Eco-friendly Part Washer(KHP-37)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery & Industry Equipment

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | Eco-friendly Part Washer(KHP-37) | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Eco-friendly Part Washer(KHP-37)

Introduction

- The KHP-37 washes away grease and removes impurities originating from vehicles and general machinery parts.

- The KHP-37, equipped with "VOCs Flow Circuit System", reduces VOCs during part washing. Patented in Korea (No. 00962283), the US and PCT.

- Designed for close-type chambers, in place of existing open-type ones already prohibited in the US, the innovative KHP-37 protects workers from such harmful VOCs as benzene, toluene, and xylene which are contained in solvents.

- Further, it prevents air pollution. The KHP-37 passed the SCAQMD's test to identify how much VOCs could be removed (more than 95 %).

- We received a sales permit in September 2011, the first of its kinds.

- KHP-37 technology was certified as "VOCs Reduction Technology" (No. GT-11-00230) by the Ministry of Environment in October 2011.

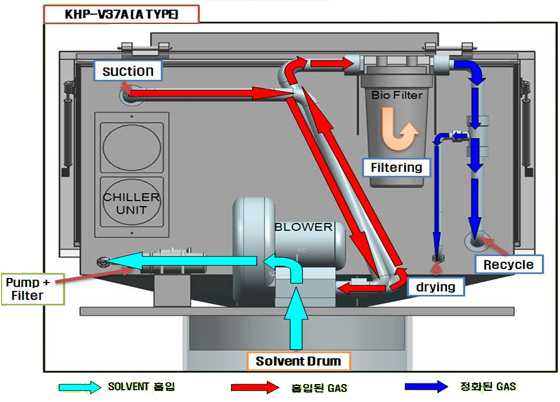

VOC Filtratioin System

-VOC Flow Circuit System

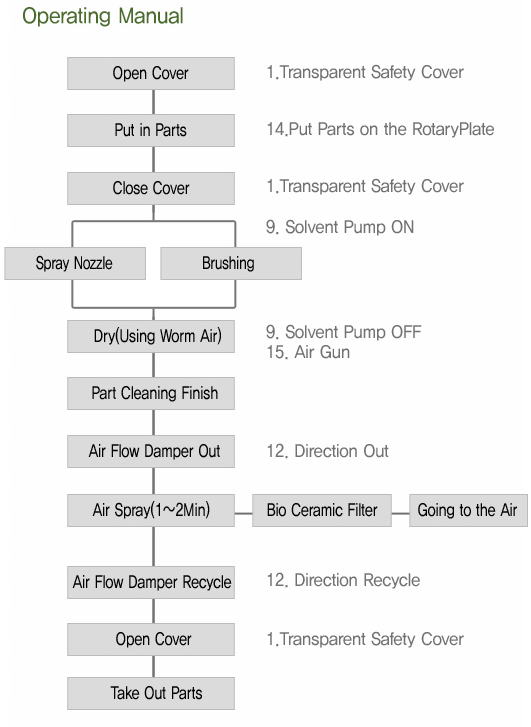

- VOCs are circulated and condensed through the recovery flow channel. While passing through the charcoal filter and ILWOO's "screens" the VOCs revert back to liquid form(become condensed). See Figure 1.

- A damper valve directs the flow of the condensed VOCs. For example, if the parts washer is in use, the Flow Circuit System recycles the condensed VOC returning it to the parts washer. When the damper valve is closed, all VOCs are directed to the bio-ceramic filter.

- When parts have been cleaned, the damper valve is adjusted along with the air handling fan to direct VOCs remaining in the parts washer to the bio-ceramic filter.

-Bio-Ceramic Filter

- Prior to opening the parts washer cover, VOCs will have been treated and mostly eliminated by the bio-ceramic filter. Running the system an additional two minutes will eliminate VOCs in the washer bay prior to opening the cover.

- ILWOO's bio-ceramic filter utilizes microorganisms that digest VOCs.

- Under normal conditions, these microorganisms live 3-4months.

- ILWOO's patented bio-ceramic filter was a joint research effort with professors at Myongji Univ. in Korea and ILWOO's own research team. In-house testing found that on average the Flow Circuit System and Bio-ceramic filter reduced more than 90% of VOC emissions compared to open-type part washers(see table 1). The research team is working on publishing the results. U.T has not validated these results.

Specification

| Model | KHP-37 |

| Material | SUS304 |

| Drum Size | 460 ID x 710h |

| Dimension | 940(L) x 640(W) x 210(H) |

| Height | 1010n |

| Washing Method | Spray Gun |

| Power | 220V/110V |

| Solvent Heater | ISA-1000(450W) |

| VOCs Filter | Chopcool / Bioceramic |

| Dryer | Hot Air |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |