340 | 1895 | 1945 | 2140 | 2340 | 2450 |

|

B1 |

mm | 860 | 885 | 910 | 1195 | 1235 | 1340 | 1455 | 1510 | |

|

C |

mm | 3150 | 3350 | 3550 | 3500 | 3700 | 4350 | 4800 | 5350 | |

|

H1 |

mm | 4150 | 4350 | 4550 | 4500 | 4700 | 5350 | 5800 | 6350 | |

|

H2 |

mm | 5200 | 5400 | 5600 | 5600 | 5800 | 6400 | 6900 | 7500 | |

|

Therm Oil |

Connection DIA. |

(A) | 50 | 65 | 65 | 80 | 100 | 125 | 150 | 150 |

|

Flow Rate |

m3/H | 20 | 28 | 35 | 56 | 70 | 105 | 140 | 175 | |

|

Pressure Loss |

mH | 1.2 | 0.6 | 1.1 | 1.1 | 2.0 | 2.3 | 2.1 | 1.7 | |

|

Holding-up Volume |

m3 | 0.26 | 0.26 | 0.31 | 0.62 | 0.76 | 1.35 | 2.1 | 2.3 | |

|

Self Weight in Operation |

TON | 1.5 | 1.7 | 2 | 3.1 | 3.7 | 5.2 | 6.5 | 8 | |

|

Burner |

Fuel |

DIESEL, GAS | HEAVY, GAS | |||||||

|

COMB.(Max) |

104Kcal/H | 36 | 48 | 60 | 96 | 120 | 180 | 240 | 300 | |

|

Control |

ON, OFF, 3POSITION | PROPORTIONAL | ||||||||

|

Stack |

Inside Diameter |

mm | 250 | 300 | 350 | 350 | 400 | 500 | 600 | 700 |

|

Height |

m | 9 | 9 | 9 | 9 | 12 | 12 | 12 | 12 | |

|

|

TYPE | |||||||||

| DECRIPTION |

KCP-300 |

KCP-400 |

KCP-600 |

KCP-800 |

KCP-1000 |

KCP-1200 |

KCP-1500 |

KCP-2000 |

||

|

Standard Output |

103Kcal/H | 3000 | 4000 | 6000 | 8000 | 10000 | 12000 | 15000 | 20000 | |

|

MAX. Operating Pressure |

kg/cm2G | 10 | ||||||||

|

MAX. Operating Temperature |

°C | 350 | ||||||||

|

Dimensions |

A |

mm | 2600 | 2745 | 3100 | 3400 | 3510 | 3800 | 4150 | 4400 |

|

B1 |

mm | 1610 | 1685 | 1885 | 2060 | 2115 | 2280 | 2455 | 2605 | |

|

C |

mm | 5700 | 6550 | 6400 | 7700 | 8500 | 9100 | 10150 | 11350 | |

|

H1 |

mm | 6700 | 7550 | 7400 | 8700 | 9500 | 10100 | 11150 | 12350 | |

|

H2 |

mm | 7800 | 8650 | 8500 | 9800 | 10600 | 11200 | 12500 | 13500 | |

|

Therm Oil |

Connection DIA. |

(A) | 200 | 200 | 250 | 300 | 300 | 350 | 350 | 400 |

|

Flow Rate |

m3/H | 210 | 280 | 420 | 560 | 700 | 840 | 1050 | 1400 | |

|

Pressure Loss |

mH | 2.2 | 2.3 | 1.2 | 1.3 | 2.3 | 1.9 | 1.1 | 2.4 | |

|

Holding-up Volume |

m3 | 3.1 | 4.4 | 6.8 | 9.05 | 9.75 | 14.13 | 21.5 | 26.6 | |

|

Self Weight in Operation |

TON | 10.5 | 13 | 19 | 25 | 29 | 36.4 | 47.8 | 58.2 | |

|

Burner |

Fuel |

HEAVY OIL, GAS | ||||||||

|

COMB.(Max) |

104Kcal/H | 360 | 480 | 720 | 960 | 1200 | 1440 | 1800 | 2400 | |

|

Control |

PROPORTIONAL | |||||||||

|

Stack |

Inside Diameter |

mm | 750 | 800 | 900 | 1000 | 1150 | 1250 | 1400 | 1700 |

|

Height |

m | 15 | 15 | 15 | 20 | 20 | 20 | 25 | 25 | |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- JUN CHANG YEAL

- Address

- #805 3cha AceHighEnd 371-5- Gasan-dong Geumcheon-gu Seoul 153-803 S.KOREA

- Product Category

- Electrical Equipment,Home Heaters

- No. of Total Employees

- 1-50

- Company introduction

-

Since its establishment in 1971, we all the employees and managements of Kang Won Boiler Manufacturing Company, Limited, have ceaselessly striven for futher advanced boiler-technology up to now.

At the result, we have been able to produce and supply various energy saving/high efficiency types of boilers and other heating apparatuses, and thus we have at last won and enjoyed excellent reputation and invincible reliability from our clients and customers home and abroad.

Production of articles of being proud of the highest quality and accurate safety: this is our sincerity and pride on our products.

- Main Markets

-

China

China

- Main Product

Related Products

Kerona kerosene heater TS-79

PTC Thermistor for Heating Element

Electric-heated hot water mat

Underfloor electricity carbon stripe coated heating film

Kerona kerosene heater KSP-229